USER MANUAL FOR THE OSMIO INFINITY HYDROXY GAS/WATER PRODUCTION ELECTROLYSIS SYSTEM

4

Contents

1.0 Introduction ...............................................................................................................6

1.1 Intended Use ...........................................................................................................6

1.2 Principal of Operation ............................................................................................7

2.0 Safety Precautions....................................................................................................7

2.1 Power Safety .........................................................................................................8

2.2 Set Up ....................................................................................................................8

2.3 Operating the System ............................................................................................8

3.0 Installation ................................................................................................................9

3.1 Unpacking...............................................................................................................9

3.2 Check Delivery for Completeness or Damage ....................................................10

3.3 Environmental Conditions ...................................................................................11

3.4 System parts and accessories ............................................................................13

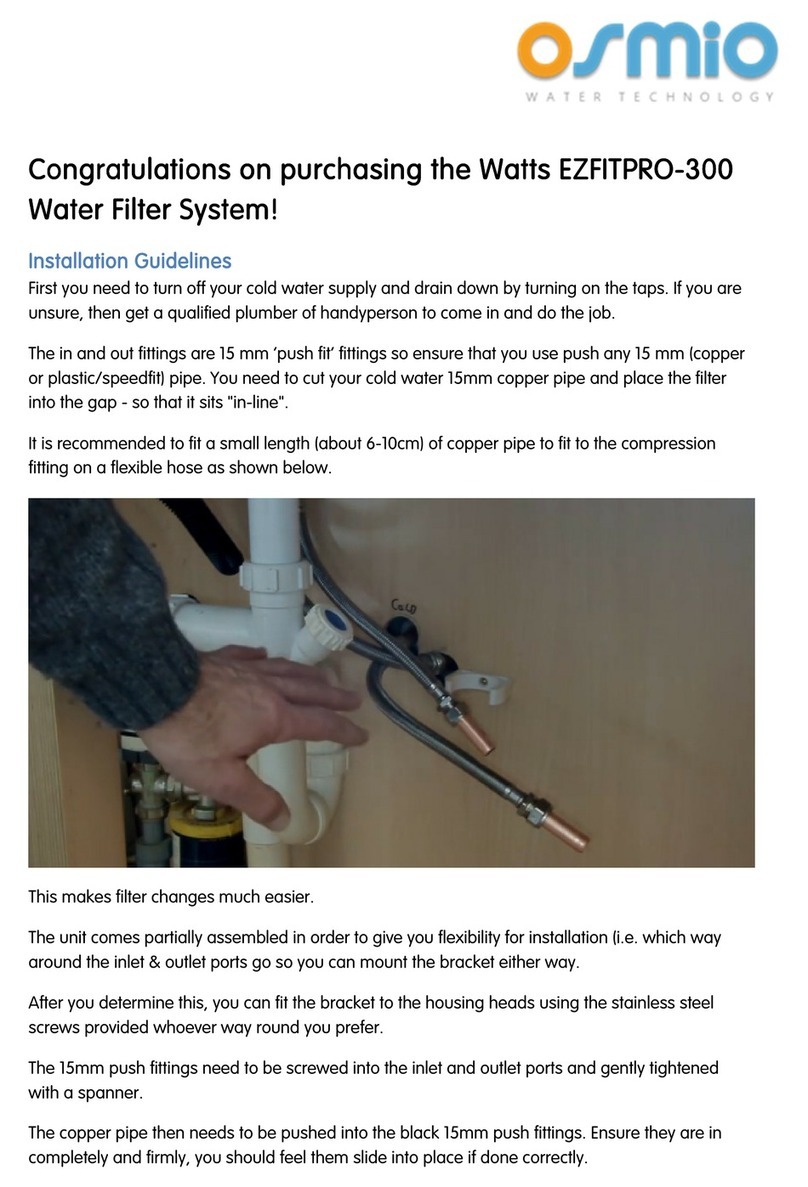

3.5 Assembly Instructions.........................................................................................14

3.6 Performing the Operational Check......................................................................18

3.7 System Settings ..................................................................................................18

3.8 Relative Contraindications ..................................................................................19

3.9 Gas Volume and Calculating the Duty Cycle ........................................................20

4.0 Operating the System .............................................................................................26

4.1 Operating the System - Inhalation .......................................................................26

4.2 Operating the System - Topically ........................................................................27

4.3 Drinking Water ....................................................................................................27

4.4 Shutting the System Off ......................................................................................28

5.0 Emergency Situations .............................................................................................28

6.0 Maintenance............................................................................................................29

6.1 Maintenance in the Home.....................................................................................30

6.2 Cleaning Nasal Cannulas (Home use) .................................................................31

6.3 Maintenance in a Clinical Setting.........................................................................32

6.4 Changing the Humidifier Water ...........................................................................33

6.5 Topping up the Liquid Level.................................................................................33