G-214 Safety Sensors / Components

Safety Precautions

Refer to OMRON SAFETY COMPONENTS SERIES (Y106) for

common precautions for Switches and Safety Limit Switches.

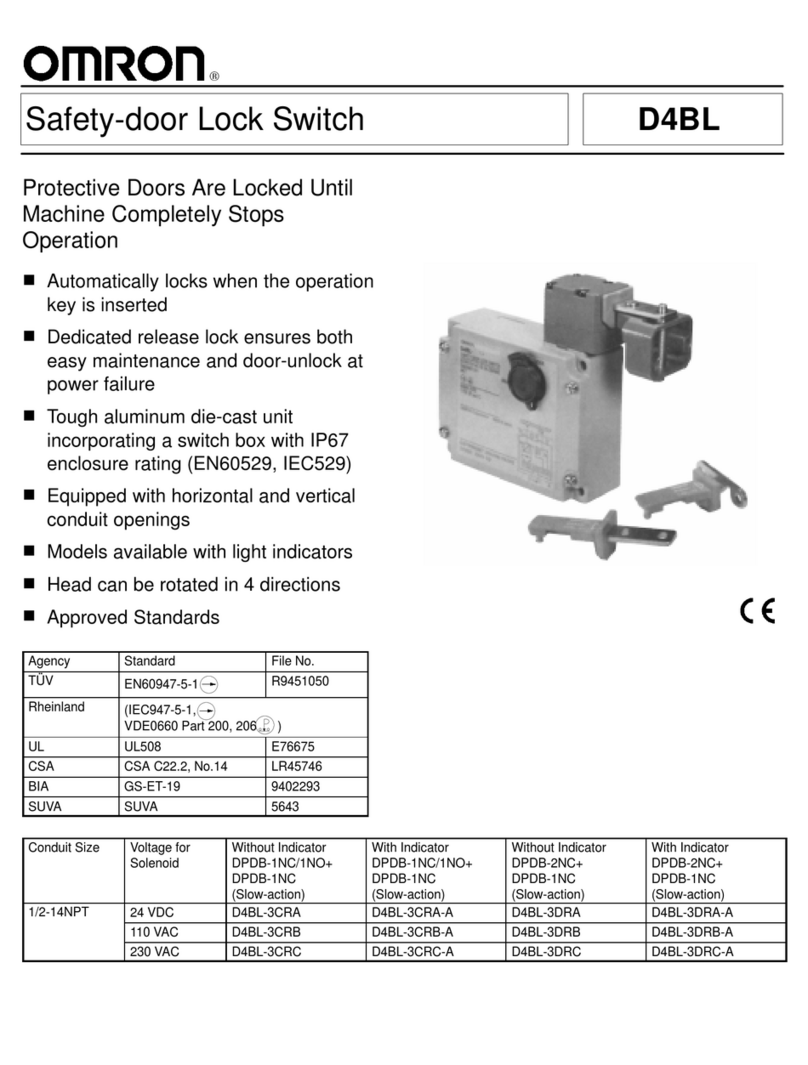

Do not use metal connectors or metal conduits with this Switch.

Doing so may occasionally result in electric shock.

Precautions for Safe Use

•Do not drop the

Switch

. Doing so may result in the

Switch

not

performing to its full capacity.

•Do not attempt to disassemble or modify the

Switch

. Doing so may

cause the

Switch

to malfunction.

•Do not use the

Switch

where explosive gas, flammable gas, or any

other hazardous gas may be present.

•Install the Switch in a location away from close body contact. Not

doing so may result in malfunction.

•

Do not use the Switch submerged in oil or water, or in locations

continuously subject to splashes of oil or water. Doing so may result

in oil or water entering the Switch interior. (The IP67 degree of

protection specification for the Switch refers to water penetration

while the Switch is submersed in water for a specified period of

time.)

•Protect the head from foreign material. Subjecting the head to

foreign material may result in premature wear or damage to the

Switch. Although the switch body is protected from penetration by

dust or water, the head is not protected from penetration by minute

particles or water.

•Turn the power OFF before wiring. Doing so may result in electric

shock.

•Install a cover after wiring. Not doing so may result in electric

shock.

•Connect a fuse to the Switch in series to protect the Switch from

short-circuit damage. Use a fuse with a breaking current 1.5 to 2

times larger than the rated current. To conform to EN ratings, use

an IEC60269-compliant 10-A fuse type gI or gG.

•Do not switch circuits for two or more standard loads (250 VAC,

3 A) at the same time. Doing so may adversely affect insulation

performance.

•The durability of the Switch is greatly affected by operating

conditions. Evaluate the Switch under actual working conditions

before permanent installation and use within a number of switching

operations that will not adversely affect the Switch’s performance.

•Be sure to indicate in the machine manufacturer’s instruction

manual that the user must not attempt to repair or maintain the

Switch and must contact the machine manufacturer for any repairs

or maintenance.

•If the Switch is to be used in an emergency stop circuit or in a

safety circuit for preventing accidents resulting in injuries or deaths,

use a model that has an NC contact equipped with a direct opening

mechanism and make sure that the Switch operates in the direct

opening mode.

Precautions for Correct Use

Environment

•The Switch is intended for indoor use only.

•Do not use the Switch outdoors. Doing so may cause the Switch to

malfunction.

•Do not use the Switch where hazardous gases (e.g., H2S, SO2,

NH3, HNO3, CI2) are present or in locations subject to high

temperature and humidity. Doing so may result in damage to the

Switch caused by contact failure or corrosion.

•Do not use the Switch under any of the following conditions.

•Locations subject to extreme temperature changes.

•Locations where high humidity or condensation may occur.

•Locations subject to excessive vibration.

•Locations where metal dust, processing waste, oil, or chemicals

may penetrate through the protective door.

•Locations subject to detergents, thinner, or other solvents.

Mounting Method

Mounting Screw Tightening Torque

Tighten each of the screws to the specified torque. Loose screws

may result in malfunction of the Switch within a short time.

Switch Mounting

•Mount the Switch using M4 screws and washers and tighten the

screws to the specified torque.

•For safety, use screws that cannot be easily removed, or use an

equivalent measure to ensure that the Switch is secure.

•Secure the Switch with two M4 bolts and washers. Provide studs

with a diameter of 4−0.05/−0.15 and a height of 4.8 mm max. at two

places, inserting into the holes at the bottom of the Switch as

shown below so that the Switch is firmly fixed at four points.

Switch Mounting Holes

•Mount the shaft or arm lever securely with a one-way screw, or an

equivalent so that the shaft or arm lever cannot be easily removed.

•Align the rotational center of the shaft with the door, so that the

switch shaft and head will not be subjected to mechanical stress

when the door opens or closes.

Do not impose a force of 50 N or more on the shaft.

Be sure that the arm lever and door are mounted as shown in the fol-

lowing diagram so that the arm lever and head are not subjected to

mechanical stress when the door opens or closes.

CAUTION

Terminal screw 0.6 to 0.8 N·m

Cover clamping screw 0.5 to 0.7 N·m

Head clamping screw 0.5 to 0.6 N·m

Arm lever clamping screw 1.6 to 1.8 N·m

Body clamping screw 0.5 to 0.7 N·m

Conduit mounting connection, M12

adaptor 1.8 to 2.2 N·m

1.4 to 1.8 N·m (1/2-14NPT)

Cap screw 1.3 to 1.7 N·m

22±0.1

47±0.1

20±0.1

22±0.1

2.5±0.1 Two, M4

−0.15

4

−0.05

dia.

Hei

ht: 4.8 max.

42±0.1

39±0.1

20±0.1

22±0.1

40±0.1

42±0.1

2.5±0.1

5.35±0.1

Two, M4

−0.15

4

−0.05

dia.

Height: 4.8 max.

One-conduit Type

Two-conduit Type

F502-EN2-04.book Seite 214 Dienstag, 26. Juli 2005 5:48 17