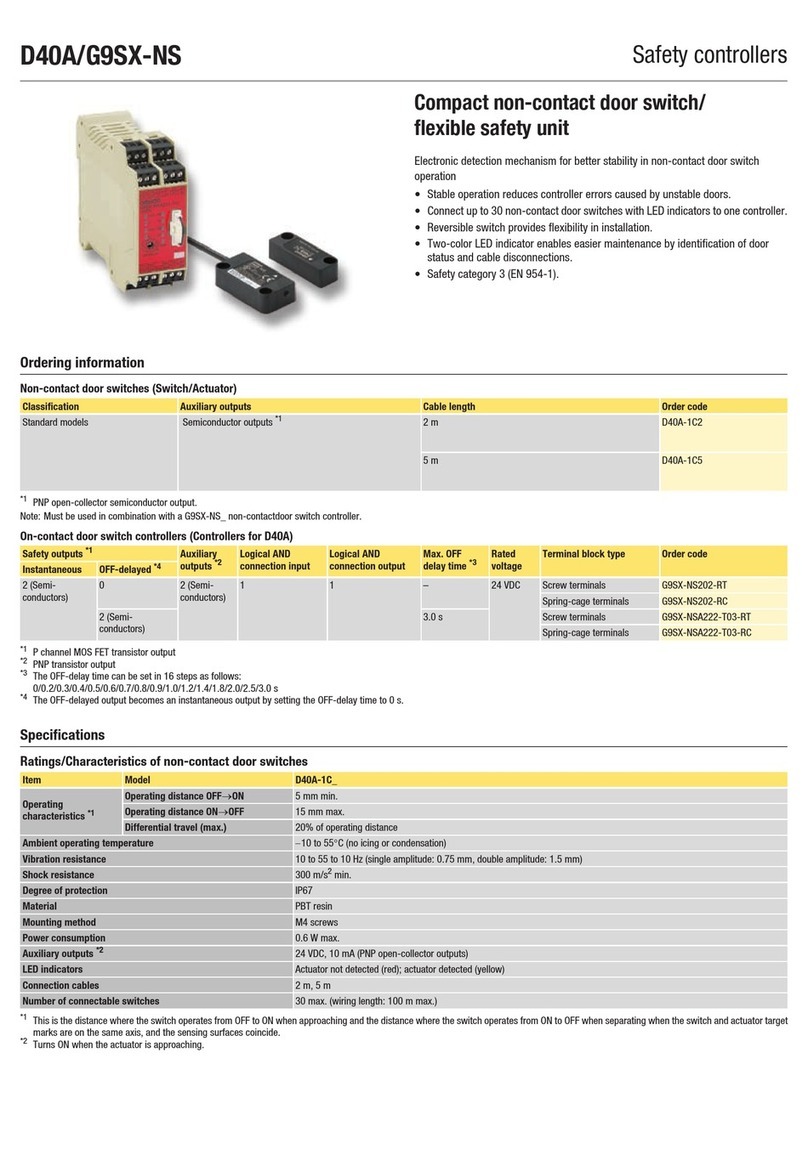

Compact Non-Contact Door Switch D40A/Flexible Safety Unit G9SX-NS 9

Specifications

■Ratings/Characteristics of Non-contact Door Switches

Note: 1. This is the distance where the switch operates from OFF to ON when approaching and the distance where the switch operates from ON

to OFF when separating when the switch and actuator target marks are on the same axis, and the sensing surfaces coincide.

2. Turns ON when the actuator is approaching.

3. For details, refer to item 5 on page 29.

Item Model D40A-1C@

Operating

characteristics

(See note 1.)

Operating distance OFF→ON 5 mm min.

Operating distance ON→OFF 15 mm max.

Differential travel (max.) 20% of operating distance

Influence of temperature (max.) ±20% of operating distance at 23°C, within temperature range of −10 to 55°C

Ambient operating temperature −10 to 55°C (no icing or condensation)

Ambient operating humidity 25% to 85%

Insulation resistance (between charged parts and case) 50 MΩmax. (at 500 VDC)

Dielectric strength (between charged parts and case) 1,000 VAC for 1 min

Vibration resistance 10 to 55 to 10 Hz (single amplitude: 0.75 mm, double amplitude: 1.5 mm)

Shock resistance 300 m/s2min.

Degree of protection IP67

Material PBT resin

Mounting method M4 screws

Terminal screw tightening torque 1 N·m

Power consumption 0.6 W max.

Auxiliary outputs (See note 2.) 24 VDC, 10 mA (PNP open-collector outputs)

LED indicators Actuator not detected (red); actuator detected (yellow)

Connection cables 2 m, 5 m

Number of connectable switches (See note 3.) 30 max. (wiring length: 100 m max.)

Weight Switch: approx. 145 g, actuator: approx. 20 g (D40A-1C2)