2Safety Sensors / Components

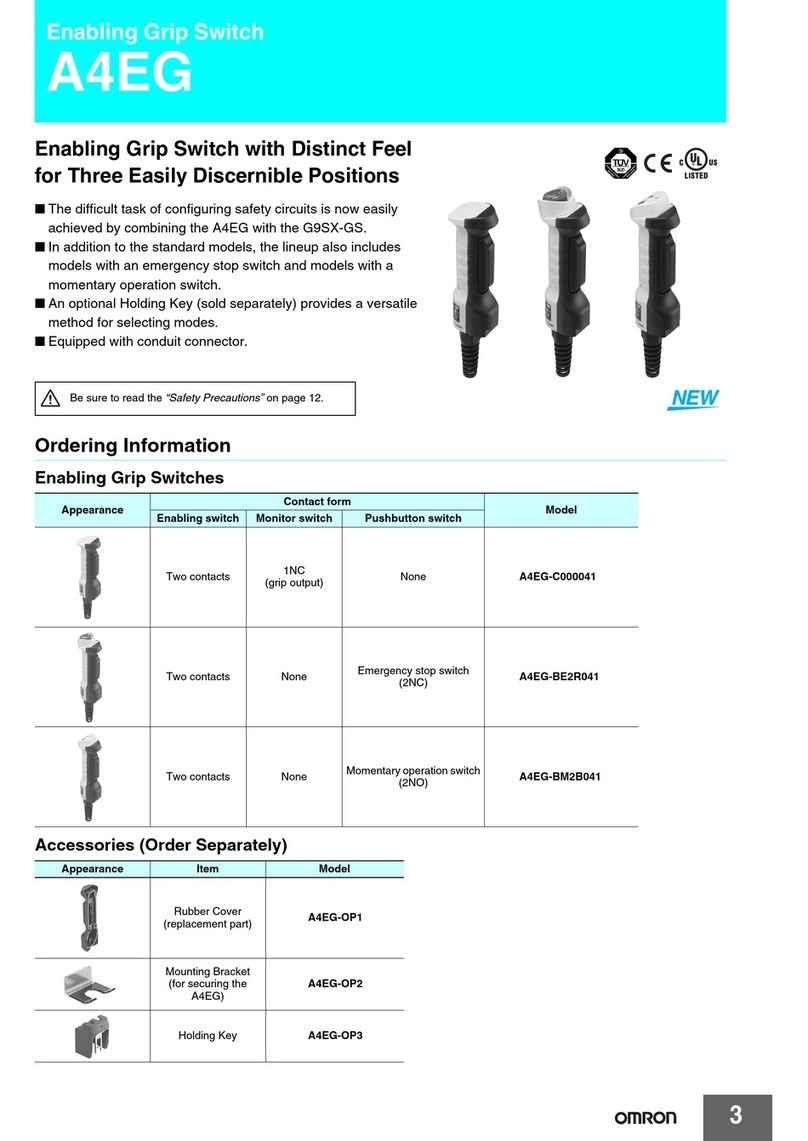

Ordering Information

Elongated Sensors Type Cable Connection Contact Configuration

F3S-TGR-NLPC-20-02 2 m pre-wired 2NC

F3S-TGR-NLPC-20-05 *

*. Preferred stock items.

5 m pre-wired 2NC

F3S-TGR-NLPC-20-10 10 pre-wired 2NC

F3S-TGR-NLPC-20-M1J8 M12, 8-pin 2NC

F3S-TGR-NLPC-21-02 2 m pre-wired 2NC/1NO

F3S-TGR-NLPC-21-05 * 5 m pre-wired 2NC/1NO

F3S-TGR-NLPC-21-10 10 pre-wired 2NC/1NO

F3S-TGR-NLPC-21-M1J8 M12, 8-pin 2NC/1NO

Small Sensor Type Cable Connection Contact Configuration

F3S-TGR-NSMC-20-02 2 m pre-wired 2NC

F3S-TGR-NSMC-20-05 *

*. Preferred stock items.

5 m pre-wired 2NC

F3S-TGR-NSMC-20-10 10 pre-wired 2NC

F3S-TGR-NSMC-20-M1J8 M12, 8-pin 2NC

F3S-TGR-NSMC-21-02 2 m pre-wired 2NC/1NO

F3S-TGR-NSMC-21-05 * 5 m pre-wired 2NC/1NO

F3S-TGR-NSMC-21-10 10 pre-wired 2NC/1NO

F3S-TGR-NSMC-21-M1J8 M12, 8-pin 2NC/1NO

Miniature Sensor Type Cable Connection Contact Configuration

F3S-TGR-NMPC-20-02 2m pre-wired 2NC

F3S-TGR-NMPC-20-05 *

*. Optional cable exit to the right is available for F3S-TGR-NMPC - types. Please contact your Omron distributor

5m pre-wired 2NC

F3S-TGR-NMPC-20-10 10m pre-wired 2NC

F3S-TGR-NMPC-20-M1J8 M12, 8pin 2NC

F3S-TGR-NMPC-21-02 2m pre-wired 2NC/1NO

F3S-TGR-NMPC-21-05 * 5m pre-wired 2NC/1NO

F3S-TGR-NMPC-21-10 10m pre-wired 2NC/1NO

F3S-TGR-NMPC-21-M1J8 M12, 8pin 2NC/1NO

E14E-EN-02+F3S-TGR-N_C+CodedTyp+Datasheet.fm Seite 2 Montag, 25. August 2008 10:56 10