Long-life Two-circuit Limit Switch WLM@F-107

Limit

Switches

Precautions

■Correct Use

When wiring terminal screws, use M4 round crimp terminals and

tighten screws to the recommended torque. Wiring with broken

wires, or the incorrect crimp terminals, or not tightening screws to the

recommended torque can lead to short-circuits, leakage current, and

fire.

When performing internal wiring there is a chance of short-circuit,

leakage current, or fire, so be sure to protect the inside of the Switch

from splashes of oil or water, corrosive gases, and cutting powder.

Using an inappropriate connector or assembling Switches incorrectly

(assembly, tightening torque) can result in malfunction, leakage cur-

rent, or fire, so be sure to read the instruction manual thoroughly

beforehand.

Even when the connector is assembled and set correctly, the end of

the cable and the inside of the Switch may come in contact. This can

lead to malfunction, leakage current, or fire, so be sure to protect the

end of the cable from splashes of oil or water and corrosive gases.

Environmental Precautions

When the Switch is used in locations subject to splashes of water or

oil, the material of the seal, which ensures the sealing properties of

the Switch, may undergo changes in shape and quality. This is due to

deterioration (including expansion and contraction), and may result in

reduced performance, ineffective return, and ineffective sealing

(leading to ineffective contact, insulation, leakage current, and fire).

Confirm the possible effects of the operating environment on the

Switch before use.

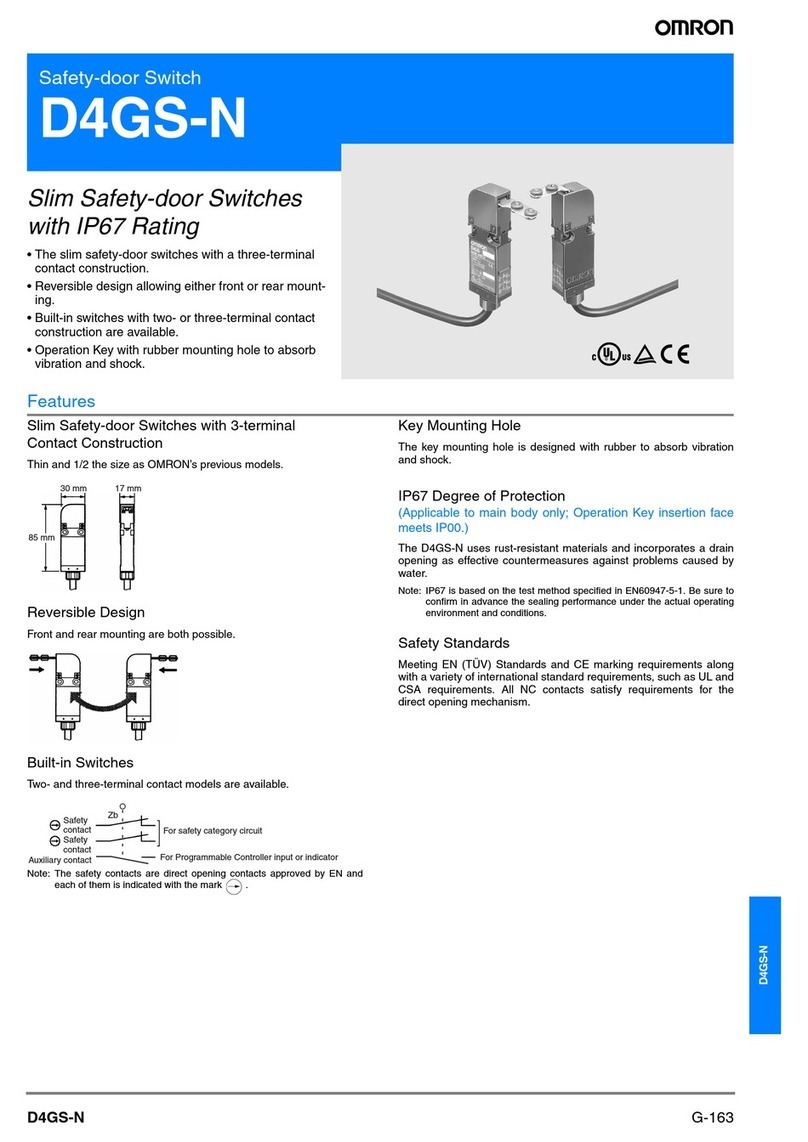

Built-in Switch

Do not replace the built-in switch. If the position of the insulation

sheet moves (separator), the insulation may become ineffective.

Tightening Torque

If screws are too loose they can lead to an early malfunction of the

Switch, so ensure that all screws are tightened using the correct

torque.

In particular, when changing the direction of the Head, make sure

that all screws are tightened again to the correct torque. Do not allow

foreign objects to fall into the Switch.

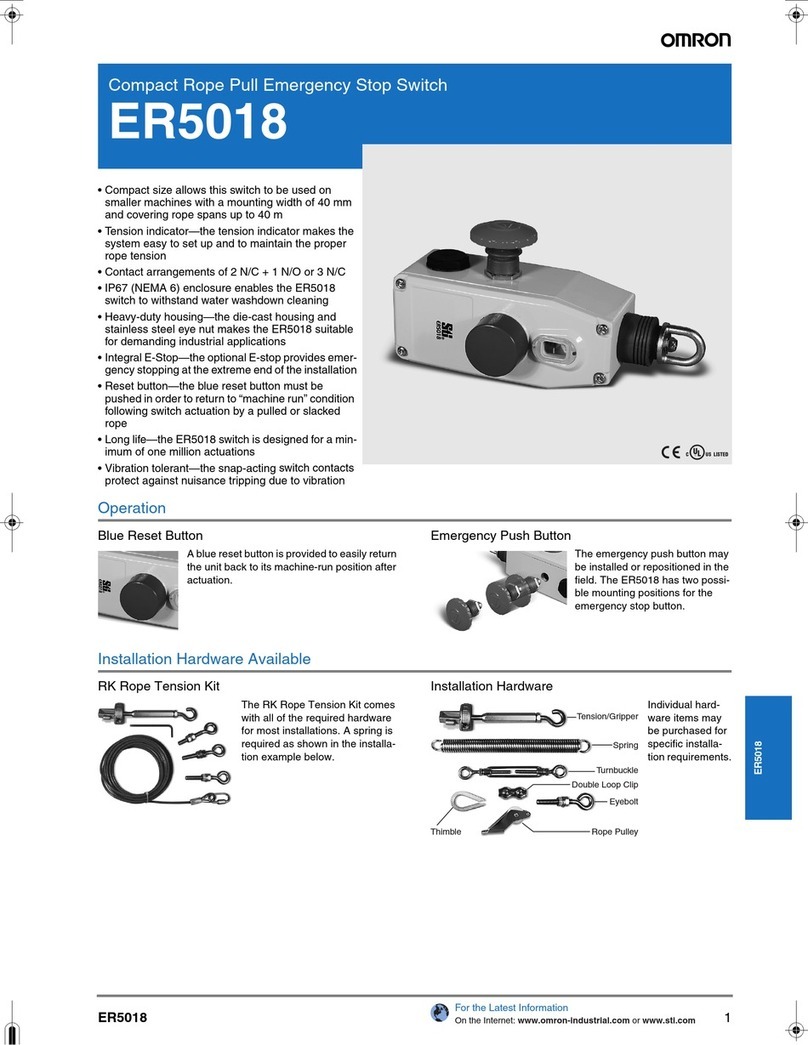

Installing the Switch

To install the Switch, make a mounting panel, as shown in the follow-

ing diagram, and tighten screws using the correct torque.

Connectors

Either the easy-to-use Allen-head nut or the SC Connector can be

used as connectors. To ensure high-sealing properties, use the SC

Connector. (SC-1M to -5M and others.)

No. Type Torque

1 Head mounting screw 0.78 to 0.88 N·m

2 Cover mounting screw 1.18 to 1.37 N·m

3 Allen-head bolt

(for securing the lever)

4.90 to 5.88 N·m

4 Terminal screw 0.59 to 0.78 N·m

5 Connector 1.77 to 2.16 N·m

6 Main Unit screws 4.90 to 5.88 N·m

0

Four, 5.2+0.2 dia. mounting holes or M5 taps