D4BL

5

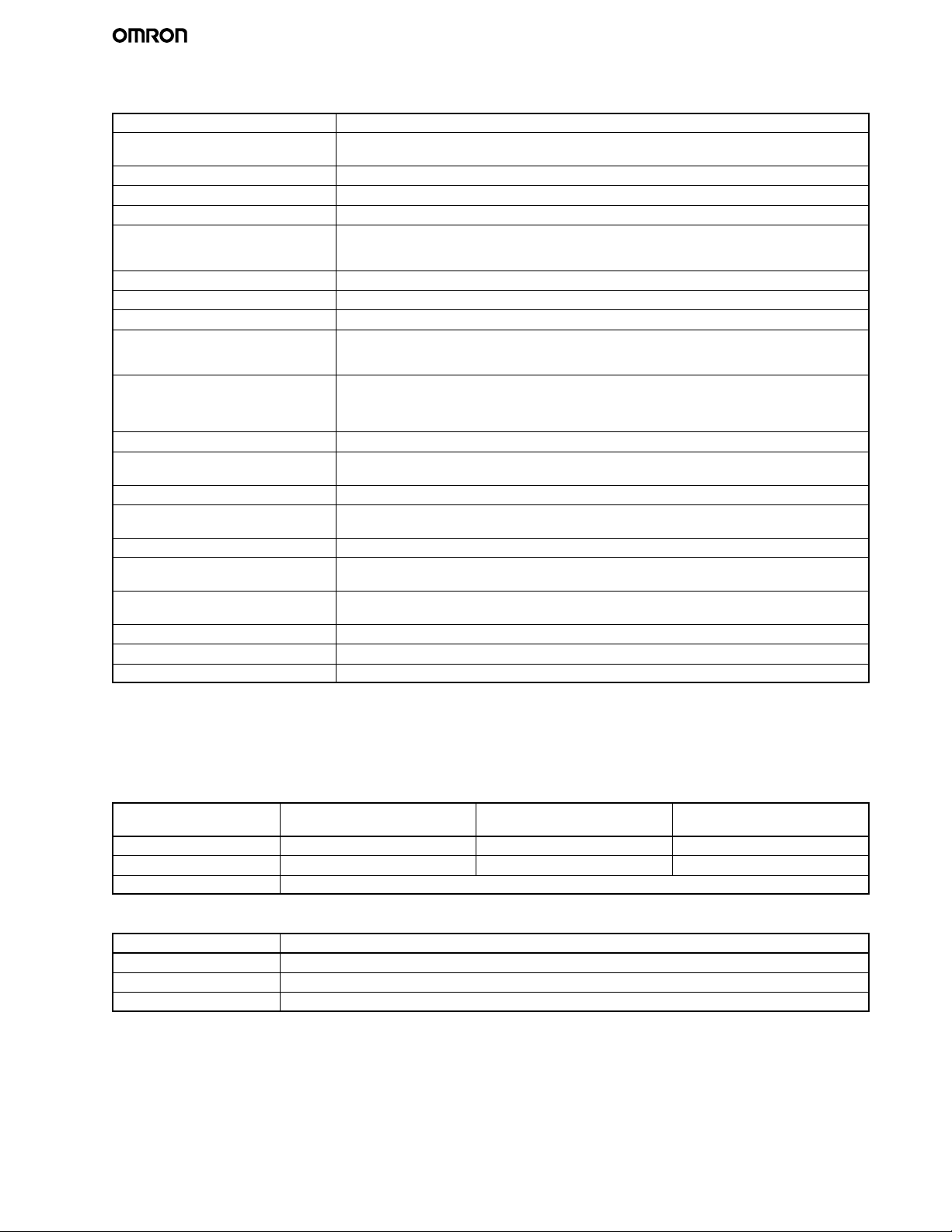

JCHARACTERISTICS

Degree of protection IP67 (See note 2.)

Life expectancy (See note 3.) Mechanical: 1,000,000 operations min.

Electrical: 500,000 operations min.

Operating speed 0.05 to 0.5 m/s

Operating frequency 30 operations/min max.

Rated frequency 50/60 Hz

Operating characteristics Positive opening force: 19.61 N min. (EN60947-5-1)

Positive opening stroke: 20 mm min. (EN60947-5-1)

All stroke:23 mm min.

Locked resistive pulling force 700 N min. (GS-ET-19)

Insulation resistance 100 MΩmin. (at 500 VDC)

Rated insulation voltage (Ui)300 VAC (EN60947-5-1)

Conventional enclosed thermal

current (Ithe) (rated continuous

current)

10 A (EN60947-5-1)

Dielectric strength (Uimp)Impulse dielectric strength (Uimp) 4 kV (EN60947-5-1) between terminals of different polarity,

between each terminal and ground, and between each terminal and non-current-carrying metal

part;

2.5 kV between solenoid and ground

Conditional short-circuit current 100 A (EN60947-5-1)

Operating environmental pollution

level Pollution degree 3 (EN60947-5-1)

Electric shock protection class Class I (with grounded terminal)

Counter electromotive voltage at

switching 1,500 V max. (EN60947-5-1)

Contact resistance 50 mΩmax. (initial value)

Vibration resistance Malfunction: 10 to 55 Hz, 0.35-mm single amplitude with an imposed acceleration of 50 m/s2

max. (IEC68-2-6)

Shock resistance Destruction: 1,000 m/s2min. (IEC68-2-27)

Malfunction: 300 m/s2min. (IEC68-2-27)

Ambient temperature Operating: --10°Cto55°C (with no icing)

Ambient humidity Operating: 95% max.

Weight Approx. 800 g

Note: 1. The values provided in the above table are the initial values.

2. Although the switch box does not allow the penetration of dust, oil or water, avoid as much as possible the penetration of dust,

oil, or water into the head’s Operation Key insertion slot.

3. The life expectancy is for an ambient temperature of 5°Cto35°C and ambient humidity of 40% to 70%. For further conditions,

consult your OMRON sales representative.

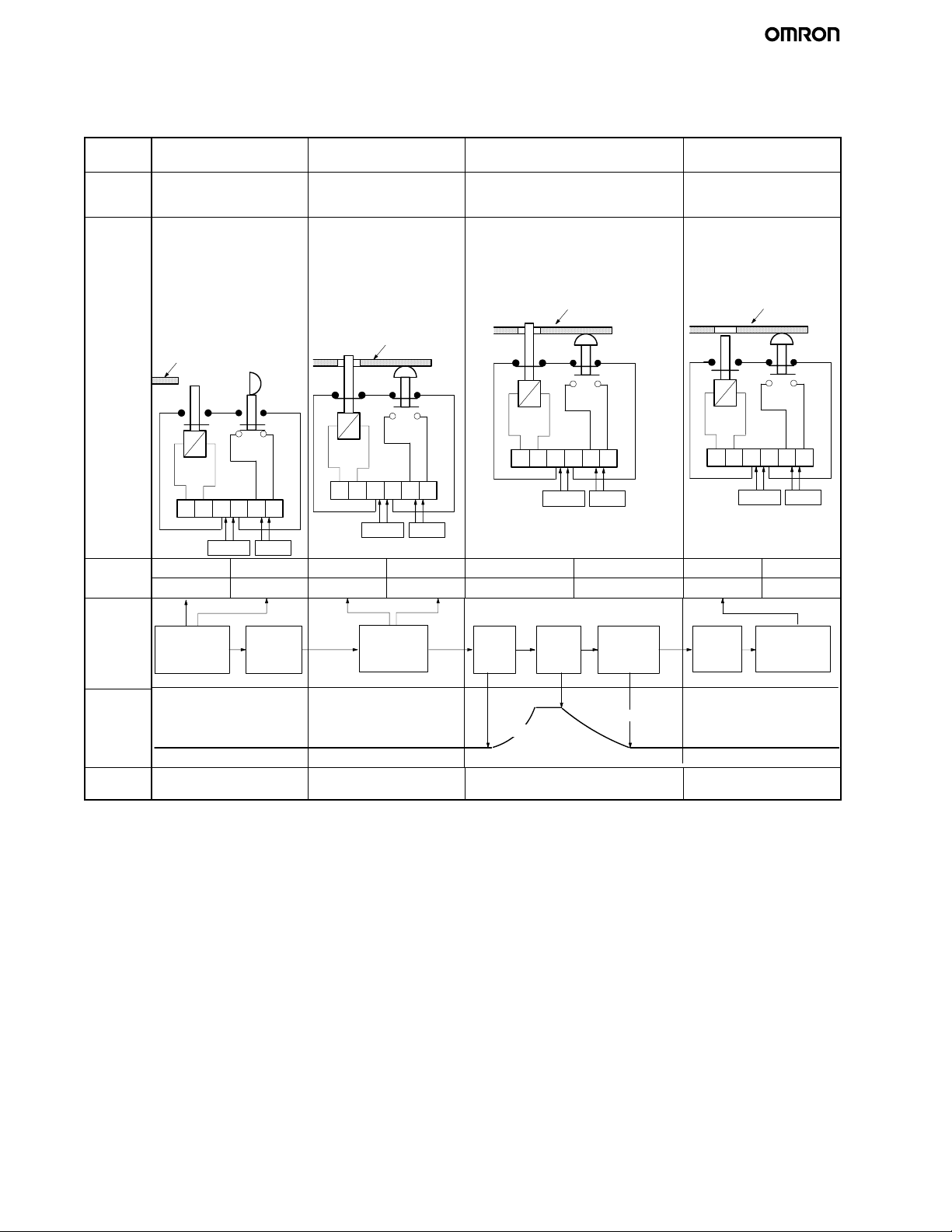

Solenoid Coil Characteristics

Item 24-VDC Mechanical lock models 110-VAC Mechanical lock

models 24-VAC Solenoid lock models

Rated operating voltage 24 VDC +10%/--15% (100% ED) 110 VAC ±10% (50/60 Hz) 24 VDC +10%/--15% (100% ED)

Current consumption Approx. 300 mA Approx. 98 mA Approx. 300 mA

Insulation class Class F (130°Corless)

Indicator Characteristics

Item LED

Rated voltage 10 to 115 VAC/VDC

Current consumption Approx. 1 mA

Indicator color (LED) Orange, green