CAT24C01, CAT24C02, CAT24C04, CAT24C08, CAT24C16

http://onsemi.com

4

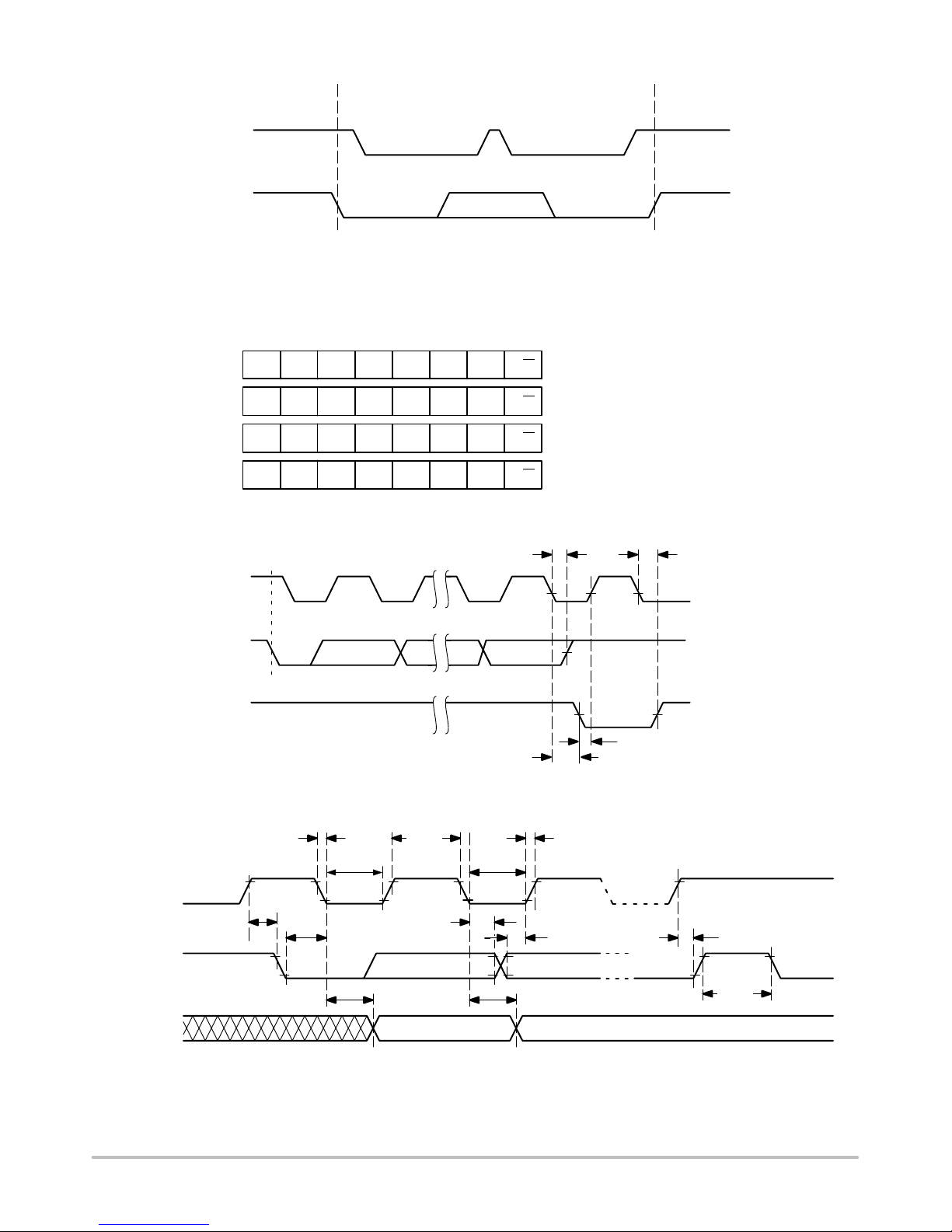

Table 7. A.C. TEST CONDITIONS

Input Drive Levels 0.2 x VCC to 0.8 x VCC

Input Rise and Fall Time v50 ns

Input Reference Levels 0.3 x VCC, 0.7 x VCC

Output Reference Level 0.5 x VCC

Output Test Load Current Source IOL = 3 mA (VCC w2.5 V); IOL = 1 mA (VCC < 2.5 V); CL= 100 pF

Power−On Reset (POR)

Each CAT24Cxx* incorporates Power−On Reset (POR)

circuitry which protects the internal logic against powering

up in the wrong state.

A CAT24Cxx device will power up into Standby mode

after VCC exceeds the POR trigger level and will power

down into Reset mode when VCC drops below the POR

trigger level. This bi−directional POR feature protects the

device against ‘brown−out’ failure following a temporary

loss of power.

*For common features, the CAT24C01/02/04/08/16 will be

referred to as CAT24Cxx.

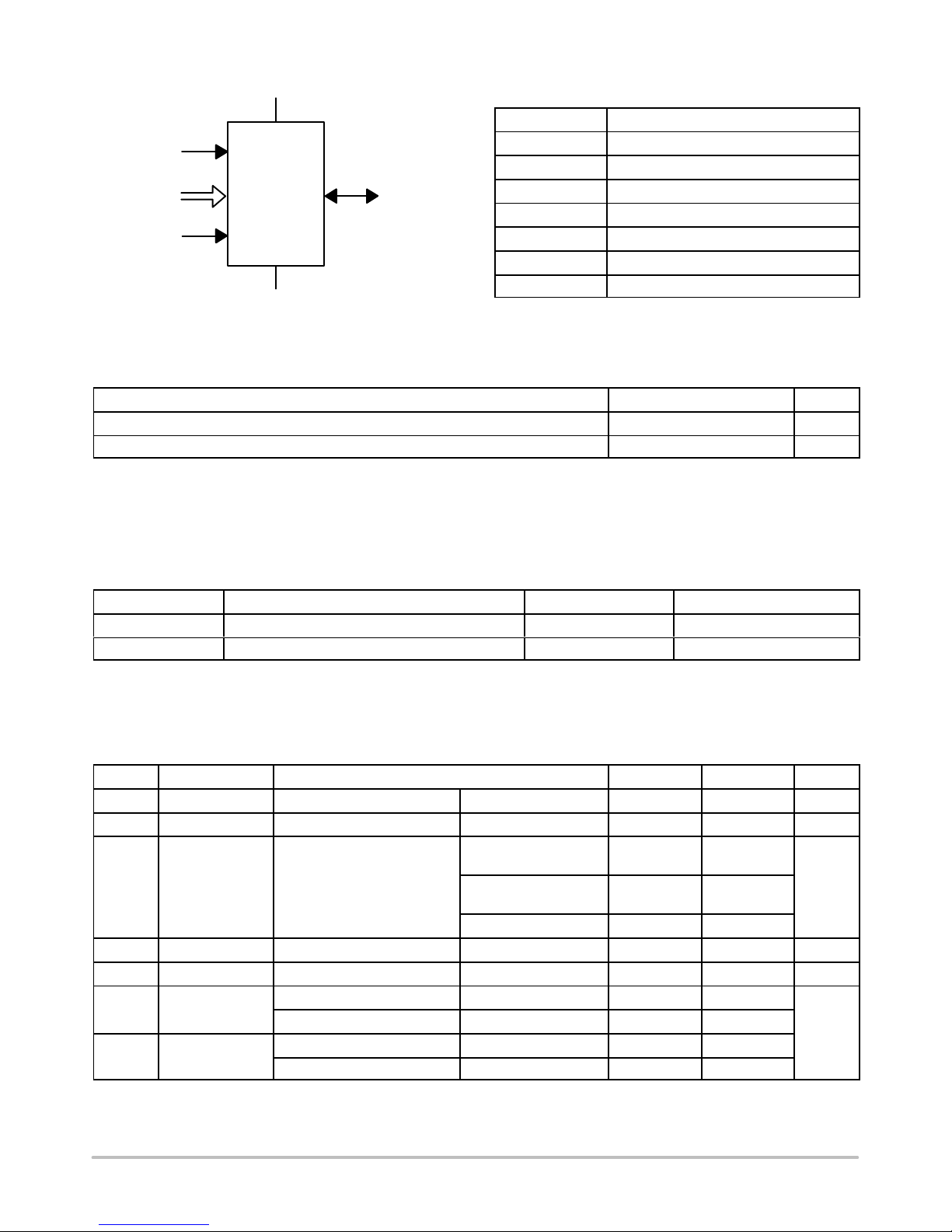

Pin Description

SCL: The Serial Clock input pin accepts the Serial Clock

generated by the Master.

SDA: The Serial Data I/O pin receives input data and

transmits data stored in EEPROM. In transmit mode, this pin

is open drain. Data is acquired on the positive edge, and is

delivered on the negative edge of SCL.

A0, A1 and A2: The Address inputs set the device address

when cascading multiple devices. When not driven, these

pins are pulled LOW internally.

WP: The Write Protect input pin inhibits all write

operations, when pulled HIGH. When not driven, this pin is

pulled LOW internally.

Functional Description

The CAT24Cxx supports the Inter−Integrated Circuit

(I2C) Bus data transmission protocol, which defines a device

that sends data to the bus as a transmitter and a device

receiving data as a receiver. Data flow is controlled by a

Master device, which generates the serial clock and all

START and STOP conditions. The CAT24Cxx acts as a

Slave device. Master and Slave alternate as either

transmitter or receiver.

I2C Bus Protocol

The I2C bus consists of two ‘wires’, SCL and SDA. The

two wires are connected to the VCC supply via pull−up

resistors. Master and Slave devices connect to the 2−wire

bus via their respective SCL and SDA pins. The transmitting

device pulls down the SDA line to ‘transmit’ a ‘0’ and

releases it to ‘transmit’ a ‘1’.

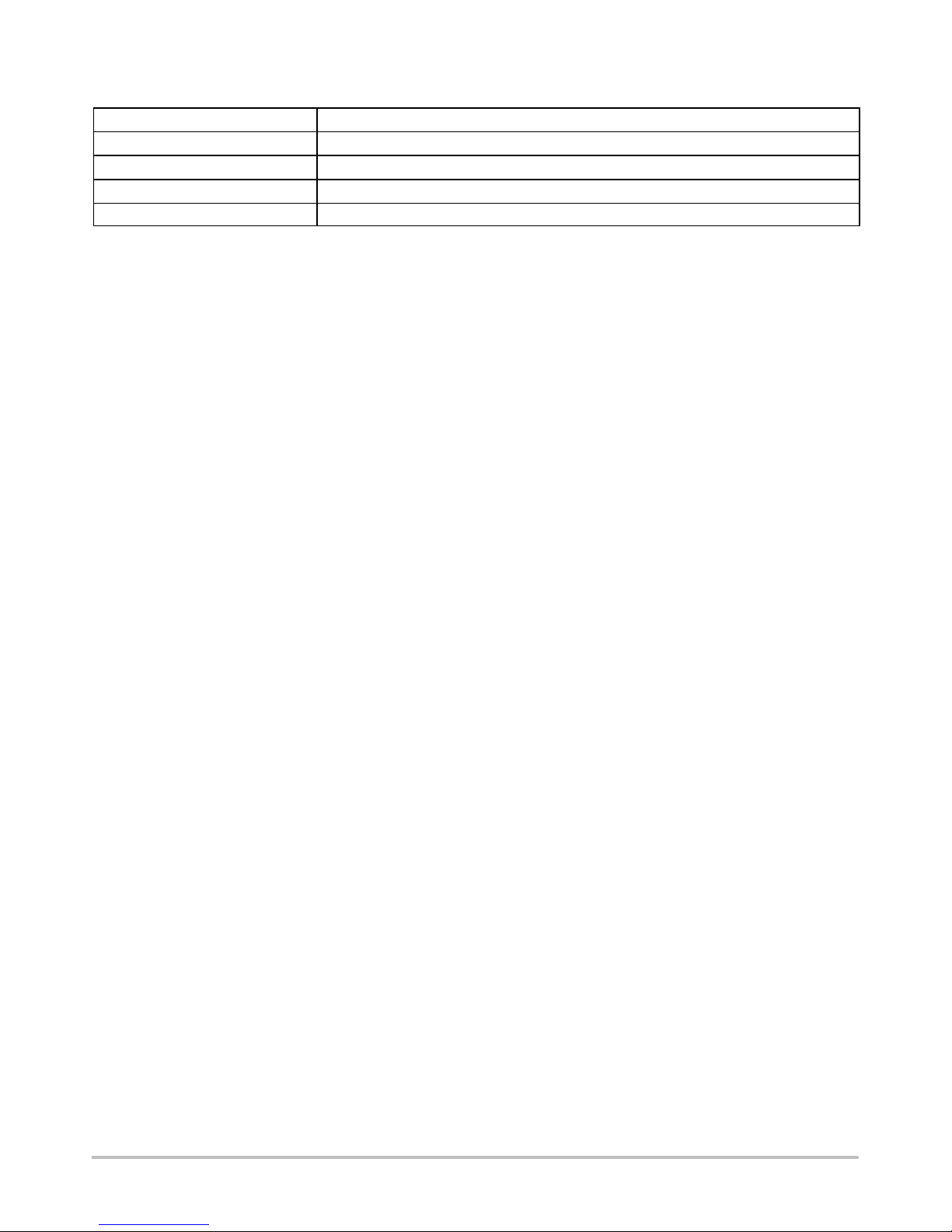

Data transfer may be initiated only when the bus is not

busy (see AC Characteristics).

During data transfer, the SDA line must remain stable

while the SCL line is high. An SDA transition while SCL is

high will be interpreted as a START or STOP condition

(Figure 2). The START condition precedes all commands. It

consists of a HIGH to LOW transition on SDA while SCL

is HIGH. The START acts as a ‘wake−up’ call to all

receivers. Absent a START, a Slave will not respond to

commands. The STOP condition completes all commands.

It consists of a LOW to HIGH transition on SDA while SCL

is HIGH.

NOTE: The I/O pins of CAT24Cxx do not obstruct the SCL

and SDA lines if the VCC supply is switched off. During

power−up,the SCL and SDA pins (connected with pull−up

resistors to VCC) will follow the VCC monotonically from

VSS (0 V) to nominal VCC value, regardless of pull−up

resistor value. The delta between the VCC and the

instantaneous voltage levels during power ramping will be

determined by the relation between bus time constant

(determined by pull−up resistance and bus capacitance) and

actual VCC ramp rate.

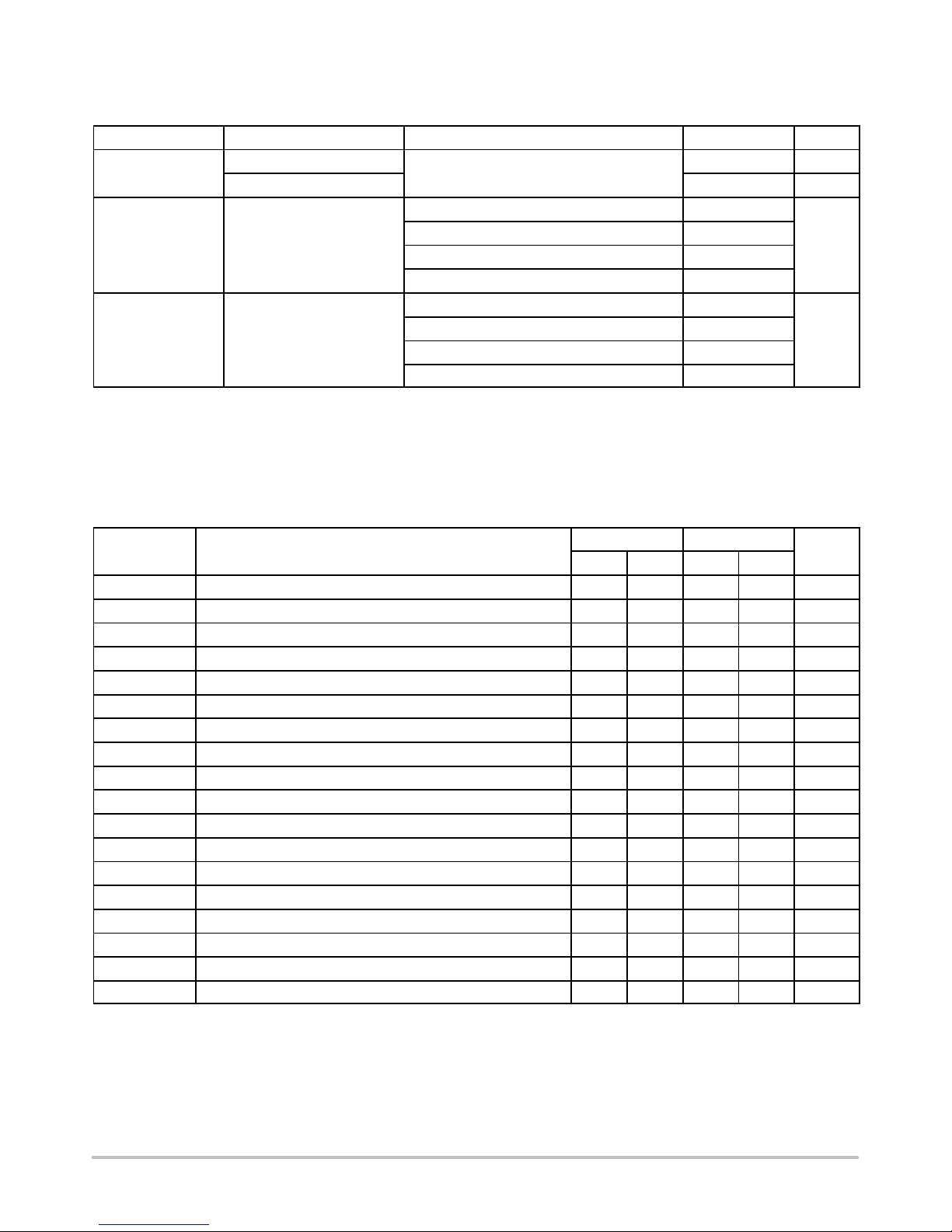

Device Addressing

The Master initiates data transfer by creating a START

condition on the bus. The Master then broadcasts an 8−bit

serial Slave address. For normal Read/Write operations, the

first 4 bits of the Slave address are fixed at 1010 (Ah). The

next 3 bits are used as programmable address bits when

cascading multiple devices and/or as internal address bits.

The last bit of the slave address, R/W, specifies whether a

Read (1) or Write (0) operation is to be performed. The 3

address space extension bits are assigned as illustrated in

Figure 3. A2, A1and A0must match the state of the external

address pins, and a10, a9and a8are internal address bits.

Acknowledge

After processing the Slave address, the Slave responds

with an acknowledge (ACK) by pulling down the SDA line

during the 9th clock cycle (Figure 4). The Slave will also

acknowledge the address byte and every data byte presented

in Write mode. In Read mode the Slave shifts out a data byte,

and then releases the SDA line during the 9th clock cycle. As

long as the Master acknowledges the data, the Slave will

continue transmitting. The Master terminates the session by

not acknowledging the last data byte (NoACK) and by

issuing a STOP condition. Bus timing is illustrated in

Figure 5.