D4SL-N EC

2006/42/EC

EMC 2004/108/EC

IP67

1.5 2

EN IEC60127 4A

(AC125V,1A) 3

9mm

1/2-14NPT

(

(H2S SO2NH3HNO3Cl2)

H2S SO2NH3HNO3Cl2

6

1

LOCK UNLOCK

UNLOCK LOCK

D4SL-N A UNLOCK

D4SL-N G LOCK

UNLOCK

0.2N m

LOCK

0.4 0.5 N m

D4SL-NK G 0.75 1.15 N m

D4SL-NK NK S 2.4 2.8 N m

0.75 1.15 N m

1.8 2.2 N m G1/2 M20

1.4 1.8 N m 1/2-14NPT

2

M4

4±0.1 1.5

(D4SL-NK )

0.8mm

3

D4SL-K

3

4

5

NC

DC24V E1 E2

DC24V

6

AWG24 22 0.2 0.3mm2AWG24

2A

D4SL-N

D4SL-N

XHP-10

AWG24 22 SXH-001T-P0.6

1/2-14NPT IP67

9mm

9mm

IP67

G1/2

LAPP ST-PF1/2 5380-1002 6.0 12.0mm

LS-2G

6.0 11.0mm

M20 LAPP ST-M20×1.5 5311-1020 7.0 13.0mm

1/2-14NPT LAPP ST-NPT1/2 5301-6030 6.0 12.0mm

JPK-16 GPM20

LAPP TEL 043 423 8741

http://www.ace-service.co.jp

1/2-14NPT

EMC EN1088 EN50047 GS-ET-19

EN60947-5-1 IEC60947-5-1, UL508 CSA C22.2 No.14

EN

AC-15 DC-13

AC120V DC125V

1.5A 0.22A

UL CSA

C150 R150

AC120V DC125V

1800VA 28VA

180VA 28VA

( ) 15mm

( ) 60N

1300N GS-ET-19

0.05 1m/s

5 /

100A

4A (IEC60127)

67(EN60947-5-1) ( IP00)

TYPE 4X INDOOR USE ONLY (UL, CSA)

DC5V 1mA ( )

10 55 ( )

95 RH

100

15 (AC125V 1A )

DC24V+10 /-15

-

D4SL-N |N/P/Q/R| - N 6.4 -0.27A

D4SL-N | | - N 4.8 -0.2A

2.6W 0.15A

(LED) DC24V 10mA

B10d 2,000,000

ON/OFF

a)

b)

c)

d) 24

e)

*

0120-919-066

PHS

055-982-5015

8 00 21 00 365

FA

055-977-6389

9 00 12 00/13 00 17 30

FAX

FAX 055-982-5051

Original instruction

EC Declaration of Conformity

OMRON declares that D4SL-N is in conformity with the requirements of the

following EC Directives:

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

Definition of Precautionary Information

Indicates an imminently hazardous situation

which, if not avoided, is likely to result in serious

injury or may result in death. Additio

may be severe property damage.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury or in property damage.

Precautionary Information

Always verify the operation of the safety functions

before starting the system.Not do so may result that

the safety functions may not be performed as expected

if wiring or settings are incorrect or the switch have

failed.The controlled system may continue to operate

and possibly resulting in injury or death.

Do not dismount the operation key from the

door intentionally and insert it to the switch

with the door open. Machine may start

operating and injury or death may be caused.

Do not apply force exceeding the specified maximum

holding force. Doing so may damage the switch lock

mechanism and the system may continue to operate,

possibly resulting in injury or death. Either install another

locking component (e.g., a hook) in addition to the

Switch, or use a warning measures or an indicator

showing the controlled system is locked to avoid

overloading the holding force in lock mode.

1. Environment

1-1. Do not use the switch where explosive gas, ignitable gas, or any other harmful

gasses may be present.

1-2. Do not use the switch in the oil and in the water. IP67(EN60947-5-1)

1-3. Though the switch body is protected from the ingress of dust or water, avoid

the ingress of foreign substance through the key hole on the head.

Otherwise, wear in short time or break may be caused

2. Wiring

2-1. Connect the fuse to the switch in series to prevent it from short circuit damage.

The value of the breaking current of the fuse must be increased to cover the

rated current by 150 to 200%. When using the switch with EN rating, use 4 A

fast acting fuse that complies with IEC 60127.

2-2. On the switching of general loads (125VAC/1A), do not operate three circuits or

more at the same time. Otherwise, insulation performance may be degraded.

2-3. Keep the electrical load below the rated value.

2-4.Use a metallic connector which has a threaded portion of 9 mm length or less.

2-5. Do not use metal conduit with this switch. The broken conduit hole may cause

electrical shock hazard.

2-6.Use of a 1/2-14NPT connector may result in damage to a conversion adapter,

causing defective sealing or a risk of electric shock. Do not use metallic

connectors.

2-7. Be sure to install a cover after the wiring.

Do not put the electric power when opening a cover.

Do not put the electric power when wiring.

3. Mounting

3-1. Be careful not to drop your D4SL-N, or the switch

will not fully exhibit its ability.

3-2. This may cause a risk of personal injury.

Extra care must be taken not to drop this Product

during installation..

3-3. Install operation key so that it will not hit the operator

when the door is open. Injury may be caused.

3-4.Do not use the switch as a stopper.

Be sure to install a stopper as shown in the following

illustration to prevent the edge of the operation key

from inadvertently hitting the switch directly.

4. Others

4-1. Do not disassemble or remodel your D4SL-N in any case, or the D4SL-N will

not operate normally.

4-2. Evaluate the switch under actual working conditions before permanent

installation.

The durability of the switch is seriously affected by operating conditions.

4-3. Please mention in machine manufacturer’s Instruction.

Manual that the user must not repair nor maintain the switch and must

contact machine manufacturer for them.

Precautions for Correct Use

1. About the solenoid lock type

1-1. Be sure to energize the solenoid with the door closed (with the operation key

inserted). A malfunction will occur in Solenoid lock when energizing the

solenoid before closing the door.

1-2. In the solenoid lock type, a lock is closed only when the sol enoids are energized.

A lock may be opened when the passage of an electric current to the solenoid is

stopped due to sudden power failure. Do not use the solenoid lock type for the

machine in which the inside of the door remains dangerous even after

shutdown of the machine.

2. Environment

2-1. The switch is intended for indoor use only.

2-2. Do not use your D4SL-N outdoor, or the switch will malfunction.

2-3. Do not use your D4SL-N in the atmosphere of hazardous gases (H2S, SO2, NH3,

HNO3, CI2, etc.) or high temperature and humidity, or it will cause the

imperfect closing of the contacts or the breakage thereof stemming from

corrosion.

2-4. Do not use the switch under any of the conditions mentioned below.

Frequent temperature range.

High humidity or dew condensation may be generated.

Where the switch is subject to severe vibration.

Where the metal dust, oil, or chemical is sprayed inside the door.

Where thinner is applied.

3. Storage

3-1. Do not keep the switch in dusty, humid place and any place where gas may be

present for example H2S, SO2, NH3, HNO3, Cl2.

3-2. A switch that has been stored for more than six months must be checked again

before use.

4. Using the release key (See Figure 1)

4-1. The release key is used to open a lock in the case of power failure or

emergency.

4-2. Turn the release key from the LOCK position to the UNLOCK position to

release the lock. This can open the safety door. (For the mechanical lock type

only.)

4-3.When the release key is turned to the UNLOCK position for maintenance or

other purposes, make sure to turn it back to the LOCK position before using it.

4-4. The set position of the release key at the shipping of the switch is as noted

below;

D4SL-N A : UNLOCK position D4SL-N G : LOCK position

4-5. While the release key is in the UNLOCK position, a lock is not closed and a

machine is not activated even when the door is closed in the course of

preliminary adjustment work performed inside a large machine or a

depressing type machine.

4-6. Do not use the release key when starting or stopping the machine.

4-7. The releasing of the auxiliary lock must be handled by an authorized person.

4-8. Do not apply an excessive force (of 0.2N m or more) to the threaded portion of

the release key. The release key may be damaged to the extent that it no

longer becomes operational.

4-9. To avoid an unauthorized person's access to the release mechanism, set the

release key to the LOCK position, and then seal the release key with a seal

wax (or wax coatings).

5. Installing the cover

5-1. Confirm that the seal rubber has no abnormality and then use it.

If the seal rubber is displaced or floated, or if foreign matters adhere to the seal

rubber, the seal rubber will lose its sealing capability.

5-2. Do not use any screw other than correct one, or the sealing capability of the

seal rubber will deteriorate.

6. About the hinge type door

6-1. A door is mounted near a hinge, excessive load may be imposed beyond a force

acting on the lock portion of this Equipment. This may result in damage to the

lock mechanism. Mount it to a position near a handle.

7. Mounting method

7-1. Mounting screw tightening torque loose mounting may result in malfunction.

Fasten the screws to the specified torque.

Operation key clamping screw D4SL-NK G

Operation key clamping screw

D4SL-NK ,NK S 2.4 to 2.8 N m

Conduit mounting connection

1.8 to 2.2 N m (G1/2,M20)

1.4 to 1.8 N m (1/2-14NPT)

7-2. Switch, operation key (See Figure 2)

1) The switch and operation key will be fastened to specified torque in clause 7-1

with M4 screws and washers.

2) The switch can be fastened more firmly by a stud(4mm dia., 1.5mm max height)

inserted from back side at the hole of the switch.

3) Do not use the operation key other than dedicated OMRON’s (D4SL-NK ).

Otherwise switch may be damaged.

4) Be sure that the operation key can be inserted properly to key hole with a

tolerance of ±0.8mm.

5) Insert the operation key into the key hole according to the specified “operation

key insertion radius in horizontal direction”.

6) Do not impose excessive force on the key top while the operation key is inserted

into the switch body or drop the switch with the operation key inserted to avoid

the deformation of the key or the breakage of the switch body.

7) When mounting at the side of switch body, mount the switch with 3 points

including the head.

8) Attach cap heads to any operation key holes that are not being used.

9) Do not use the operation key D4SL-K . A lock will not be closed and a machine

will not be activated.

7-3. Securing of the door (See Figure 3)

1) If the operation key is pulled in the opening direction due to a force caused by

vibration, by the door weight, or by a cushion attached to the door. The closed

door must be secured with a hook or by similar means.

7-4. Spacer (See Figure 4)

1) Do not remove the spacer. Use the switch with the spacer rotated appropriate

for the mounting direction. Lock strength will decrease when using the switch

without spacer.

8. Wiring

8-1. Example of circuit connections (See Figure 5)

1). Internal circuit of the switch inside is different according to the part

number. Please confirm the circuit diagram on the product body when

using.

2). The open circuit operating contacts are labeled with arrow marks. They are

able to used as input to the safety circuit.

3). Please make the system that can observe both the door open/close

detection switch and the lock monitor switch NC contacts close when

the lock is necessary on safety.

4). The 24VDC solenoid has a polarity. (E1: Positive (+) polarity, E2: Negative (-)

polarity)

5). Current consumption of the solenoid is different in inrush and constant.

Apply the rated working voltage to the solenoid.

8-2. Wiring (See Figure 6)

1). Do not put the electric power when wiring.

2). Do not let particles such as small piece of lead wire in the switch body when

wiring.

3). Adequate conductor size is AWG 24 to 22 (0.2 to 0.3mm2).

Do not pass a current of 2 A or more when using AWG24.

4). Wire leads as shown in the following figure. Otherwise, the switch cover d oes

not fit.

5). Do not pull on lead wires with excessive force. The wires may break.

6). Do not force the cable-side socket into the connector and D4SL-N conduit

opening. Doing so may break the crimped wires .

Be sure to insert the cable into the connector and D4SL-N conduit opening first

and then attach the socket to the cable, or to insert the other end of the cable

into the connector and the conduit opening.

Cable-side socket

(Applicable Electric Wire AWG24~22) SXH-001T-P0.6

9. Conduit opening

1). Use the connectors recommended in clause 10 and tighten the connector with

specified torque in clause 7-1. An excessive torque will bring a case breakage.

2). When using the connector size of 1/2-14NPT, apply the sealing tape between

connector and conduit opening so that the enclosure will conform to IP67.

3). Use a cable with a suitable diameter for the connector.

10. Recommendation of connector

For easy wiring, use a connector that has the screw part with 9 mm or less in

length.

Use below listed connector to secure IP67.

Size Manufacturer Type

(Short type) 6.0 to 11.0 mm

Use an optional seal packing (Type: JPK-16 or GPM20).

Tighten the seal packing to a proper tightening torque.

LAPP is a German manufacturer.

Ace Service is a Japanese manufacturer.

Before a connector of 1/2-14NPT size is used, install a supplied conversion

adapter on the switch and wrap it in seal tape.

11. Others

11-1. Please do a regular check in premeditation for this switch

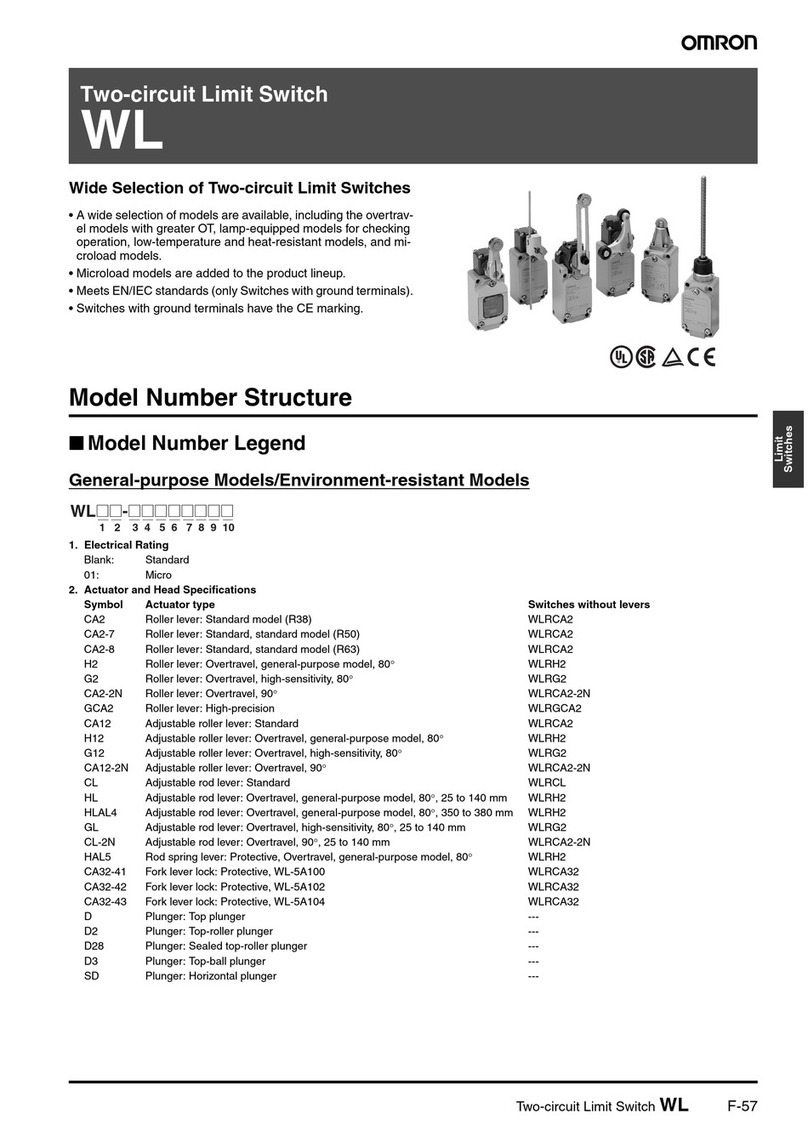

12. Technical specification

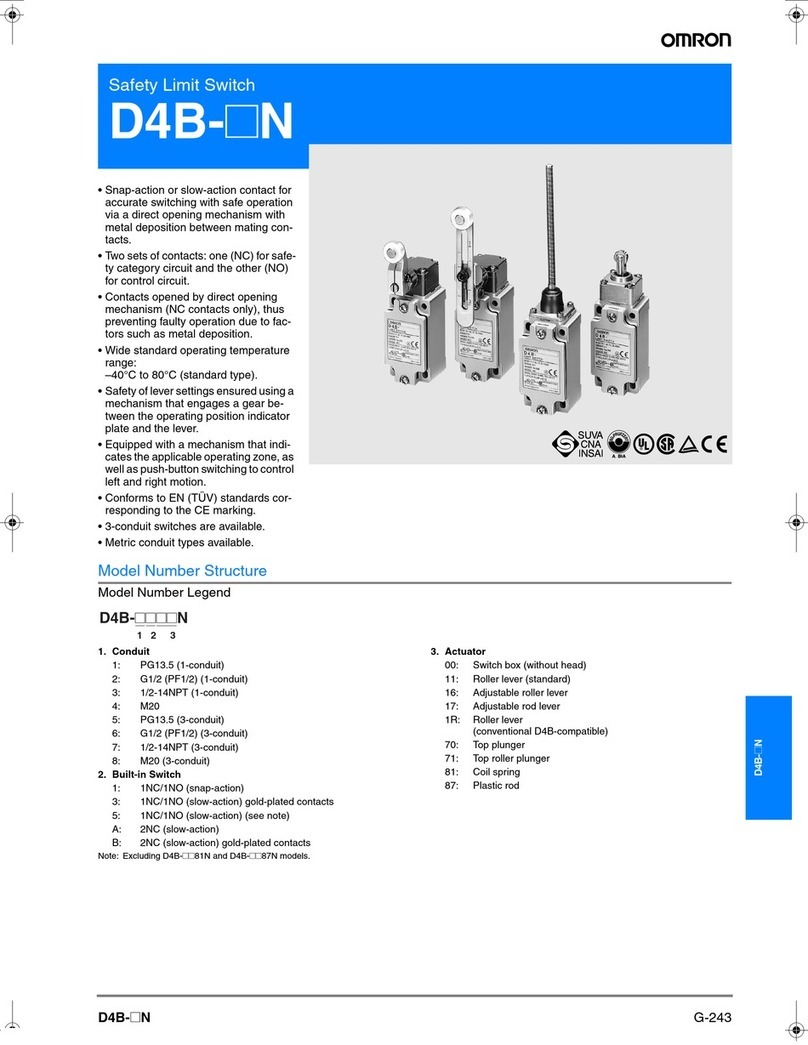

Conformity: Machine Directive, Low Voltage Directive, EMC Directive,

EN1088 EN50047,GS-ET-19

Approval EN60947-5-1 IEC60947-5-1 UL508 CSA C22.2 No.14

Utilization category AC-15/DC-13

Rated Voltage 120VAC / 125VDC

Rated Current 1.5A / 0.22A

UL, CSA electrical rating

C150 R150

Voltage 120VAC 125VDC

Volt Amp. Make 1800VA 28VA

Break 180VA 28VA

Direct opening travel (min.) 15 mm

Direct opening force (min.) 60 N

Holding force (min.) 1300N (GS-ET-19)

Operating speed 0.05 to 1 m/s

Operating frequency 5 operation / minute max.

Conditional short-circuit current 100A

Short circuit protective device Use 4 A fast acting fuse in accordance with

Enclosure rating IP67 (EN60947-5-1) (Operation key insertion face : IP00)

TYPE 4X INDOOR USE ONLY (UL, CSA)

Minimum permissible load: 5VDC, 1mA resistive load (N level: reference value)

Ambient temperature range -10 to +55

Ambient humidity (max.): 95%RH

Mechanical durability (min.) 1,000,000 operations

Electrical durability (min.) 150,000 operations

(125VAC,1A resistive load)

Solenoid Rated working voltage 24VDC+10%/-15%

Power-Current consumption

Inrush

D4SL-N |N/P/Q/R | - N Approximately 6.4W-0.27A

D4SL-N |A/B/C/D/E/F/G/H/S/T/U/V | - N

Approximately 4.8W-0.2A

Constant Approximately 2.6W-0.15A (max.)

Indicator lamp(LED) Rated voltage 24VDC

Current consumption Approximately 10mA

There is no equality between the ON/OFF motions of a contact.

The switch contacts are common use for general load and micro load but, after

switching a general load, it is impossible to switch a micro load with the same

contacts. The contact reliability would be decrease due to the rough contact

surface.

Liability for use in safety systems

OMRON shall not be responsible for conformity with any standards, codes, or

regulations that apply to the combination of the products in the

customer's application or use of the product.

Take all necessary steps to determine the suitability of the product for the systems,

machines, and equipment with which it will be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS

A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE

OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

OMRON Corporation Industrial Automation Company

Wegalaan 67-69-2132 JD Hoofddorp The Netherlands

Tel: (31)2356-81-300 / Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),Alexandra Technopark, Singapore

119967

Tel: (65) 6835-3011 / Fax: (65) 6835-2711

OMRON SCIENTIFIC TECHNOLOGIES INC.

6550 Dumbarton Circle, Fremont CA 94555-3605 U.S.A.

Tel: (1) 510-608-3400 / Fax: (1) 510-744-1442

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower, 200 Yin Cheng Zhong Road,PuDong New Area,

Shanghai, 200120, China

Tel: (86) 21-5037-2222 / Fax: (86) 21-5037-2200

Traceability Information

OMRON EUROPE B.V.

Wegalann 67-69 2132 JD Hoofddorp The Netherlands

Manufacturer

OMRON CORPORATION, Safety Device Division

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 JAPAN

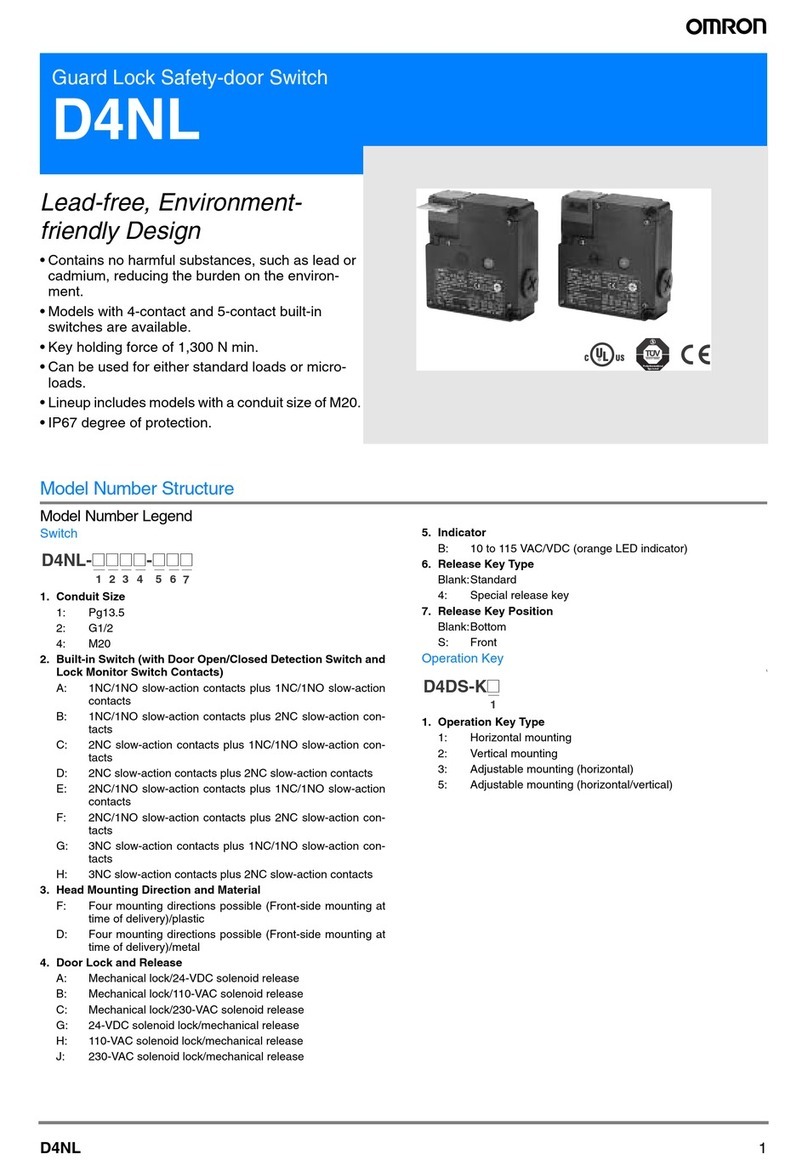

Guard Lock Safety-door Switch

Manvel d’Instrvctions

Instruction Sheet manuale d’Instruzioni

Bertriebsanleitung manuale de Instrucciones

Thank you for purchasing this D4SL-N. This INSTRUCTION MANUAL described the information such as

function, performance and how to use the product required for using the D4SL-N.

For using this product, please follow keep the precautions as shown in the following:

Ensure that this product is installed and operated by qualified personal having sufficient skills in

mechanics and electrotechnic.

Ensure that you understood this manual and that you use the product as described in this manual.

Keep this instruction manual close at hand and use it for reference during operation.

EU EU www.industrial.omron.eu/safety.

Instructions in the official EU languages and a signed EC Declaration of Conformity in English are available on our website at www.industrial.omron.eu/safety.

M4

Front

4±0.1 dia. 1.5mm high max

41.7±0.15

Side

38.7±0.1

10±0.1

41.7±0.15

4±0.1 dia. 1.5mm high max

D4SL-NK3

D4SL-NK1G/-NK2G

D4SL-NK1/-NK1S/-NK2

2-M4

15

0.1

2-M4

40

0.1

2-M4

12

0.1

or 20±0.1

Door Open/Close

Detection Switch)

Door Open/Close

Detection Switch)

D4SL-N EC

2006/42/EC

EMC 2004/108/EC

IP67

1.5 2

EN IEC60127 4A

(AC125V,1A) 3

9mm

1/2-14NPT

(

(H2S SO2NH3HNO3Cl2)

H2S SO2NH3HNO3Cl2

6

1

LOCK UNLOCK

UNLOCK LOCK

D4SL-N A UNLOCK

D4SL-N G LOCK

UNLOCK

0.2N m

LOCK

0.4 0.5 N m

D4SL-NK G 0.75 1.15 N m

D4SL-NK NK S 2.4 2.8 N m

0.75 1.15 N m

1.8 2.2 N m G1/2 M20

1.4 1.8 N m 1/2-14NPT

2

M4

4±0.1 1.5

(D4SL-NK )

0.8mm

3

D4SL-K

3

4

5

NC

DC24V E1 E2

DC24V

6

AWG24 22 0.2 0.3mm2AWG24

2A

D4SL-N

D4SL-N

XHP-10

AWG24 22 SXH-001T-P0.6

1/2-14NPT IP67

9mm

9mm

IP67

G1/2

LAPP ST-PF1/2 5380-1002 6.0 12.0mm

LS-2G

6.0 11.0mm

M20 LAPP ST-M20×1.5 5311-1020 7.0 13.0mm

1/2-14NPT LAPP ST-NPT1/2 5301-6030 6.0 12.0mm

JPK-16 GPM20

LAPP TEL 043 423 8741

http://www.ace-service.co.jp

1/2-14NPT

EMC EN1088 EN50047 GS-ET-19

EN60947-5-1 IEC60947-5-1, UL508 CSA C22.2 No.14

EN

AC-15 DC-13

AC120V DC125V

1.5A 0.22A

UL CSA

C150 R150

AC120V DC125V

1800VA 28VA

180VA 28VA

( ) 15mm

( ) 60N

1300N GS-ET-19

0.05 1m/s

5 /

100A

4A (IEC60127)

67(EN60947-5-1) ( IP00)

TYPE 4X INDOOR USE ONLY (UL, CSA)

DC5V 1mA ( )

10 55 ( )

95 RH

100

15 (AC125V 1A )

DC24V+10 /-15

-

D4SL-N |N/P/Q/R| - N 6.4 -0.27A

D4SL-N | | - N 4.8 -0.2A

2.6W 0.15A

(LED) DC24V 10mA

B10d 2,000,000

ON/OFF

a)

b)

c)

d) 24

e)

*

0120-919-066

PHS

055-982-5015

8 00 21 00 365

FA

055-977-6389

9 00 12 00/13 00 17 30

FAX

FAX 055-982-5051

Original instruction

EC Declaration of Conformity

OMRON declares that D4SL-N is in conformity with the requirements of the

following EC Directives:

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

Definition of Precautionary Information

Indicates an imminently hazardous situation

which, if not avoided, is likely to result in serious

injury or may result in death. Additio

may be severe property damage.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury or in property damage.

Precautionary Information

Always verify the operation of the safety functions

before starting the system.Not do so may result that

the safety functions may not be performed as expected

if wiring or settings are incorrect or the switch have

failed.The controlled system may continue to operate

and possibly resulting in injury or death.

Do not dismount the operation key from the

door intentionally and insert it to the switch

with the door open. Machine may start

operating and injury or death may be caused.

Do not apply force exceeding the specified maximum

holding force. Doing so may damage the switch lock

mechanism and the system may continue to operate,

possibly resulting in injury or death. Either install another

locking component (e.g., a hook) in addition to the

Switch, or use a warning measures or an indicator

showing the controlled system is locked to avoid

overloading the holding force in lock mode.

1. Environment

1-1. Do not use the switch where explosive gas, ignitable gas, or any other harmful

gasses may be present.

1-2. Do not use the switch in the oil and in the water. IP67(EN60947-5-1)

1-3. Though the switch body is protected from the ingress of dust or water, avoid

the ingress of foreign substance through the key hole on the head.

Otherwise, wear in short time or break may be caused

2. Wiring

2-1. Connect the fuse to the switch in series to prevent it from short circuit damage.

The value of the breaking current of the fuse must be increased to cover the

rated current by 150 to 200%. When using the switch with EN rating, use 4 A

fast acting fuse that complies with IEC 60127.

2-2. On the switching of general loads (125VAC/1A), do not operate three circuits or

more at the same time. Otherwise, insulation performance may be degraded.

2-3. Keep the electrical load below the rated value.

2-4.Use a metallic connector which has a threaded portion of 9 mm length or less.

2-5. Do not use metal conduit with this switch. The broken conduit hole may cause

electrical shock hazard.

2-6.Use of a 1/2-14NPT connector may result in damage to a conversion adapter,

causing defective sealing or a risk of electric shock. Do not use metallic

connectors.

2-7. Be sure to install a cover after the wiring.

Do not put the electric power when opening a cover.

Do not put the electric power when wiring.

3. Mounting

3-1. Be careful not to drop your D4SL-N, or the switch

will not fully exhibit its ability.

3-2. This may cause a risk of personal injury.

Extra care must be taken not to drop this Product

during installation..

3-3. Install operation key so that it will not hit the operator

when the door is open. Injury may be caused.

3-4.Do not use the switch as a stopper.

Be sure to install a stopper as shown in the following

illustration to prevent the edge of the operation key

from inadvertently hitting the switch directly.

4. Others

4-1. Do not disassemble or remodel your D4SL-N in any case, or the D4SL-N will

not operate normally.

4-2. Evaluate the switch under actual working conditions before permanent

installation.

The durability of the switch is seriously affected by operating conditions.

4-3. Please mention in machine manufacturer’s Instruction.

Manual that the user must not repair nor maintain the switch and must

contact machine manufacturer for them.

Precautions for Correct Use

1. About the solenoid lock type

1-1. Be sure to energize the solenoid with the door closed (with the operation key

inserted). A malfunction will occur in Solenoid lock when energizing the

solenoid before closing the door.

1-2. In the solenoid lock type, a lock is closed only when the sol enoids are energized.

A lock may be opened when the passage of an electric current to the solenoid is

stopped due to sudden power failure. Do not use the solenoid lock type for the

machine in which the inside of the door remains dangerous even after

shutdown of the machine.

2. Environment

2-1. The switch is intended for indoor use only.

2-2. Do not use your D4SL-N outdoor, or the switch will malfunction.

2-3. Do not use your D4SL-N in the atmosphere of hazardous gases (H2S, SO2, NH3,

HNO3, CI2, etc.) or high temperature and humidity, or it will cause the

imperfect closing of the contacts or the breakage thereof stemming from

corrosion.

2-4. Do not use the switch under any of the conditions mentioned below.

Frequent temperature range.

High humidity or dew condensation may be generated.

Where the switch is subject to severe vibration.

Where the metal dust, oil, or chemical is sprayed inside the door.

Where thinner is applied.

3. Storage

3-1. Do not keep the switch in dusty, humid place and any place where gas may be

present for example H2S, SO2, NH3, HNO3, Cl2.

3-2. A switch that has been stored for more than six months must be checked again

before use.

4. Using the release key (See Figure 1)

4-1. The release key is used to open a lock in the case of power failure or

emergency.

4-2. Turn the release key from the LOCK position to the UNLOCK position to

release the lock. This can open the safety door. (For the mechanical lock type

only.)

4-3.When the release key is turned to the UNLOCK position for maintenance or

other purposes, make sure to turn it back to the LOCK position before using it.

4-4. The set position of the release key at the shipping of the switch is as noted

below;

D4SL-N A : UNLOCK position D4SL-N G : LOCK position

4-5. While the release key is in the UNLOCK position, a lock is not closed and a

machine is not activated even when the door is closed in the course of

preliminary adjustment work performed inside a large machine or a

depressing type machine.

4-6. Do not use the release key when starting or stopping the machine.

4-7. The releasing of the auxiliary lock must be handled by an authorized person.

4-8. Do not apply an excessive force (of 0.2N m or more) to the threaded portion of

the release key. The release key may be damaged to the extent that it no

longer becomes operational.

4-9. To avoid an unauthorized person's access to the release mechanism, set the

release key to the LOCK position, and then seal the release key with a seal

wax (or wax coatings).

5. Installing the cover

5-1. Confirm that the seal rubber has no abnormality and then use it.

If the seal rubber is displaced or floated, or if foreign matters adhere to the seal

rubber, the seal rubber will lose its sealing capability.

5-2. Do not use any screw other than correct one, or the sealing capability of the

seal rubber will deteriorate.

6. About the hinge type door

6-1. A door is mounted near a hinge, excessive load may be imposed beyond a force

acting on the lock portion of this Equipment. This may result in damage to the

lock mechanism. Mount it to a position near a handle.

7. Mounting method

7-1. Mounting screw tightening torque loose mounting may result in malfunction.

Fasten the screws to the specified torque.

Operation key clamping screw D4SL-NK G

Operation key clamping screw

D4SL-NK ,NK S 2.4 to 2.8 N m

Conduit mounting connection

1.8 to 2.2 N m (G1/2,M20)

1.4 to 1.8 N m (1/2-14NPT)

7-2. Switch, operation key (See Figure 2)

1) The switch and operation key will be fastened to specified torque in clause 7-1

with M4 screws and washers.

2) The switch can be fastened more firmly by a stud(4mm dia., 1.5mm max height)

inserted from back side at the hole of the switch.

3) Do not use the operation key other than dedicated OMRON’s (D4SL-NK ).

Otherwise switch may be damaged.

4) Be sure that the operation key can be inserted properly to key hole with a

tolerance of ±0.8mm.

5) Insert the operation key into the key hole according to the specified “operation

key insertion radius in horizontal direction”.

6) Do not impose excessive force on the key top while the operation key is inserted

into the switch body or drop the switch with the operation key inserted to avoid

the deformation of the key or the breakage of the switch body.

7) When mounting at the side of switch body, mount the switch with 3 points

including the head.

8) Attach cap heads to any operation key holes that are not being used.

9) Do not use the operation key D4SL-K . A lock will not be closed and a machine

will not be activated.

7-3. Securing of the door (See Figure 3)

1) If the operation key is pulled in the opening direction due to a force caused by

vibration, by the door weight, or by a cushion attached to the door. The closed

door must be secured with a hook or by similar means.

7-4. Spacer (See Figure 4)

1) Do not remove the spacer. Use the switch with the spacer rotated appropriate

for the mounting direction. Lock strength will decrease when using the switch

without spacer.

8. Wiring

8-1. Example of circuit connections (See Figure 5)

1). Internal circuit of the switch inside is different according to the part

number. Please confirm the circuit diagram on the product body when

using.

2). The open circuit operating contacts are labeled with arrow marks. They are

able to used as input to the safety circuit.

3). Please make the system that can observe both the door open/close

detection switch and the lock monitor switch NC contacts close when

the lock is necessary on safety.

4). The 24VDC solenoid has a polarity. (E1: Positive (+) polarity, E2: Negative (-)

polarity)

5). Current consumption of the solenoid is different in inrush and constant.

Apply the rated working voltage to the solenoid.

8-2. Wiring (See Figure 6)

1). Do not put the electric power when wiring.

2). Do not let particles such as small piece of lead wire in the switch body when

wiring.

3). Adequate conductor size is AWG 24 to 22 (0.2 to 0.3mm2).

Do not pass a current of 2 A or more when using AWG24.

4). Wire leads as shown in the following figure. Otherwise, the switch cover d oes

not fit.

5). Do not pull on lead wires with excessive force. The wires may break.

6). Do not force the cable-side socket into the connector and D4SL-N conduit

opening. Doing so may break the crimped wires .

Be sure to insert the cable into the connector and D4SL-N conduit opening first

and then attach the socket to the cable, or to insert the other end of the cable

into the connector and the conduit opening.

Cable-side socket

(Applicable Electric Wire AWG24~22) SXH-001T-P0.6

9. Conduit opening

1). Use the connectors recommended in clause 10 and tighten the connector with

specified torque in clause 7-1. An excessive torque will bring a case breakage.

2). When using the connector size of 1/2-14NPT, apply the sealing tape between

connector and conduit opening so that the enclosure will conform to IP67.

3). Use a cable with a suitable diameter for the connector.

10. Recommendation of connector

For easy wiring, use a connector that has the screw part with 9 mm or less in

length.

Use below listed connector to secure IP67.

Size Manufacturer Type

(Short type) 6.0 to 11.0 mm

Use an optional seal packing (Type: JPK-16 or GPM20).

Tighten the seal packing to a proper tightening torque.

LAPP is a German manufacturer.

Ace Service is a Japanese manufacturer.

Before a connector of 1/2-14NPT size is used, install a supplied conversion

adapter on the switch and wrap it in seal tape.

11. Others

11-1. Please do a regular check in premeditation for this switch

12. Technical specification

Conformity: Machine Directive, Low Voltage Directive, EMC Directive,

EN1088 EN50047,GS-ET-19

Approval EN60947-5-1 IEC60947-5-1 UL508 CSA C22.2 No.14

Utilization category AC-15/DC-13

Rated Voltage 120VAC / 125VDC

Rated Current 1.5A / 0.22A

UL, CSA electrical rating

C150 R150

Voltage 120VAC 125VDC

Volt Amp. Make 1800VA 28VA

Break 180VA 28VA

Direct opening travel (min.) 15 mm

Direct opening force (min.) 60 N

Holding force (min.) 1300N (GS-ET-19)

Operating speed 0.05 to 1 m/s

Operating frequency 5 operation / minute max.

Conditional short-circuit current 100A

Short circuit protective device Use 4 A fast acting fuse in accordance with

Enclosure rating IP67 (EN60947-5-1) (Operation key insertion face : IP00)

TYPE 4X INDOOR USE ONLY (UL, CSA)

Minimum permissible load: 5VDC, 1mA resistive load (N level: reference value)

Ambient temperature range -10 to +55

Ambient humidity (max.): 95%RH

Mechanical durability (min.) 1,000,000 operations

Electrical durability (min.) 150,000 operations

(125VAC,1A resistive load)

Solenoid Rated working voltage 24VDC+10%/-15%

Power-Current consumption

Inrush

D4SL-N |N/P/Q/R | - N Approximately 6.4W-0.27A

D4SL-N |A/B/C/D/E/F/G/H/S/T/U/V | - N

Approximately 4.8W-0.2A

Constant Approximately 2.6W-0.15A (max.)

Indicator lamp(LED) Rated voltage 24VDC

Current consumption Approximately 10mA

There is no equality between the ON/OFF motions of a contact.

The switch contacts are common use for general load and micro load but, after

switching a general load, it is impossible to switch a micro load with the same

contacts. The contact reliability would be decrease due to the rough contact

surface.

Liability for use in safety systems

OMRON shall not be responsible for conformity with any standards, codes, or

regulations that apply to the combination of the products in the

customer's application or use of the product.

Take all necessary steps to determine the suitability of the product for the systems,

machines, and equipment with which it will be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS

A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE

OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

OMRON Corporation Industrial Automation Company

Wegalaan 67-69-2132 JD Hoofddorp The Netherlands

Tel: (31)2356-81-300 / Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),Alexandra Technopark, Singapore

119967

Tel: (65) 6835-3011 / Fax: (65) 6835-2711

OMRON SCIENTIFIC TECHNOLOGIES INC.

6550 Dumbarton Circle, Fremont CA 94555-3605 U.S.A.

Tel: (1) 510-608-3400 / Fax: (1) 510-744-1442

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower, 200 Yin Cheng Zhong Road,PuDong New Area,

Shanghai, 200120, China

Tel: (86) 21-5037-2222 / Fax: (86) 21-5037-2200

Traceability Information

OMRON EUROPE B.V.

Wegalann 67-69 2132 JD Hoofddorp The Netherlands

Manufacturer

OMRON CORPORATION, Safety Device Division

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 JAPAN

Guard Lock Safety-door Switch

Manvel d’Instrvctions

Instruction Sheet manuale d’Instruzioni

Bertriebsanleitung manuale de Instrucciones

Thank you for purchasing this D4SL-N. This INSTRUCTION MANUAL described the information such as

function, performance and how to use the product required for using the D4SL-N.

For using this product, please follow keep the precautions as shown in the following:

Ensure that this product is installed and operated by qualified personal having sufficient skills in

mechanics and electrotechnic.

Ensure that you understood this manual and that you use the product as described in this manual.

Keep this instruction manual close at hand and use it for reference during operation.

EU EU www.industrial.omron.eu/safety.

Instructions in the official EU languages and a signed EC Declaration of Conformity in English are available on our website at www.industrial.omron.eu/safety.

4±0.1 dia. 1.5mm high max

4±0.1 dia. 1.5mm high max

E1

()

33

34

( )

64 63

7

3

1

10

8

4

2

9

5

6

r D4SL-N N -D

LED

Lock Monitor Switch)

To Safety Circuit

To Control Circuit

To Safety Circuit

Door Open/Clos

Detection Switch)

To Control Circuit

E1

()

31

22

32

42

( )

41

62 61

7

3

1

10

8

4

2

9

5

6

for D4SL-N V

Lock Monitor Switch)

To Control Circui

To Safety Circuit

Door Open/Close

Detection Switch)

To Control Circuit

AND