15

15

Instructions

10. Insert the threaded rod (3) as an axle into the axle carrier

(f). Add wheels (15) to both sides of the axle (j) as de-

scribed in step 7.

Drill a ø4mm hole

11. Drill a ø4mm hole through the centre of part (i) in order

to feed the cables through.

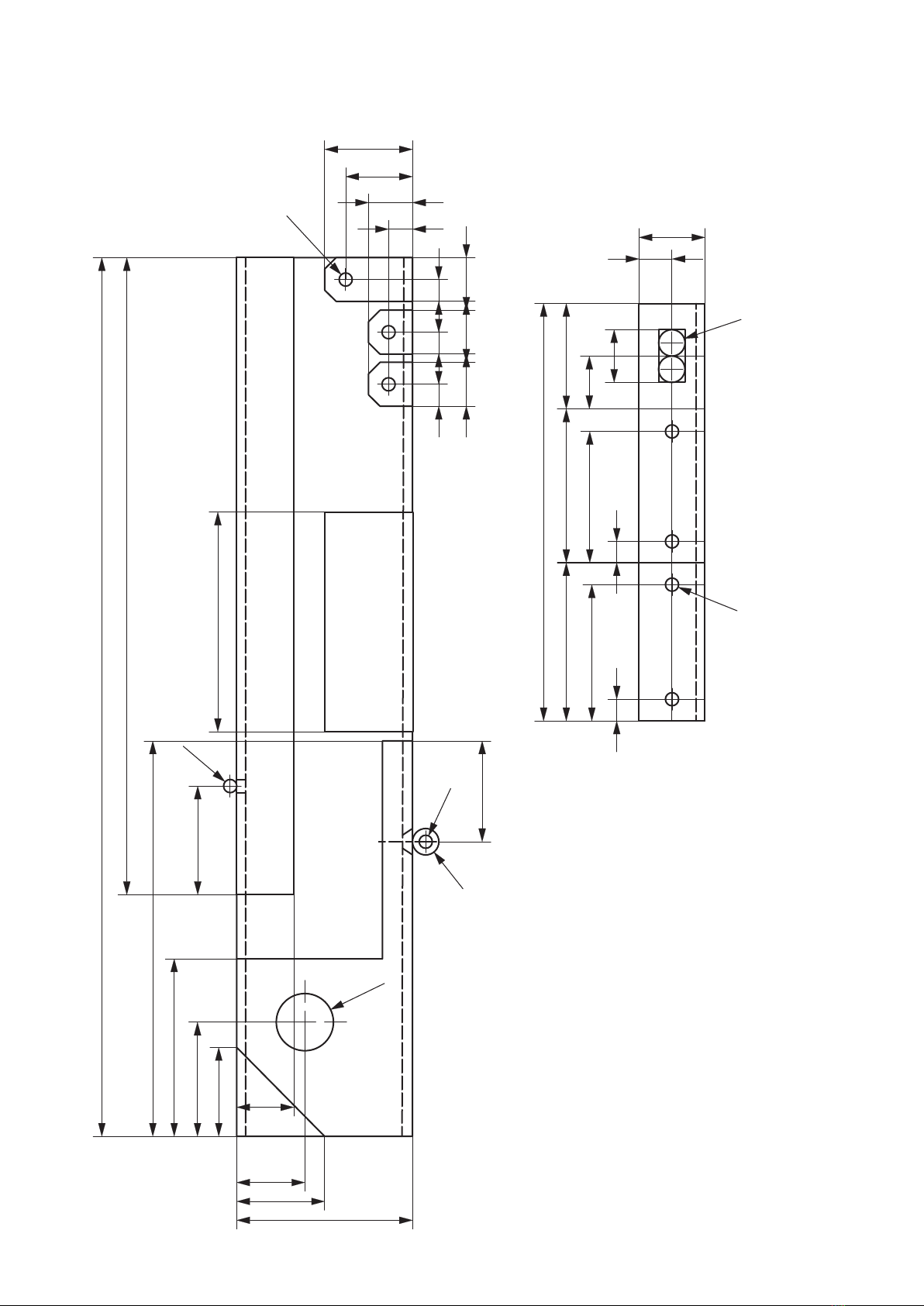

Cabling:

Wiring diagram:

12. Solder the resistor (12) to the outer switch connec-

tor (11). Strip the insulation from the red battery

clip cable (10), tin it, feed it upwards through the

drill hole in part (h) and solder it to the centre

switch connector (11). Strip the insulation from the

black battery clip cable, tin it and feed it upwards

through the drill hole in part (h). Solder the anodes

(long leg) of the red LEDs together. Then solder the

two cathodes (short leg) together. Do the same

with the two yellow LEDs. Cut o approx. 180mm

wire (red, 8) strip the insulation from both sides

and tin. Feed one end upwards through the drill

hole in part (h). Connect the other end to the two

anodes from the red LEDs (13). Cut o approx.

150mm wire (red, 8) strip the insulation from both

sides and tin. Again feed one end through the drill

hole, twist it with the end of the 180mm wire and

solder to the resistor (12). Connect the other end to

the anodes of the yellow LEDs (14).

Cut o approx. 180mm of black wire (9) strip the

insulation and tin. Feed one end upwards through

the drill hole in part (h) and twist it with the end of

the black cable from the battery clip (10). Solder

the other end to the two cathodes from the red

LED (13). Cut o approx. 150mm of black wire (9),

strip the insulation, tin, feed upwards through the

drilled hole, twist s well with the black cable from

the battery clip (10) and solder the three black cab-

les together. Connect the other end to the catho-

des from the yellow LEDs (14). Connect the battery

to the battery clip and insert the battery into its

compartment (part c).

Note: Do not touch any PVC parts with the solde-

ring iron when soldering!

LED red LED

yellow

Resistance 180 ohm

red black

180mm

black

150mm

red

180mm

red

150mm