2

Repair, disassembly, and modication

yDo not disassemble or modify the cylinder. Doing so may result in injury.

Refer all such internal inspections and repairs to the Oriental Motor sales

oce from which you purchased the cylinder.

General

yDo not use the cylinder beyond its specications. Doing so may result in

injury or damage to equipment.

yDo not touch the cylinder during operation or immediately after stopping.

The surface is hot, and this may cause a skin burn(s).

Transportation

yDo not carry the cylinder by holding the ball screw, lead wire, or cable of

the cylinder. Doing so may result in injury.

Installation

yDo not place combustibles around the cylinder. Doing so may result in re

or a skin burn(s).

yDo not leave anything around the cylinder that would obstruct ventilation.

Doing so may result in damage to equipment.

yProvide a cover over the moving parts of the cylinder. Failure to do so may

result in injury.

Operation

yDo not touch the ball screw during operating. Doing so may result in injury.

yThe motor surface temperature may exceed 70 °C (158 °F)

even under normal operating conditions. If the operator

is allowed to approach the cylinder in operation, ax

a warning label shown in the gure on a conspicuous

position. Failure to do so may result in a skin burn(s).

Warning label

Precautions for use

This section covers restrictions and requirements the user should consider

when using the product.

•Thrust

Always operate the cylinder under a load not exceeding the thrust. Operating

the cylinder under a load beyond the thrust or allowing the ball screw to

remain locked may cause damage to the bearings (ball bearings) of the motor.

When using the cylinder in elevating applications, operate it under a load not

applying an external force and not exceeding the maximum transportable

mass in vertical direction.

•Permissible moment

Always operate the cylinder under a moment within the permissible value.

Continuing to operate the cylinder under a moment exceeding the

permissible value may cause malfunction or shorter service life of the cylinder.

•Do not hit the ball screw against an object to stop.

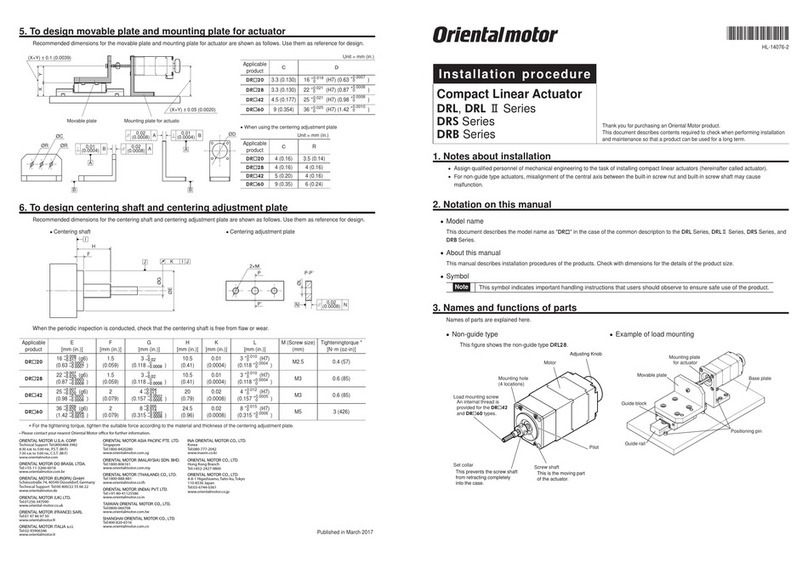

Hitting the operating ball screw against

an object to stop may cause damage

to the cylinder due to an impact. When

operating the cylinders, always provide

a stroke-end detection sensor or limit

sensor in order to prevent the ball screw

from hitting the stroke end or load. If it

is hit to stop, remove a load and return

the ball screw at the recommended

starting speed.

Installation example of limit sensor

T

he gure shows the non-guide type

ylinder.

C

Sensor

Model Lead (mm ) Recommended starting speed (mm/s)

DRLM20, DRLM28 1 0.2

DRLM42 2 0.4

8 1.6

DRLM60 4 0.8

•Do not move the position of the stopper.

The stopper is used to prevent the ball screw from retracting completely into

the motor. Moving the position of the stopper may cause damage to the ball

screw, resulting in cylinder malfunction or damage.

•Do not remove the joint from the ball screw.

Removing the joint causes the installation accuracy of the ball screw to

decrease, resulting in malfunction.

•Take measures to keep the moving part in position if the cylinder

is used in vertical drive such as elevating equipment.

The cylinder loses its holding force upon the occurrence of a power failure

or when the A.W.OFF (all windings o) input is turned ON. Take measures to

keep the moving part in position if the cylinder is used in vertical drive such

as elevating equipment.

•Motor surface temperature

Use the cylinder in conditions where the motor surface temperature dose not

exceed 90 °C (194 °F).

If the motor surface temperature exceeds 90 °C (194 °F) due to operating

conditions (ambient temperature, operating speed, operating duty, etc.), a

damaged motor coil or shorter service life of the bearing (ball bearing) may

result.

•Grease on ball screw

Grease on the ball screw may darken slightly within a short time after the

start of operation. This is not a problem if there is no abnormal noise (i.e., from

deection or interference). Wipe o the dirty grease with a soft cloth, and

apply new grease.

When grease on the ball screw has darkened after the initial operation,

the installation accuracy may be decreased. Refer to p.9 and check the

installation accuracy of the ball screw. When grease was darkened, refer to

p.14 and apply new grease.

•When conducting the insulation resistance measurement or

the dielectric strength test, be sure to separate the connection

between the cylinder and the driver.

Conducting the insulation resistance measurement or dielectric strength test

with the cylinder and driver connected may result in damage to the product.

•Non-guide type cylinder

Provide an anti-spin mechanism for the ball screw

The non-guide type cylinders cannot be operated without an anti-spin

mechanism for the ball screw because the ball screw rotates idly. Always

provide an anti-spin mechanism externally to the cylinder. In addition, make

sure the load installed to the ball screw is supported with a linear guide, etc.

Load to the ball screw

Applying a moment load to the ball screw may cause deterioration of the

ball screw. Support a load with a linear guide etc. and install the load in the

specied installation accuracy so that a moment load does not apply to the

ball screw. Refer to p.9 for the installation accuracy.

Installation accuracy

When using the non-guide type cylinders, always install within the specied

installation accuracy. Low accuracy of installation may result in a malfunction

or shorter service life of the cylinder. Refer to p.9 for the installation

accuracy.

When a carrier guide for load is provided

When a carrier guide for load is provided, always use the non-guide type

cylinders. (Do not use the guide type or table type cylinders.)

•Guide type cylinder, table type cylinder

The guide type and table type cylinders can receive a moment using the load

mounting holes in the joint. Use the cylinders under a moment within the

permissible value.