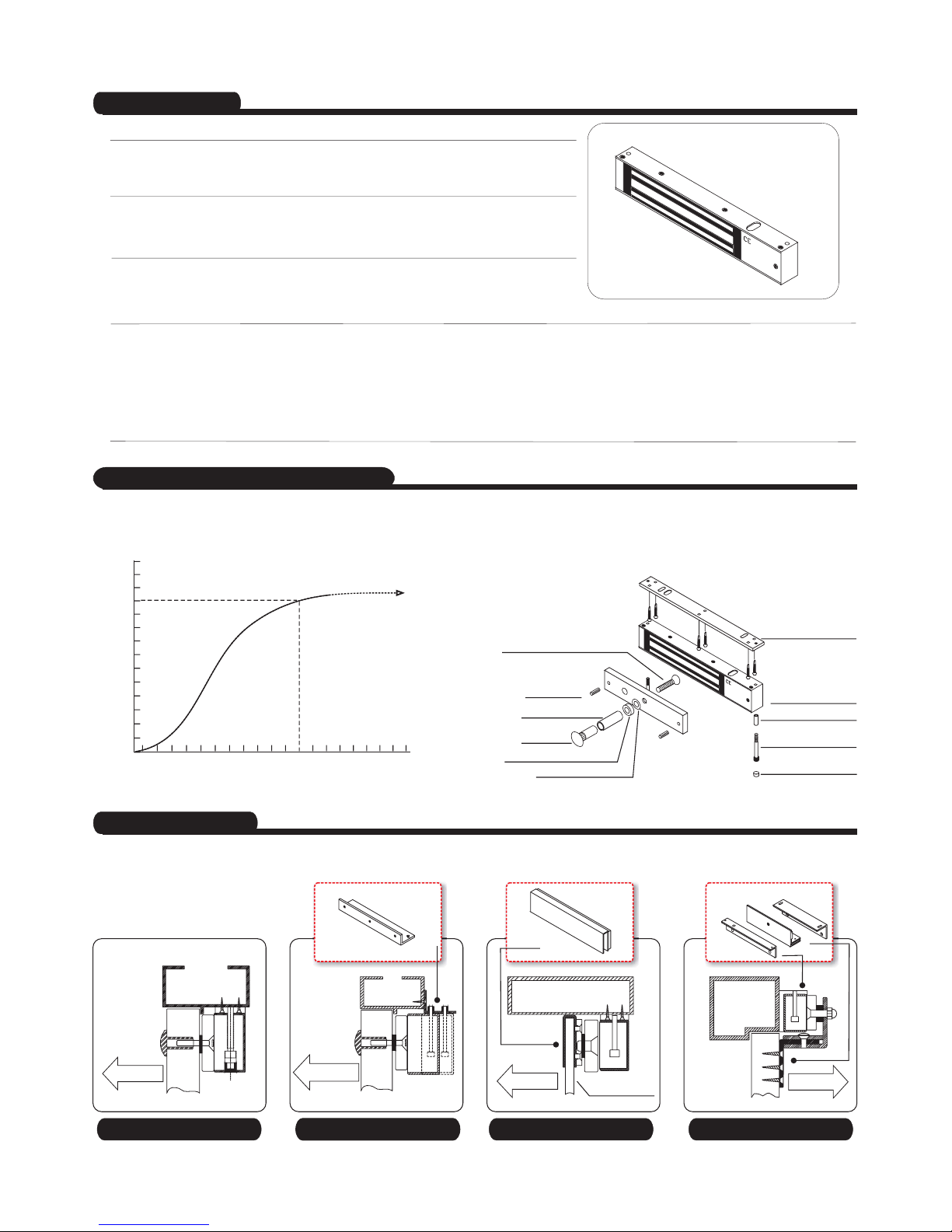

" L " Bracket

(Option)

Out-swinging

7

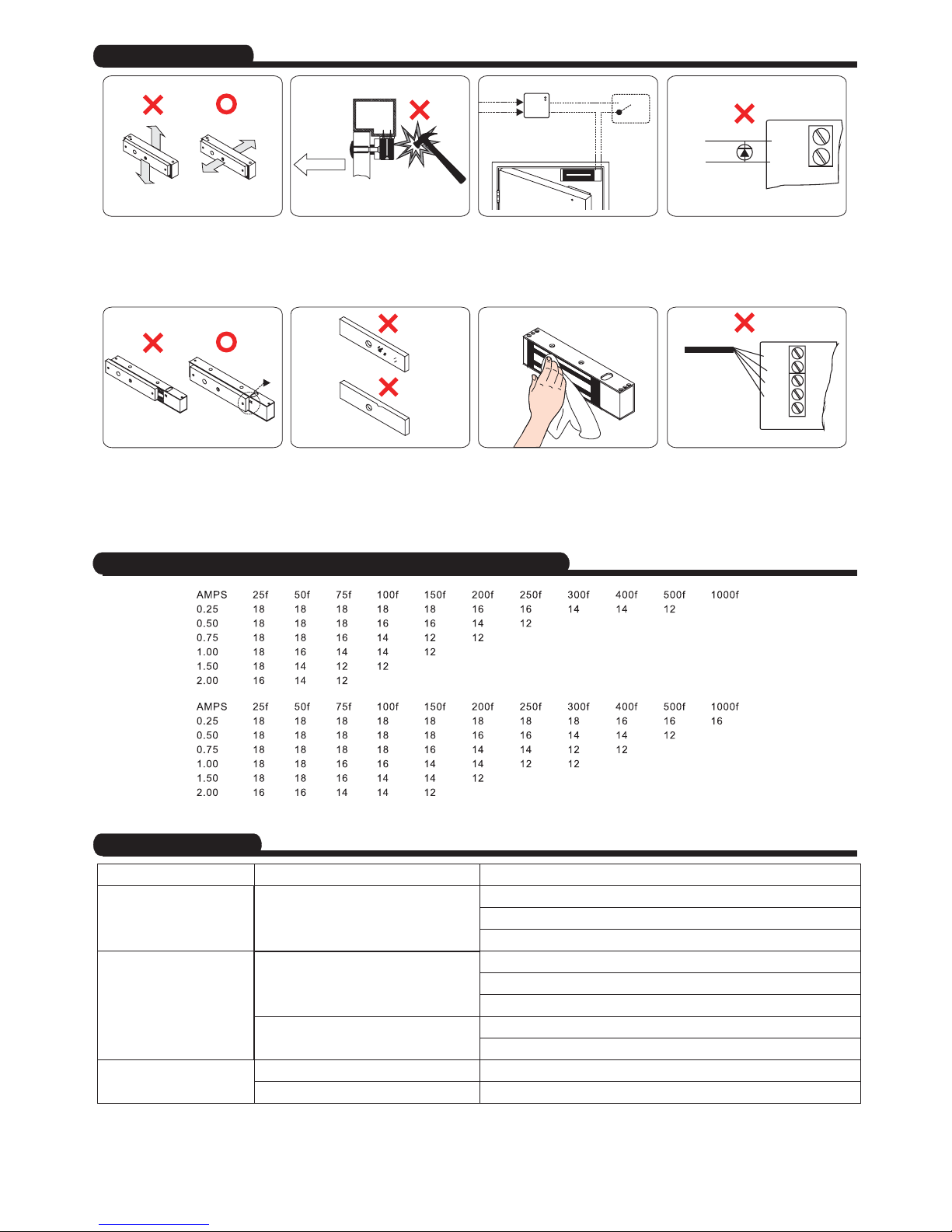

Put one rubber washer between

two washers, and place them over

the armature screw between the

armature plate and the door.

9

Screw the two self-tapping screws

in the slotted holes of the mounting

plate and adjust the position of the

mounting plate so that it and the

armature plate from a 90-degree

angle.

Template

1

Fold the mounting template along

the dotted line to a 90-degree

angle.

door

Out-swinging Template

2

Close the door, find a mounting

location on the door frame near the

upper free-moving corner of the door,

as close to the corner of the door

frame as possible.

3

Place the template against the door

and frame. Drill two holes in the frame

and three holes in door as indicated

on the template.

8

This will allow the armature plate to

pivot slightly around the armature

screw in order to compensate for

door misalignment.

Rubber Washer

Regular Installation

4

Drill two holes in the frame and

three holes in the door as

indicated on the template.

6.8mm for M8-1.25 thread

16mm 8mm 12.7mm 8mm

Drill an 8 mm hole through

door, from sexnut bolt side

only, enlarge the 8mm hole

to 16mm.

Micro EM-locks (300 LBS) maximum thickness of door is 44 mm.

Mini EM-locks (600 LBS) maximum thickness of door is 50 mm.

Midi EM-locks (800 LBS) maximum thickness of door is 48 mm.

Standard EM-locks (1200 LBS) maximum thickness of door is 46 mm.

Recommendation:

Drill an 8 mm hole thru

door from sexnut bolt

side of door, drill 12.7mm

hole, 36mm in depth.

Drill an 6.8 mm dia.

Hole and tap for

M8x12.5 thread.

Hollow Metal Door Solid Door Reinforced Door

36mm

5

Mounting the armature plate to

the door . Actual installation

varies according to door style.

Armature Plate

10

Once the position is correct, use

the screws to permanently mount

the mounting plate, And drill the

cable access hole.

Cable

12

Connect the power lead, and test

the unit.

Holding Force

Power

11

Use the Allen wrench to screw the

Fixing screws and Brass Sleeves

through the bottom of the

electromagnet into the mounting

plate.

Allen wrench

Finish

Insert the anti-tamper caps into the

mounting screw access holes. This

should be the last step, as once the

tamper caps are in place, they will

be difficult to remove.

With L bracket for narrow door frames With U bracket for frameless glass doors

Universal glass door kits are

compatible with lock models,

except 1200 lbs serial.

Out-swinging (Option)

UBK Bracket

UBK-008 for 8mm of glass door

UBK-010 for 10mm of glass door

UBK-012 for 12mm of glass door

UBK-014 for 14mm of glass door

4-2

6

Make sure the Guide Pins are in

the two guide pin holes.

Guide Pins

Installation Steps

All Rights Reserved.

PublishPMUAMEM Ver. E :2007.01.24

L bracket is used as an extension

on narrow door frames to provide

adequate mounting surface.