HIS Business Manufacturing Company

Tel: (619) 447-0009 (800) 292-9831 Fax: (619) 447-4695

General Safety Instrucons

HIS Cable Puller is

designed for producvity

and safety. One person

can easily and eciently

transport, set up and

pull cable. Always

understand the funcon

of the cable puller

before operang. Only

experienced journeymen

should operate cable

pulling equipment.

The cable puller operator should stand o to the side of the puller away

from the line of pull. Always stay clear of the hazard area.

Common Sense, Skill, Safe Working Pracces and Cauon can help avoid most injuries and keep everyone working!

WARNING! Not intended to be used for pulling live electrical cable

Always read instrucons before operang puller

Always inspect puller before operang

1. Inspect cable puller, power lines and surrounding area.

2. Clean up cluered work area before seng up puller.

3. Inspect cable pulling rope. Rope and eyelet must be in

excellent condion. Use high quality, high grade low

stretch cable pulling rope.

4. Never stand on or near the coiled pulling rope as it lays

on the ground.

5. Always pay close aenon to cable pulling. Never let

anyone or anything distract this operaon, unless an

emergency situaon occurs.

6. Never use in water or in dangerous environments.

7. Think SAFETY, SAFETY, SAFETY!

8. Aer pull is completed, dismount puller, clean up and

inspect equipment before storing.

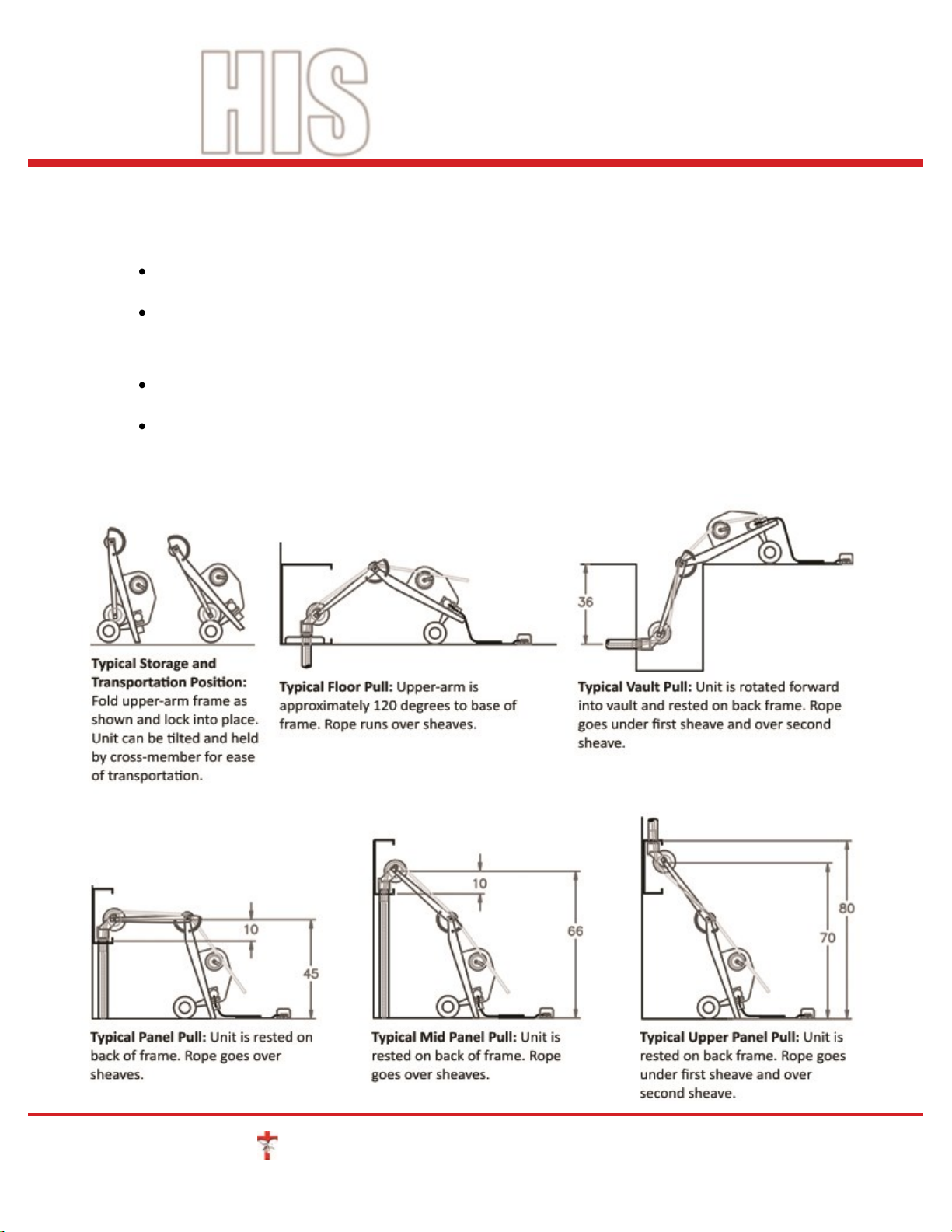

Transporng HIS Cable Puller

Before moving the cable puller, inspect

the equipment to make sure that the

extension arms are secured in the

locking posion using the locking axle

shas provided. Check to be sure power

cord and foot switch is contained with

puller and not loose.

When rolling the cable puller steady the

axle using your foot as you lean the unit

back to nd it’s natural pivot point at

about waist high or 34”. The unit then

becomes easy to transport in either

direcon without exerng undue stress.

When loading and unloading cable

pullers using a hoist, secure one end of

a strap to the handle on the capstan /

motor housing. Loop the other end

through the locking axle sha

NOTE: When seng up cable puller and puller arms BE AWARE OF PINCH POINTS