OPTIMUM

MASCHINEN - GERMANY

Version 1.0.2 dated 2016-1-28Page 2 Original operating instructions

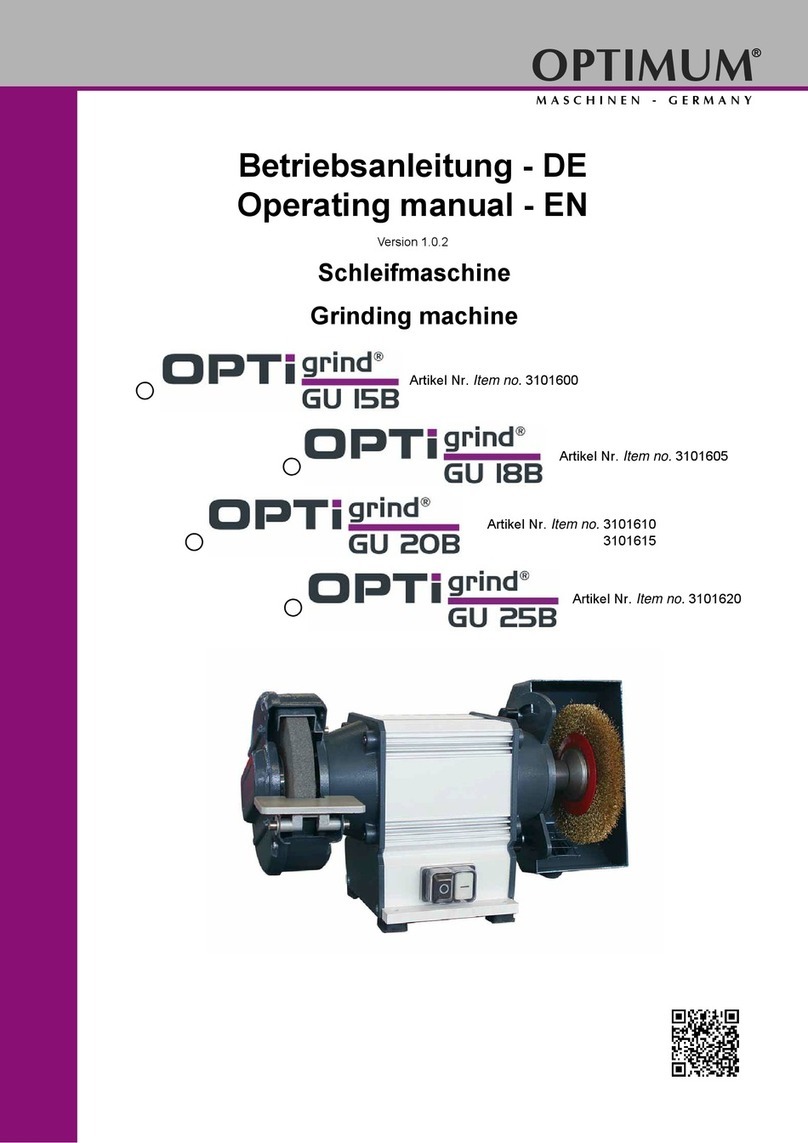

GU15 │GU18 │GU20 │GU20S │GU20P│GU25│GU25S│GU25PGB

Table of contents

1 Safety

1.1 Safety instructions (warning notes)...........................................................................................................4

1.1.1 Classification of hazards...........................................................................................................................4

1.1.2 Other pictograms ......................................................................................................................................5

1.2 Intended use .............................................................................................................................................5

1.3 Reasonably foreseeable misuse...............................................................................................................6

1.3.1 Avoiding misuse........................................................................................................................................6

1.4 Possible dangers caused by the grinding machine ..................................................................................6

1.5 Qualification of personnel .........................................................................................................................7

1.5.1 Target group .............................................................................................................................................7

1.6 Operator positions ....................................................................................................................................8

1.7 Safety measures during operation............................................................................................................8

1.8 Safety devices ..........................................................................................................................................8

1.8.1 Spark-guard and support surface .............................................................................................................8

1.9 Safety check .............................................................................................................................................9

1.10 Personal protective equipment .................................................................................................................9

1.11 For your own safety during operation .......................................................................................................9

1.12 Disconnecting and securing the grinding machine .................................................................................10

1.13 Emissions ...............................................................................................................................................10

1.14 Basic information on grinding wheels .....................................................................................................10

2 Technical data

3 Unpacking and Connecting

3.1 Scope of delivery ....................................................................................................................................11

3.2 Storage ...................................................................................................................................................11

3.3 Installation and assembly .......................................................................................................................12

3.3.1 Requirements regarding the installation site...........................................................................................12

3.4 First commissioning ................................................................................................................................12

3.5 Dimensions .............................................................................................................................................13

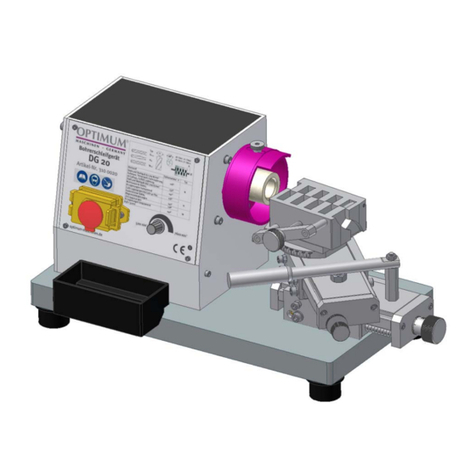

3.6 Overview GU20S | GU25S .....................................................................................................................16

3.7 First commissioning ................................................................................................................................17

3.7.1 Power supply ..........................................................................................................................................18

3.8 Operation ................................................................................................................................................18

4 Maintenance

4.1 Safety......................................................................................................................................................19

4.1.1 Preparation .............................................................................................................................................19

4.2 Inspection and maintenance...................................................................................................................19

4.3 Replacing a grinding wheel.....................................................................................................................20

4.4 Replacing a polishing wheel ...................................................................................................................20

4.5 Replacing the sanding belt .....................................................................................................................21

4.6 Repair .....................................................................................................................................................21

5 Appendix

5.1 Copyright ................................................................................................................................................22

5.2 Liability claims for defects / warranty ......................................................................................................22

5.3 Advice for disposal / options of reuse: ....................................................................................................23

5.3.1 Decommissioning ...................................................................................................................................23

5.3.2 Disposal of new device packaging..........................................................................................................23

5.3.3 Disposal of electrical and electronic components...................................................................................24

5.4 Disposal via municipal collection facilities ..............................................................................................24

5.5 Product follow-up ....................................................................................................................................24

5.6 Change information manual....................................................................................................................24