READ THIS BEFORE INSTALLATION

Itis very important that the following must becon-

sidered before you install this product.

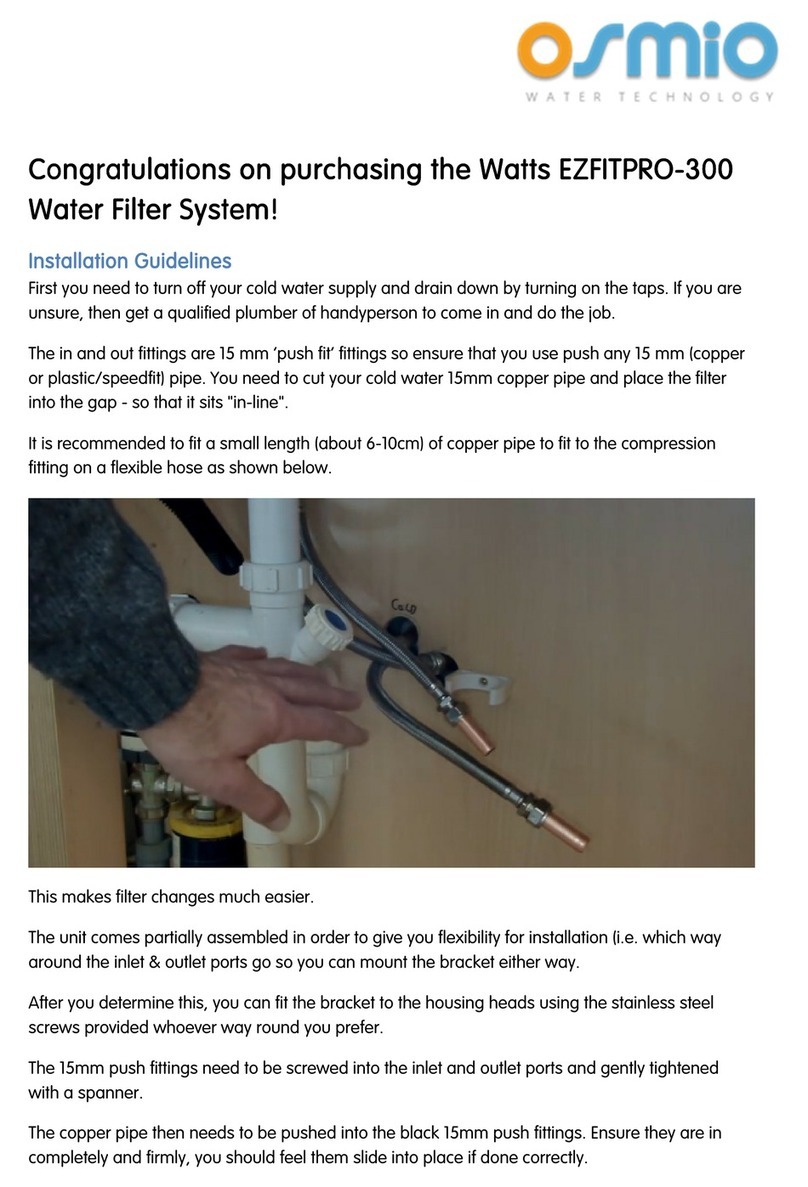

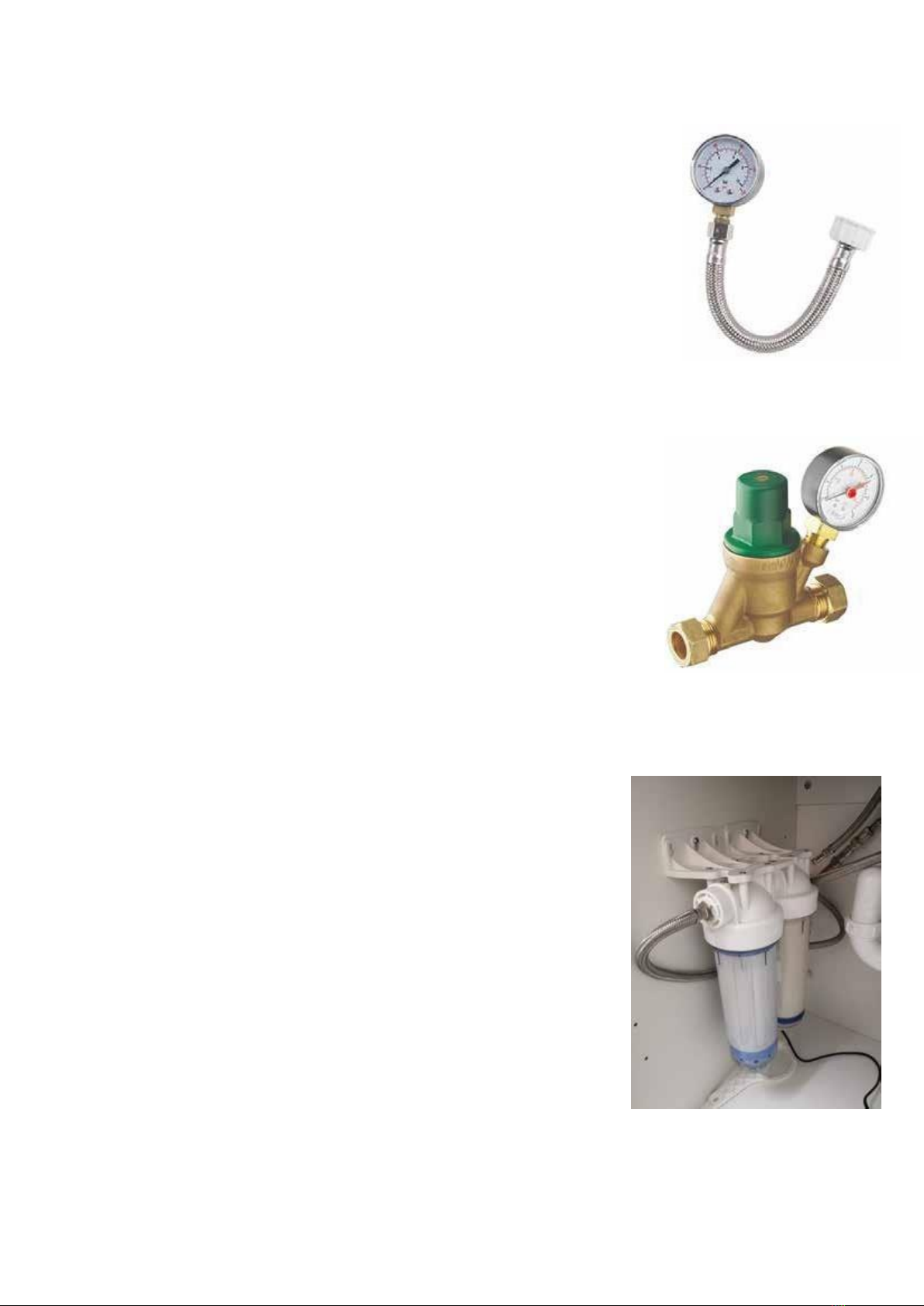

Incomingwaterpressuremustbetestedbeforethe

installation. You can do this by using a pressure

gauge(availableonlineoratplumbersmerchants,

an example shown FIG1). Please note that your

standingwaterpressurecanincreaseupanaddi-

tional 2 bar at night time.

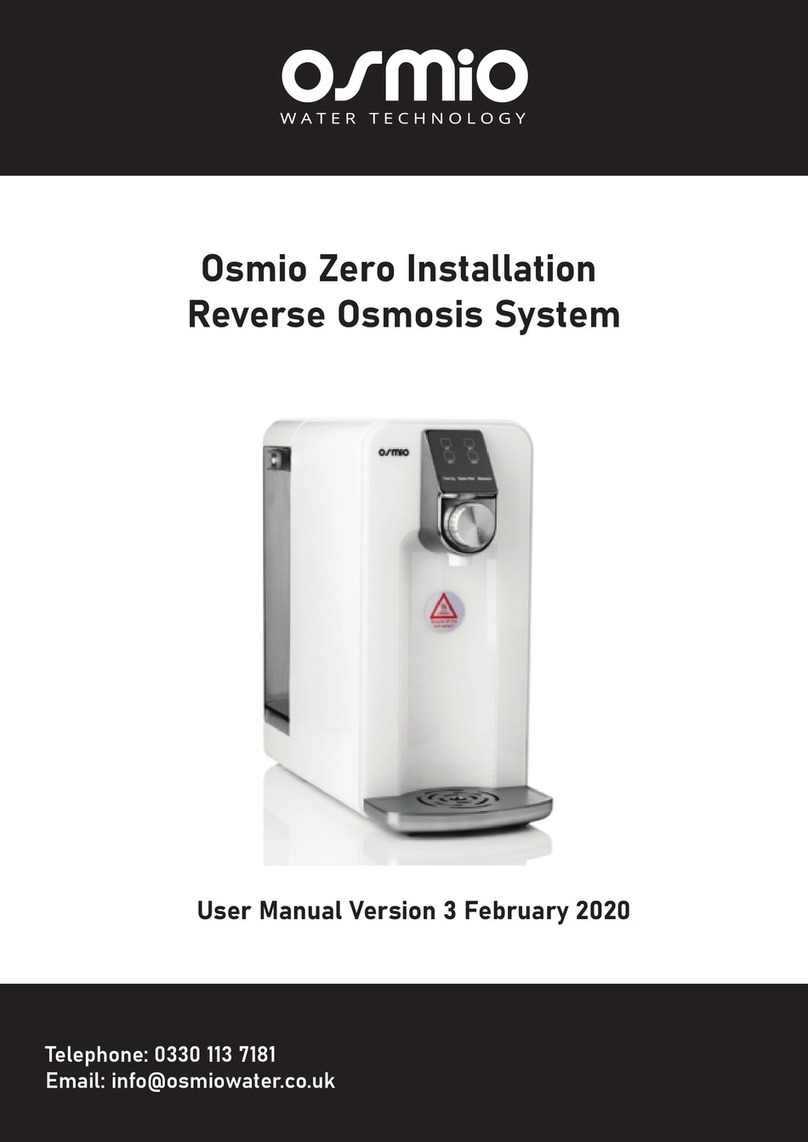

We highly recommending protecting your entire

property with a Pressure Reducing Valve (PRV - see

FIG2) which can protect all appliances and plumbing

from any increases or spikes in water pressure that

canand dohappen, which causes filter systems and

other plumbing to leak.

TOOLS & MATERIALS

The EZFITPRO range can be installed in di"erent

ways using 15mm copper pipe, 15mm speedfit

plastic pipe or using hoses 1/2” male to 15mm

compression fitting (x2).The system comes sup

-

pliedwith15mmpushfittingswhichyou donot

have to use, you can go straight into the 1/2”

female brass. So choice of fitting is up to you and

what is easiest or most appropriate. You will need

the following parts:

Silicone Grease (Plumber’s Grease)

PTFE tape

Spanner & Plumbers Wrench

Philips head screwdriver & Flat edge screwdriver

Pressure gauge

Electric drill

Spirit level

Marker pen

Appropriate screws to mount the filter to the verti

-

cal surface (e.g. wood screws)

Plus any other tools used for the basic plumbing

e.g. pipe cutter, elbows, copper pipe, hoses etc.

FIG1: WATER PRESSURE GUAGE

FIG2: PRESSURE REDUCING VALVE

WITH GUAGE

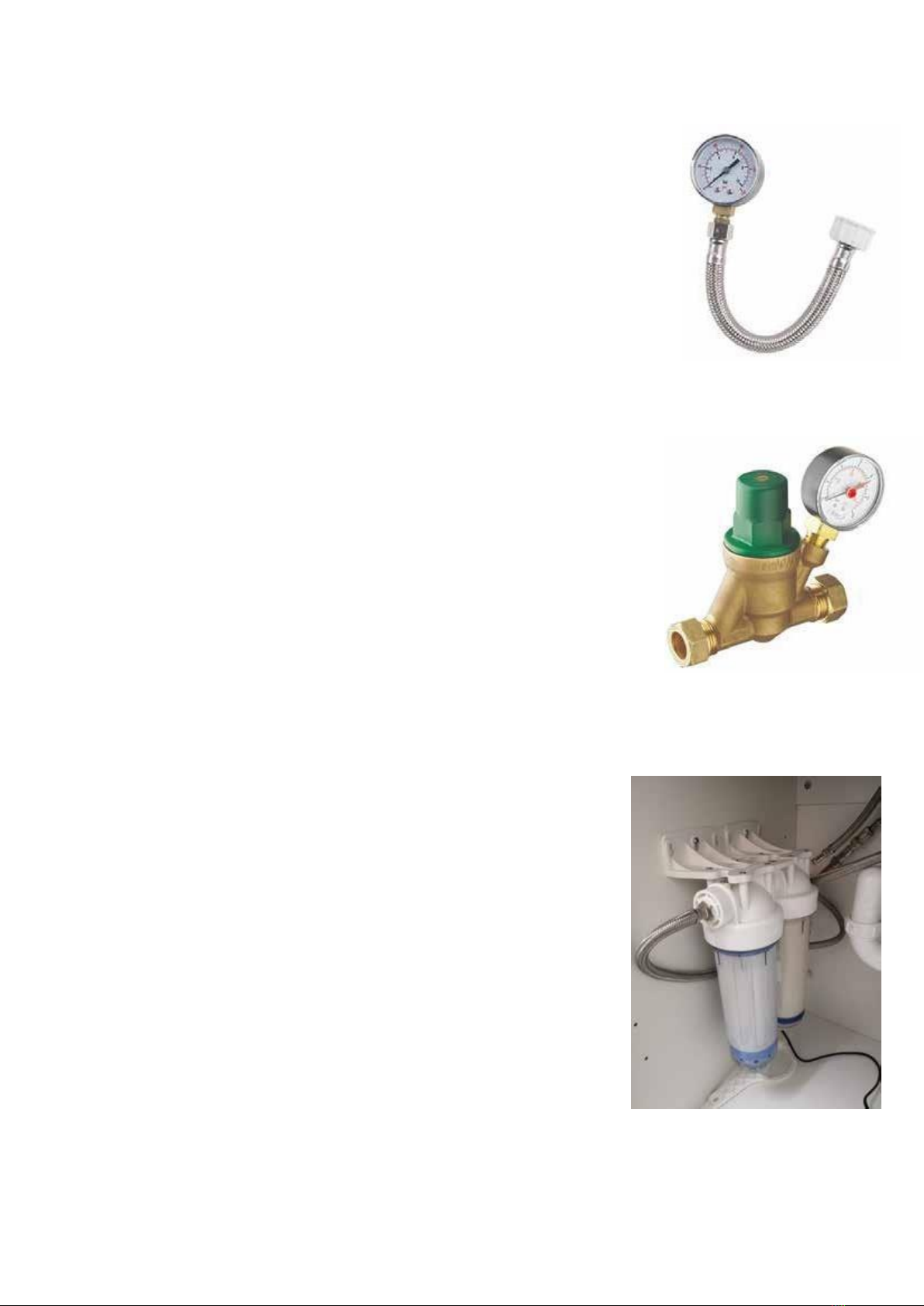

FIG1: OSMIO EZFITPRO-300

INSTALLED WITH HOSES. IT IS AN

EASY WAY TO DO IT IN SOME CASES

AND YOU CAN BUY THE HOSES FROM

ANY PLUMBERS MERCHANT