A4EG

12

Safety Precautions

!WARNING

•This product is a switch for teaching the machine such as robot in

hazardous area. The machine is allowed to operate only when

operating the switch continuously. Configure the system so that the

machine can be operated only at position 2.

•Apply load current not to exceed the rated value.

•Do not use the switch submerged in oil or water or in locations

continuously subject to splashes of oil or water. Doing so may

result in oil or water entering the switch.

•Do not use the switch in locations where explosive or flammable

gasses may be present.

•Mount the switch securely to prevent it from falling. Otherwise,

injuries may occur.

•The durability of the switch is greatly influenced by the switching

conditions. Always test the switch under actual conditions before

application and use it in a switching circuit for which there are no

problems with performance.

•Always attach the cover after completing wiring and before using

the switch. Electric shock may occur if the switch is used without

the cover attached.

•The user must not maintain or repair equipment incorporating the

switch. Contact the manufacturer of the equipment for any

maintenance or repairs required.

•Do not disassemble or remodel the switch in any case, or the

switch will not operate normally.

•Do not override by inserting the Holding Key itself in the door

switch.

•Configure the circuit so that the machine does not operate when

operating the Enabling Switch while the Holding Key is being

inserted in the door switch.

•Do not impose excessive vibration or shock on the Door Switch

while the Holding Key is inserted. Excessive vibration or shock

may cause the Switch to fail or break.

•Do not incline and pull the switch body or do not impose shock on

the switch body in the directions shown with the arrows in Fig.1.

Otherwise, the switch may be damaged and may not operate

properly.

•Refer to the D4NS Safety-door Switch Datasheet and Instruction

Sheet about the storage, ambient conditions, the details and

handling of the Switch.

•Do not hold the Enabling Switch Device at Position 2 by any other

methods except for handling. Otherwise, the original function of the

Enabling Switch Device is not worked.

Operating Environment

•This switch is designed for use indoors. Using the switch outdoors

may damage it.

•The switch contacts can be used with either standard loads or

microloads. Once the contact be used to switch smaller loads. The

contact surfaces will become rough once they have been used and

contact reliability for smaller loads may be reduced.

•Do not use the switch in the following locations.

•Locations where the interior of the Protective Door may into

direct contact with cutting chips, metal filings, oil chemicals

•Locations subject to detergents, thinners, or other solvents

•Locations subject to sudden temperature changes

•Locations subject to high humidity and condensation

•Locations subject to severe vibration

•Do not use the switch where corrosive gasses (e.g.,H2S, SO2,

NH3,HNO3, or Cl2) are present or in locations subject to high

temperature and humidity. Doing so may result in damage to the

switch as a result of contact failure or corrosion.

•Do not store the switch where corrosive gasses (e.g.,H2S, SO2,

NH3,HNO3, or Cl2) or dust are present or in high temperature and

humidity.

•If the switch is not turned ON and OFF for a long period of time,

contact resistance may be increased or continuity failure may

occur due to contact oxidation.

Mounting Method

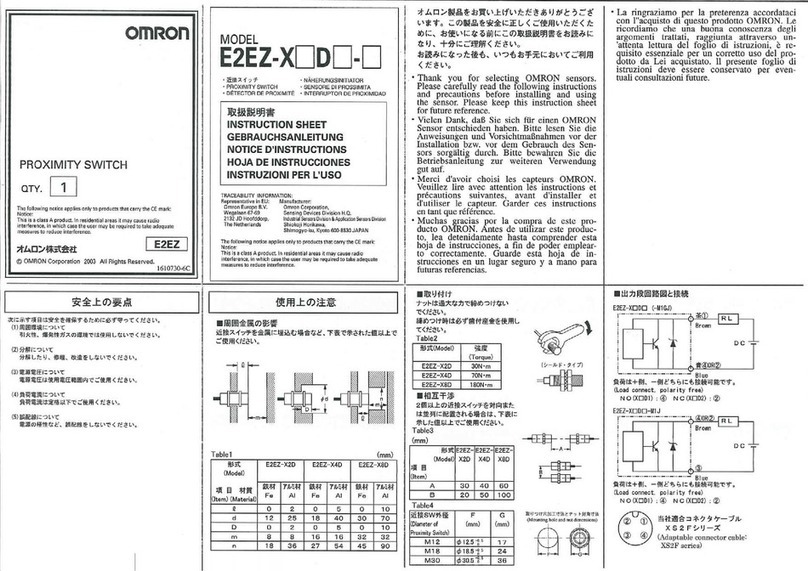

Specified Tightening Torque

Loose screws may result in malfunction. Tighten the screws at the

specified torques.

Cover Mounting

•Dislocation of the seal rubber or foreign substance on the seal

rubber reduces seal performance of the switch. Mount the cover

after confirming that there is no abnormality on the seal rubber. If

the seal rubber cracks or breaks, replace the Cover with a new one

(A4EG-OP1 Rubber Cover, separately sold).

•Do not touch the rubber boot with sharp objects. Otherwise, the

rubber boot may break and the operating characteristics and the

seal performance may not be satisfied.

Installing Mounting Bracket

•Securely install the Mounting Bracket using M5 screws and

washers and tighten them to a torque of 2.4 to 2.8 N·m.

Always verify the operation of the safety functions before

starting the system. Not doing so may result in the safety

functions not performing as expected if the wiring or

settings are incorrect or the switches have failed.

Do not drop the switch. Doing so may damage the switch

and the system may continue to operate, possibly

causing injury or death.

Precautions for Safe Use

Arrowindicates

insertion-pull direction.

Holding Key

A4EG-OP3

(sold separately)

D4NS (sold separately)

A4EG

No operation

Insertion-pull direction

(Perpendicular direction)

No operation

No operation No operation

Top position

Mounting surface

Magnified View

Fig. 1

Precautions for Correct Use

Item Specified torque

Cover mounting screw 1.1 to 1.3 N·m

Terminal screw 0.4 to 0.5 N·m

Holding Key mounting screw 0.5 to 0.7 N·m

Conduit Connector mounting

(Conforming spanner 27 mm

(width across flats)) 2.0 to 2.4 N·m

Mounting Bracket 2.4 to 2.8 N·m

Seal Cover, A4EG-OP1 (sold separately)

Rubber boot Seal rubber