CONTENTS

1. DISCLAIMER........................................................................1-1

2. LIMITED WARRANTY CONDITIONS .............................................2-1

3. WARNINGS .........................................................................3-1

4. SYMBOLS ...........................................................................4-1

5. GENERAL INFORMATION.........................................................5-1

5.1 THEORY OF OPERATION.................................................................5-1

5.2 DESCRIPTION OF THE SYSTEM..........................................................5-1

5.3 TECHNICAL SPECIFICATIONS............................................................5-2

5.4 EMC TABLES ..............................................................................5-3

5.4.1 ELECTROMAGNETIC EMISSIONS........................................................................... 5-3

5.4.2 ELECTROMAGNETIC IMMUNITY ........................................................................... 5-4

5.4.3 RECOMMENDED SEPARATION DISTANCES ............................................................... 5-5

5.5 WIRING DIAGRAMS.......................................................................5-6

6. INSTALLATION AND MAINTENANCE............................................6-1

6.1 INTRODUCTION...........................................................................6-1

6.2OPENING THE PACKAGE AND INITIAL INSPECTION ..................................6-1

6.3 INSTALLATION PROCEDURE.............................................................6-1

7. OPERATION OF THE APPARATUS ..............................................7-1

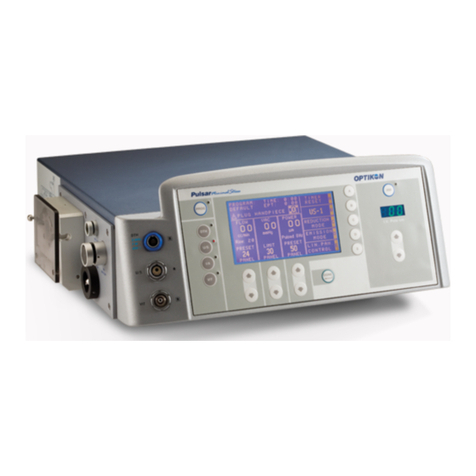

7.1 DESCRIPTION OF THE APPARATUS.....................................................7-1

7.1.1 DISPLAY ...................................................................................................... 7-1

7.1.2 SYSTEM STATES............................................................................................. 7-1

7.1.3 INITIAL TEST OF THE SYSTEM ............................................................................ 7-1

7.1.4 STANDARD OPERATION .................................................................................... 7-1

7.1.5 TEMPERATURE CONTROL.................................................................................. 7-1

7.1.6 APPLICATION TIME CONTROL............................................................................. 7-2

7.1.7 APPLICATION TIME AND APPLIED TEMPERATURE CONTROL......................................... 7-2

7.2 CONFIGURATION OF THE UNIT.........................................................7-3

7.3 USER INTERFACE.........................................................................7-5

7.4 SOUND MESSAGES........................................................................7-6

8. USER INTERFACE..................................................................8-1

8.1 LANGUAGE SELECTION..................................................................8-1

8.2 STANDARD OPERATION..................................................................8-1

8.3 APPLICATION TIME CONTROL ..........................................................8-2

8.4 APPLICATION TEMPERATURE CONTROL...............................................8-3

8.5 SYSTEM TEST .............................................................................8-5

8.6 SHUTDOWN PROCEDURE................................................................8-6

9. CLEANING, STERILIZATION AND MAINTANENCE.............................9-1

9.1 CLEANING.................................................................................9-1

9.1.1 UNIT .......................................................................................................... 9-1

9.1.2 ACCESSORIES................................................................................................ 9-1

9.2 STERILIZATION ...........................................................................9-2

9.2.1 UNIT .......................................................................................................... 9-2

9.2.2 CRYOSURGICAL PROBES................................................................................... 9-2

9.3 MAINTENANCE............................................................................9-2

9.3.1 UNIT .......................................................................................................... 9-2

9.3.2 ACCESSORIES................................................................................................ 9-2

10. TROUBLESHOOTING GUIDE ................................................... 10-1

10.1 WARNINGS AND ERROR MESSAGES................................................... 10-1

10.2 MISCELLANEOUS PROBLEMS .......................................................... 10-2

11. ACCESSORIES ....................................................................11-1