Page 6 Confidential Limited Distribution

•Step 20 ............................................................................................50

•Step 21 ............................................................................................50

•Step 22 ............................................................................................51

SUMA Flash Testing.....................................................................................52

•Step 1 ..............................................................................................52

•Step 2 ..............................................................................................52

•Step 3 ..............................................................................................53

•Step 4 ..............................................................................................53

6. TDR8 Relay Module..........................................................................................54

7. TD100 Power Supply Units................................................................................55

TD24PSU .....................................................................................................55

•Battery Backup (Optional)................................................................56

TD24PSU Test Procedure ............................................................................59

•Step 1 ..............................................................................................59

•Step 2 ..............................................................................................59

•Step 3 ..............................................................................................60

•Step 4 (Optional)..............................................................................61

TD48PSU .....................................................................................................64

TD48PSU Test Procedure ............................................................................66

•Step 1 ..............................................................................................66

•Step 2 ..............................................................................................67

•Step 3 ..............................................................................................67

8. Intrusion Testing................................................................................................69

Basic Tests...................................................................................................69

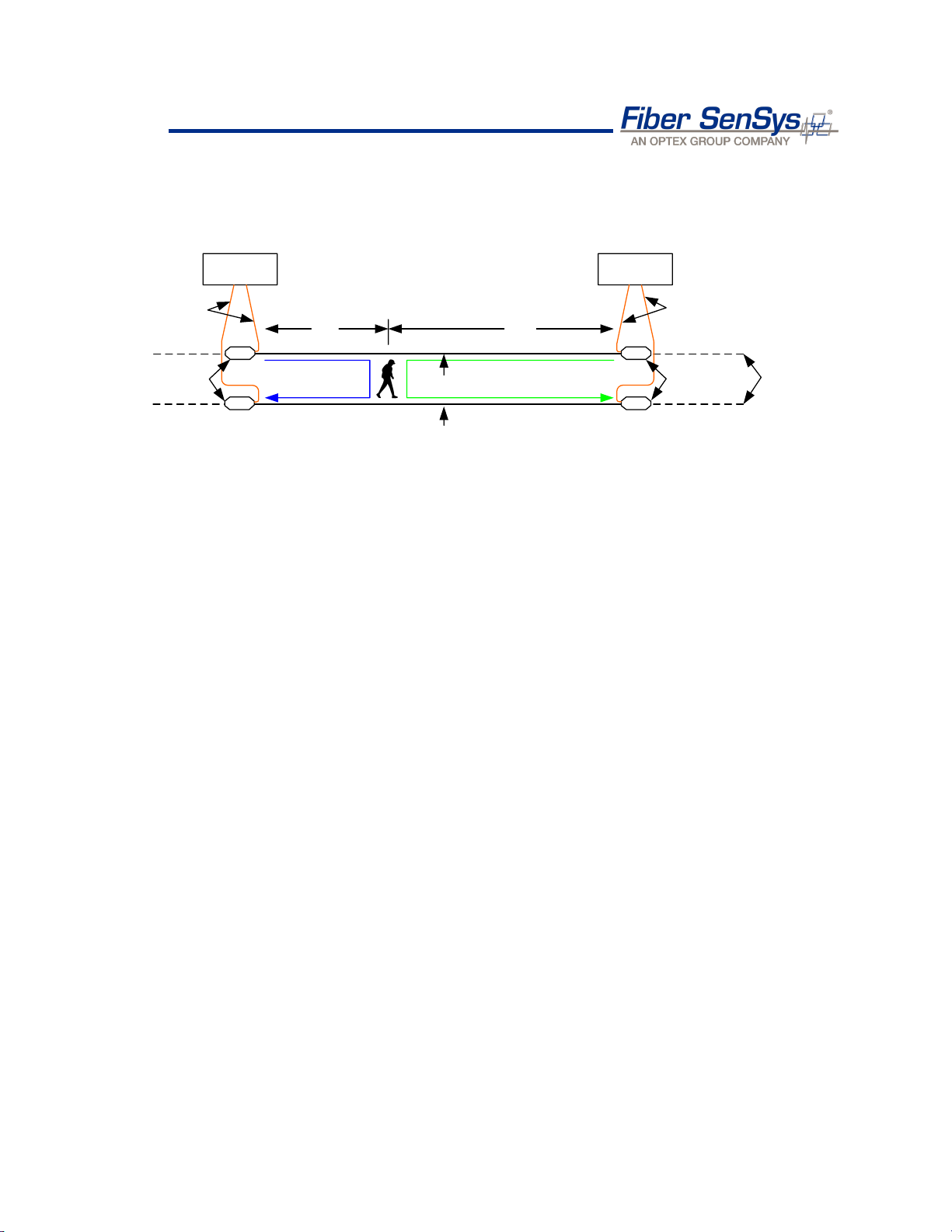

•Walk Testing:...................................................................................69

•Run Testing:.....................................................................................69

•Basic Testing Reference Table: .......................................................69

Advanced Tests............................................................................................70

•Crawl Testing:..................................................................................70

•Crawl Testing Reference Table:.......................................................71

•Run and Jump Testing:....................................................................71

•Run and Jump Testing Reference Table:.........................................71

9. Maintenance, Troubleshooting, and Repair.......................................................73

Maintenance.................................................................................................73

•Visual Inspection Every 90 Days:..................................................73

•TD100 Processor Status Check Every 180 Days: .........................73

•Performance Testing Every 180 Days:..........................................74

•Maintenance and Test Log:..............................................................74

Troubleshooting............................................................................................75

•Cut/Broken Sensor Cable:................................................................75

•Password Reset:..............................................................................77

•TD100 LED Status Table: ................................................................78

•Elevated Nuisance Alarms:..............................................................78