2. INSTALLATION

Install the equipment according to the characteristics of humidity and temperature that has been designed to work in. To avoid noise pickup and interference

the relay should be placed away from high current conductors or sources of strong magnetic fields. The device has been designed for the installation on a

panel board with a cutout of 92x92mm using the fixing accessories that come with the relay. Before proceeding with the installation that must be carried

out by a qualified technician, it is recommended to disconnect the power supply on the working area. Orion Italia urges that security procedures be followed

during this installation.

3. WIRING CONNECTION

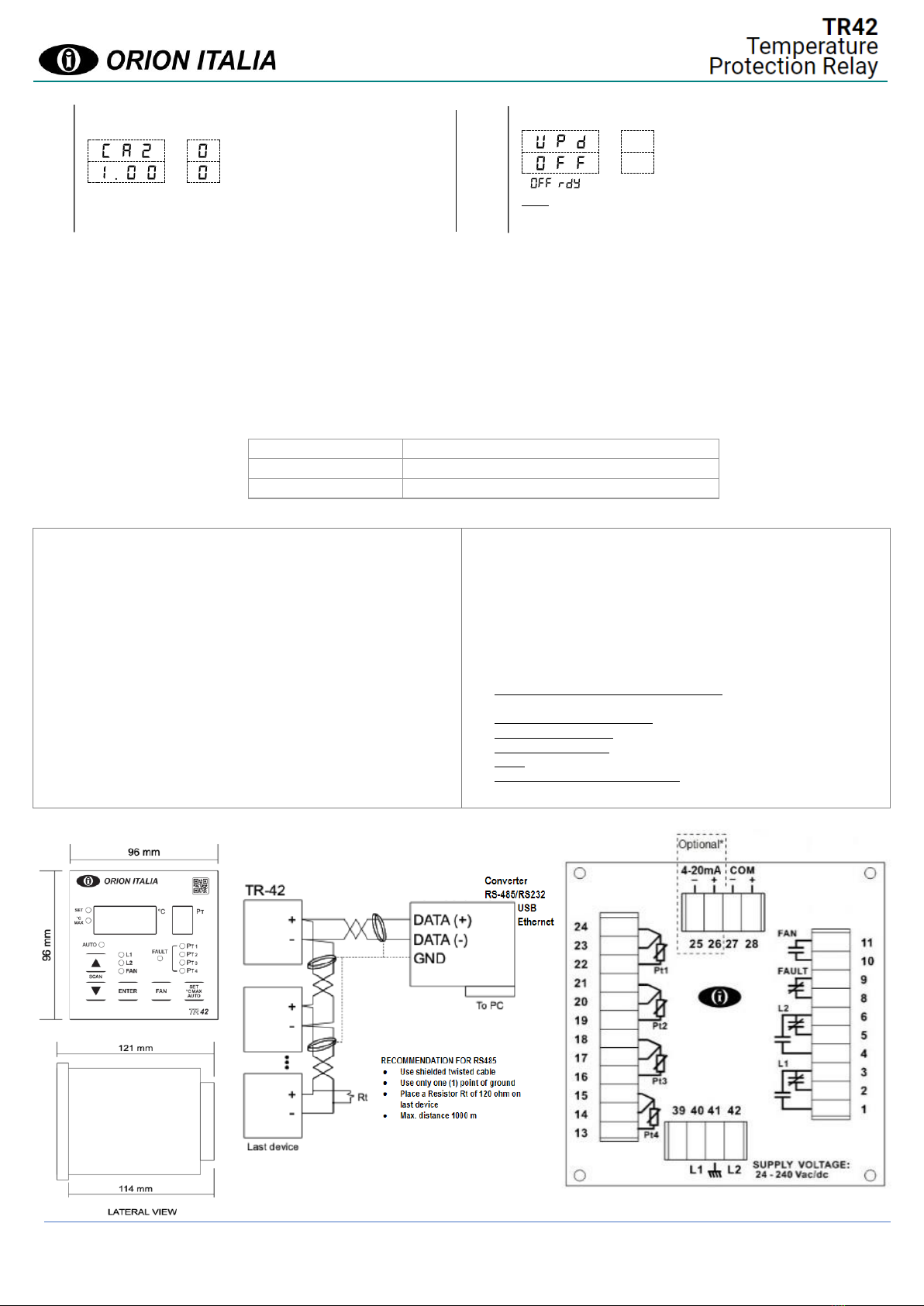

For the connection, follow the diagram on page 4. Herein after the description of the different electric connections:

3.1 POWER SUPPLY

The power supply range is: 24-240 Vcc/Vca (50 –60Hz), -15%, +10% and power must be connected between the terminals 40 and 42. Note: The device does

not have internal fuses. This is to allow the selection of the desired external protection.

IMPORTANT: before doing the dielectric strength test of panel board, where the device is installed, it is necessary to disconnect it from the power line

voltage.

3.2 SENSORS CONNECTION

Each PT sensor has one white wire and two red ones according to the UNI 7937 regulation.

3.3 OUTPUT CONTACTS CONNECTION

In the back side of the device, it is possible to see the output contacts (in absence of power supply). The ALARM relay (L1), TRIP relay (L2) and fan control

(FAN) activate when temperature reaches the setpoint. The FAULT relay (FAULT) opens when power supply is connected and it will be closed when internal

failure occurs, failure of the PT sensors or failure of the power supply. The FAN contact can be used as a control of the cooling system. Note: When using

the contacts for control of inductive loads in Vac (coils of relays, contactors, solenoids), it is essential to limit the overcurrent, or place a R/C group in parallel

to the inductor. If it works in DC, a diode in anti-parallel should be connected.

3.4 SERIAL COMMUNICATION CONNECTION

Communication capabilities are available in the device connecting the RS-485 port in a network (up to 32 devices) controlled by a supervisor device (PC).

The protocol used is Modbus RTU. The connections must be made with shielded twisted wires.

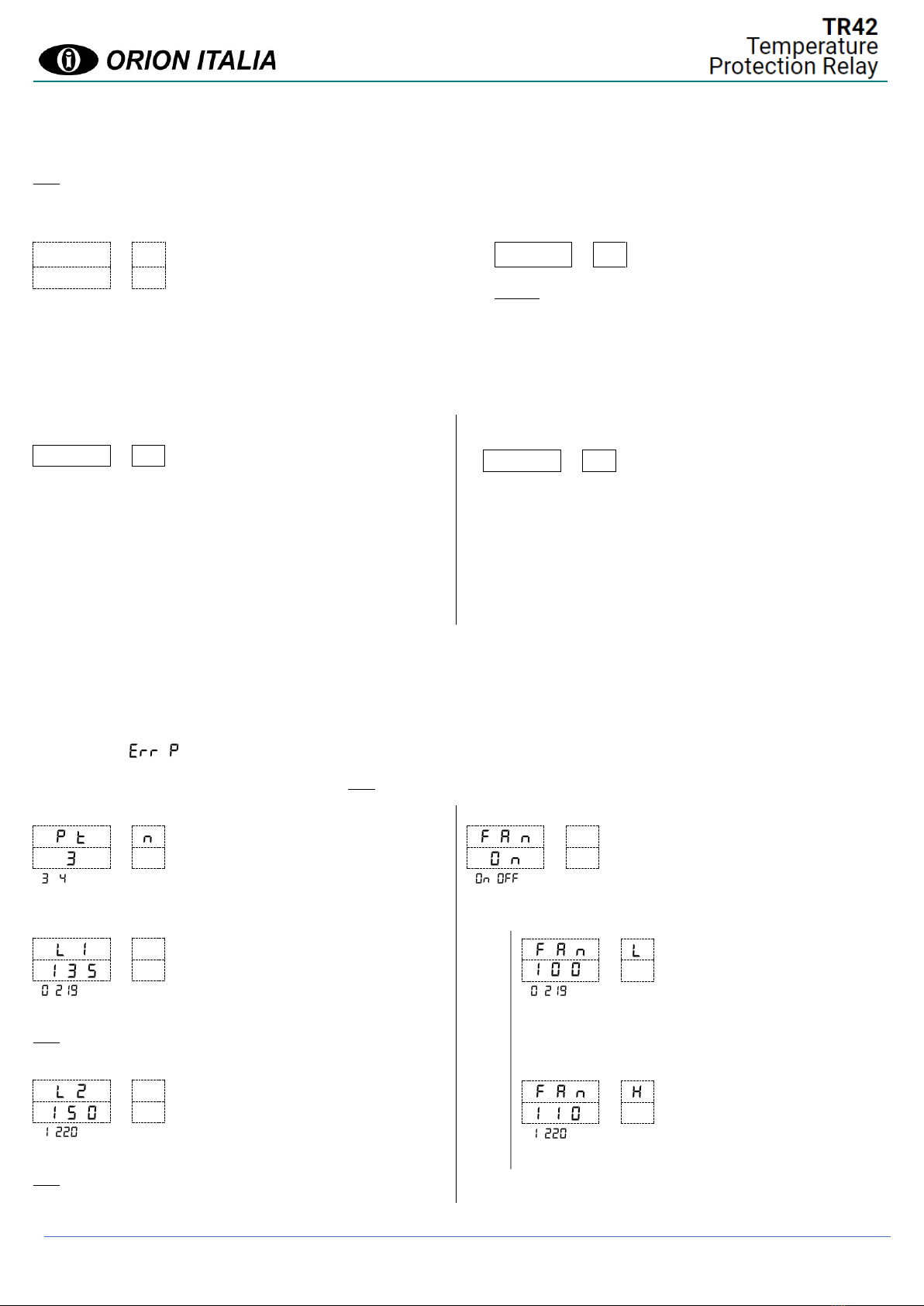

4. FUNCTIONS AND SIGNALS

Display: on the display °C (3 digits) you can observe the value of the temperature and program the settings; through the display PT (1 digit) you can see the

corresponding Pt Channel.

SET LED: if on, it indicates that the user is in the SET mode.

°C MAX LED: if on, it indicates that the user is in the °C MAX mode.

L1, L2 LED: if on, the temperature of one PT sensor reached the corresponding L1 or L2 programmed threshold and the corresponding relay is active.

FAN LED: if on, the “always ON” mode is active and the FAN relay will always be active. If flashing, the temperature of one PT sensor reached the

corresponding FAN programmed threshold or the weekly fan activation function is active and the FAN relay is active.

PT1, PT2, PT3, PT4 LEDs: if on, the temperature of one of the corresponding PT sensors reached the L1 or L2 programmed threshold and the corresponding

relay is active. If flashing, the respective PT sensor is in fault.

FAULT LED: if flashing, it indicates that the flashing PT1, PT2, PT3, PT4, is in fault. The fault cause will be showed through the °C display when positioned

with the arrow buttons on the faulty sensor: Fcc in case of short circuit and Fco for open circuit. Dropout condition for Fcc: T ≥ -7 °C. Dropout condition for

Fco: T ≤ 239 °C.

AUTO LED: if on, it means the user is in the AUTO SCAN mode.

HMI Test: depending on which menu the user is in, by pressing the SET, °C MAX, AUTO button and then keeping the DOWN button pressed, all LEDs and

seven segment LEDs will turn on.

SCAN, AUTO SCAN: in AUTO SCAN mode, the device will automatically scan between each PT sensor temperature showing it on the display every 5sec

allowing the user to see all the temperatures. To exit from the AUTO SCAN function, press any arrow button. The user will still be able to manually scan by

using the UP/DOWN buttons. By pressing the SET, °C MAX, AUTO button until the AUTO LED turns on, the AUTO SCAN function will reactivate. To activate

the AUTO SCAN function in °C MAX, select the °C MAX mode with the same button and keep the UP button pressed for more than 2sec.

FAN: the FAN button allows to switch between “always ON” or Automatic Fan Operation. In “always ON” mode, the fan will always be ON and the FAN LED

will be ON. In automatic mode, the fan will be ON and the FAN LED will blink when one PT sensor reaches the corresponding FAN programmed threshold.

If the setpoint FAN ACTIVATION = OFF, the manual fan will still allow the user to close/open the fan output contact.