4

yUnauthorized reproduction or copying of all or part of this manual is prohibited.

yOriental Motor shall not be liable whatsoever for any problems relating to industrial

property rights arising from use of any information, circuit, equipment or device

provided or referenced in this manual.

yCharacteristics, specications and dimensions are subject to change without notice.

yWhile we make every eort to oer accurate information in the manual, we welcome

your input. Should you nd unclear descriptions, errors or omissions, please contact the

nearest oce.

yand are registered trademark or trademark of Oriental Motor

Co., Ltd., in Japan and other countries.

© Copyright ORIENTAL MOTOR CO., LTD. 2012

Published in February 2018

echnical Support Tel:(800)468-3982

A.M. to 5:00 P.M., P.S.T. (M-F)

A.M. to 5:00 P.M., C.S.T. (M-F)

.orientalmotor.com

Schiessstraße 44, 40549 Düsseldor

f, Germany

echnical Support Tel:00 800/22 55 66 22

.orientalmotor.de

el:01256-347090

.oriental-motor.co.uk

el:01 47 86 97 50

.orientalmotor.fr

el:02-93906346

.orientalmotor.it

el:+55-11-3266-6018

.orientalmotor.com.br

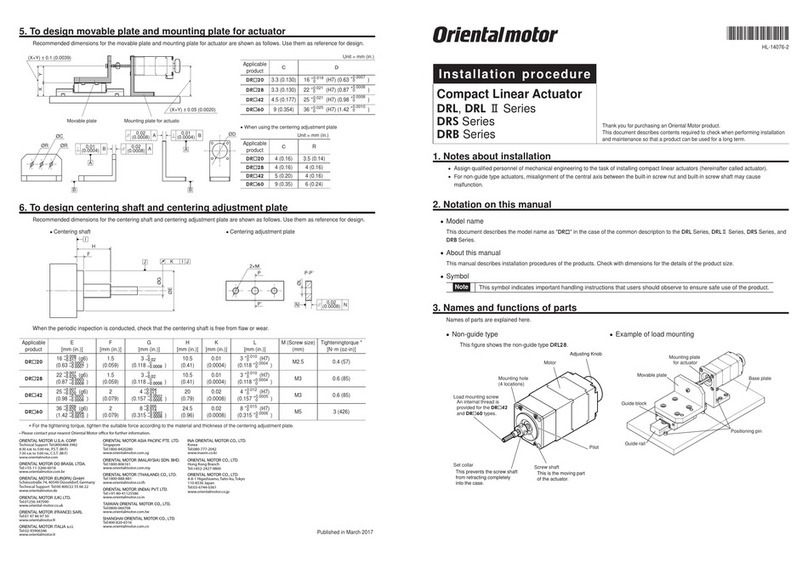

• Please contact your nearest Oriental Motor oce for further information.

4-8-1Higashiueno

,Taito-ku,Tokyo 110-8536

el:03-6744-0361

.orientalmotor.co.jp

Tel:0800-060708

www.orientalmotor.com.tw

Singapore

Tel:1800-8420280

www.orientalmotor.com.sg

Tel:1800-806161

www.orientalmotor.com.my

Korea

Tel:080-777-2042

www.inaom.co.kr

Tel:1800-888-881

www.orientalmotor.co.th

Tel:400-820-6516

www.orientalmotor.com.cn

Tel:+91-80-41125586

www.orientalmotor.co.in

Hong Kong Branch

Safety precautions

The precautions described below are intended to prevent danger or injury to the user

and other personnel through safe, correct use of the product. Use the product only after

carefully reading and fully understanding these instructions.

Handling the product without observing the instructions that accompany a“Warning”

symbol may result in serious injury or death.

General

yDo not use the product in explosive or corrosive environments, in the presence of

ammable gases, locations subjected to splashing water, or near combustibles. Doing

so may result in re or injury.

yAssign qualied personnel the task of installing, wiring, operating/controlling,

inspecting and troubleshooting the product. Failure to do so may result in re, injury

or damage to equipment.

yThe actuator will lose its holding torque when its excitation or the power supply is

turned o. Take measures to keep the moving part in position if the product is used

in vertical operations such as elevator applications. Failure to provide such measures

may cause the moving parts to fall, resulting in injury or damage to equipment.

yDo not use the brake mechanism of the actuator with an electromagnetic brake for

stopping or for safety purposes. The electromagnetic brake is used for the purpose to

hold the moving part and actuator in position. Failure to do so may result in injury or

damage to equipment.

yWith certain types of alarms (protective functions), the actuator may stop when the

alarm generates and the holding torque will be lost as a result. This may result in injury

or damage to equipment.

yWhen the alarm is generated, rst remove the cause and then clear the alarm.

Continuing the operation without removing the cause of the problem may cause

malfunction of the actuator and driver, leading to injury or damage to equipment.

Connection

yKeep the input power voltage of the driver within the specied range. Failure to do so

may result in re.

yFor the driver power supply, use a DC power supply with reinforced insulation on its

primary and secondary sides. Failure to do so may result in electric shock.

yConnect the cables securely according to the wiring diagram. Failure to do so may

result in re.

yDo not forcibly bend, pull or pinch the cable or lead wire. Doing so may cause re.

Repetitive stress or overstress on the connection part may cause damage to the

product.

Operation

yTurn o the driver power in the event of a power failure. Or the actuator may suddenly

start when the power is restored and this may cause injury or damage to equipment.

yDo not turn the excitation to o while the actuator operates. The actuator will stop

and lose its holding power. Doing so may result in injury or damage to equipment.

yCongure an interlock circuit using a sequence program so that when a RS-485

communication error occurs, the entire system including the driver will operate on the

safe side.

Repair, disassembly and modication

yDo not disassemble or modify the actuator and driver. This may cause injury. Refer

all such internal inspections and repairs to the branch or sales oce from which you

purchased the product.

Handling the product without observing the instructions that accompany a“Caution”

symbol may result in injury or property damage.

General

yDo not use the actuator and driver beyond its specications. Doing so may result in

injury or damage to equipment.

yKeep your ngers and objects out of the openings in the actuator and driver. Failure to

do so may result in re or injury.

yDo not touch the actuator and driver while operating or immediately after stopping.

The actuator and driver may be hot and cause skin burn(s).

Transportation

yDo not hold the moving part (screw shaft) of the actuator, cable or lead wire. This may

cause injury.

Installation

yInstall the actuator and driver in the enclosure. Failure to do so may cause injury.

yKeep the area around the actuator and driver free of combustible materials. Failure to

do so may result in re or skin burn(s).

yProvide a cover over the moving part (screw shaft) of the actuator. Failure to do so may

result in injury.

Connection

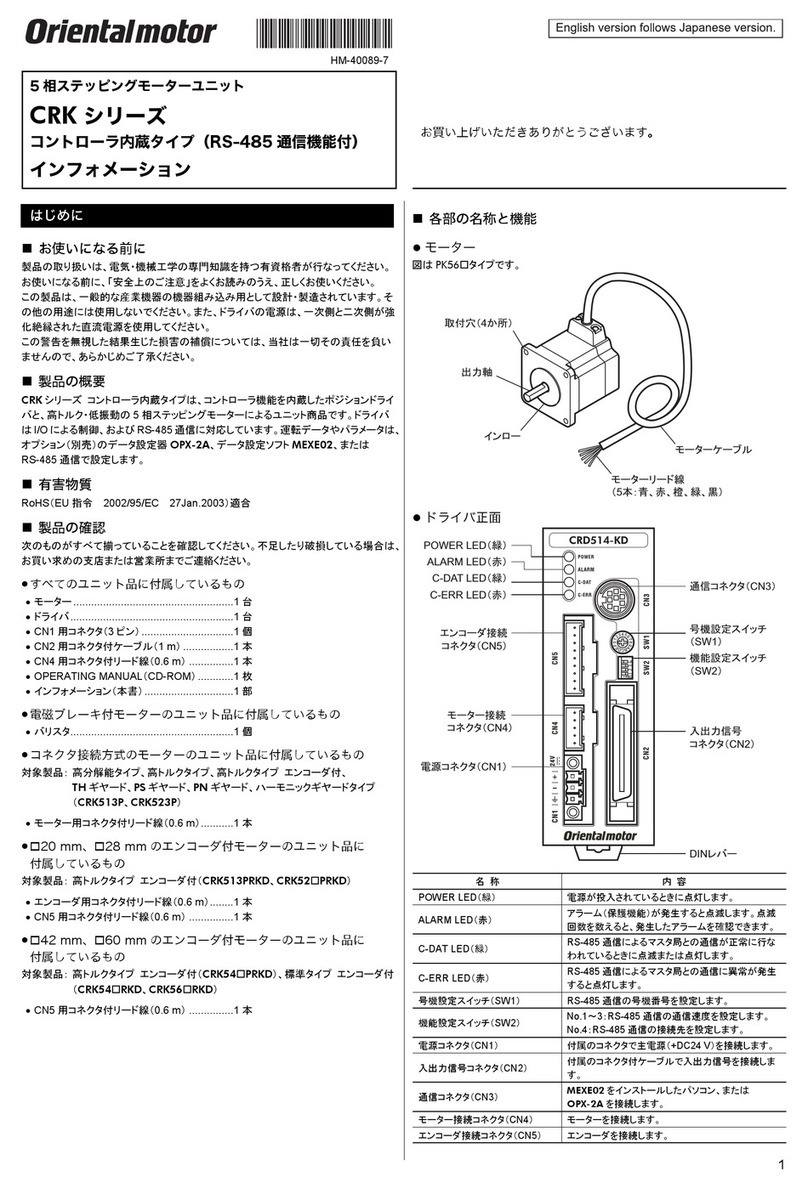

yThe power supply connector (CN1), I/O connector (CN2), data edit connector (CN3)

and RS-485 communication connector (CN6/CN7) of the driver are not electrically

insulated. When grounding the positive terminal of the power supply, do not connect

any equipment (PC, etc.) whose negative terminal is grounded. Doing so may cause

the driver and PC to short, damaging both.

yWhen connecting, check the indication of the driver case and pay attention to the

polarity of the power supply. Reverse-polarity connection may cause damage to

the driver. The power supply circuit and the RS-485 communication circuit are not

insulated. Therefore, when controlling multiple drivers via RS-485 communication,

the reverse polarity of the power supply will cause a short circuit and may result in

damage to the drivers.

Operation

yUse a actuator and driver only in the specied combination. An incorrect combination

may cause a re.

yProvide an emergency stop device or emergency stop circuit external to the

equipment so that the entire equipment will operate safely in the event of a system

failure or malfunction. Failure to do so may result in injury.

yBefore supplying power to the driver, turn all control input to the driver to OFF.

Otherwise, the actuator may suddenly start when the power is turned on and it may

cause injury or damage to equipment.

ySet a suitable speed and acceleration/deceleration rate. Improper setting may cause

loss of the motor synchronism of the actuator and moving the load to an unexpected

direction, which may result in injury or damage to equipment.

yDo not touch the moving part (screw shaft) of the actuator while operating. This may

cause injury.

yBefore moving the moving part (screw shaft) of the actuator directly by the hands,

conrm that the power supply or actuator excitation is turned o and the actuator

current is cut o. Failure to do so may result in injury.

yThe actuator surface temperature may exceed 70 °C (158 °F) even

under normal operating conditions. If the operator is allowed to

approach the running actuator, attach a warning label as shown

below in a conspicuous position. Failure to do so may result in skin

burn(s). Warning label

yImmediately when trouble has occurred, stop running and turn o the driver power.

Failure to do so may result in re or injury.

yStatic electricity may cause the driver to malfunction or suer damage. Do not touch

the driver while the driver power is on. Always use an insulated screwdriver to adjust

the driver switches.

Disposal

yTo dispose of the actuator or driver, disassemble it into parts and components as

much as possible and dispose of individual parts/components as industrial waste. If

you have any question, contact your nearest Oriental Motor branch or sales oce.