Carefully slide the module into an open slot in the chassis. Align the module with

the installation guides and ensure that the module is rmly seated against the

backplane. Secure the module by fastening the front panel thumbscrew (push in

and turn clockwise to tighten) to the chassis front.

3) APPLY POWER

AC Power - Standalone Modules

Secure the ground wire to the ground screw located on the back of the module.

Route the power cord through the provided strain relief for additional support and

connect the barrel connector at the end of the wire on the AC/DC adapter to the barrel

connector on the module. Connect the AC/DC adapter to the AC outlet. Conrm

that the module has powered up properly by checking the Power LED located on

the front of the module.

AC Models Rear View: Barrel Connector for AC/DC Power Adapter

NEVER ATTEMPT TO OPEN THE CHASSIS OR

SERVICE THE POWER SUPPLY. OPENING THE

CHASSIS MAY CAUSE SERIOUS INJURYOR DEATH.

THERE ARE NO USER REPLACEABLE OR

SERVICEABLE PARTS IN THIS UNIT.

WARNING!!!

DC Power - Standalone

This module is intended for installation in restricted access areas. (“Les matériels

sont destinés à être installés dans des EMPLACEMENTS À ACCÈS RESTREINT”).

A restricted access area can be accessed only through the use of a special key, or

other means of security.

The over current protection for connection with centralized DC shall be provided in

the building installation, and shall be a UL listed circuit breaker rated 20 Amps, and

installed per the National Electrical Code, ANSI/NFPA-70.

Appropriate overloading protection should be provided on the DC power source

outlets utilized.

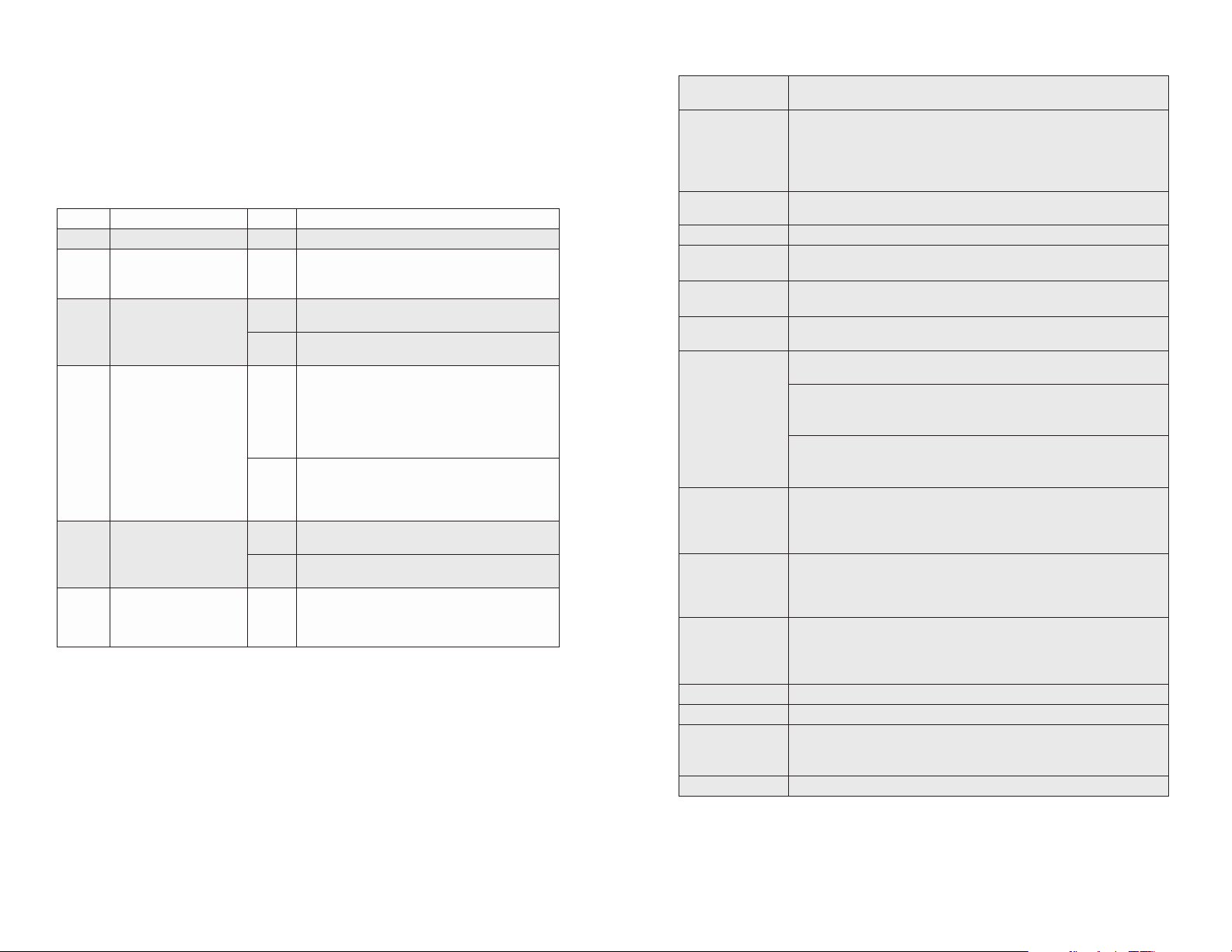

The standalone module requires +7 to +60VDC inclusive of tolerances (1.5A @

9VDC max rated power). See specication table for specic model requirements.

Appropriate overloading protection should be provided on the DC power source

outlets utilized.

DC Models Rear View: 2-Pin Terminal for DC Power

Page 8

Congure the DIP-switches on the remote module for “Self Diagnostic Circuit Test

for Remote Module” (DOWN, DOWN, UP, UP).

Congure the DIP-switches on the local modules for “Self Diagnostic Circuit Test

for Local Module” (UP, UP, UP, UP).

The local XG+ will initiate the circuit test (all DIP-switches to UP) by generating

and sending a test pattern out Port 1 to the remote XG+. Once the remote XG+

detects a good test pattern, the remote XG+ will generate and send a test pattern

back to the local XG+. No data is transmitted on Port 2 of either module when the

self diagnostic circuit test is enabled.

A successful test will produce a green blinking (5Hz) P1 LB LED on the local XG+

and a green blinking (1Hz) P1 LB LED on the remote XG+. If the local XG+ does

not receive a valid response, the P1 LB LED will be blinking amber (5Hz). When

the self diagnostic circuit test is initiated, the trafc received on Port 2 of both XG+

converters will be discarded.

If loopback has been initiated, self diagnostic circuit test DIP-switches will

be ignored. If self diagnostic circuit test has been initiated, loopback DIP-

switches will be ignored.

2) INSTALLING THE MODULE

Wall Mounting - Standalone Module

The wall mounting height of the module should be less than or equal to 2 meters

(6.6 feet) from the oor.

The standalone module is available with or without integrated mounting brackets.

When using the standalone module with integrated mounting brackets, use the four

mounting holes on the module to secure the module to the wall. The module can

accommodate #6 screws (not included).

Standalone modules without mounting brackets can use the optional mounting

bracket kit (2x 4381). Use the four mounting holes on the module to secure the

module to the wall. The module can accommodate #6 screws (not included).

Installation of the module should be such that the air ow in the front, back, side

and top vents of the switch are not compromised or restricted.

The accessory cables should have their own strain relief and do not pull down on

the module.

Rack Mounting - Standalone Module

The standalone modules with integrated mounting brackets or using the optional

mounting bracket kit can be rack mounted using the optional Rack Mount Shelf

(8260-0). Refer to the Rack Mount Shelf user manual (040-08260-001x) for the

proper installation guidelines.

Follow the same guidelines above when rack mounting the module.

Chassis Mounting - Plug-in Modules

Caution: Use proper ESD protection to reduce the risk of damage to your equipment.

Page 7