Beta INSTRUCTIONS

AIR RIVETER

item 1946C 7,8

INSTRUCTION MANUAL FOR AIR RIVETERS

Tool distributed by:

BETA UTENSILI SPA

TO BE ABSOLUTELY DELIVERED TO THE

USER

To reduce the risk of any, damage to people, before using

or repairing the tool, doing any maintenance jobs or

replacing any accessories,

READ ALL THE SECTIONS OF THE INSTRUCTION

MANUAL CAREFULLY.

SAFETY INSTRUCTIONS FOR AIR RIVETERS

It is our aim to supply air tools which allow you to work

efficiently and SAFELY.

It is however understood that YOU are the most important

‘safety device’ for any tool, as taking meticulous care is the

best way of preventing injury.

Although we cannot enumerate all types of risks here, we tried

to lay stress on some of the most significant ones.

Let us remind you that this tool must be used only by skilled

workers and that the machine must never be forced; do not

overload the tool.

RISKS DUE TO CONNECTION TO COMPRESSED AIR

Compressed air may harm people severely.

Do not direct air towards you or any other people.

The air coming out of the hoses may harm people severely;

periodically check whether the hoses and/or fittings are loose

and/or have been damaged.

Whipping hoses may cause severe damage.

Before handling the tool, close the main plant, release residual

pressure and disconnect the tool only when it is not working.

Pressure must not exceed 6.2 bar, as measured at the air inlet

while the tool is working, or the value shown on the tool plate.

RISKS OF VARIOUS KINDS

Stay at a safety distance from the rotating parts of the tool.

Do not wear any accessory round your neck, such as chains or

necklaces. Do not wear any bracelets or loose clothes.

Avoid contact of accessories and tools with your hair.

Avoid contact with any accessories in motion, while the tool is

being used or after it has been used.

Always wear work gloves to reduce the risk of cutting and

burning yourself.

RISKS DUE TO SPLINTERS AND FRAGMENTS

Warning: small splinters and fragments may also harm your

eyes and result in blindness.

Always wear eye protection while using the tool, doing any

maintenance jobs and replacing any accessories or spare

parts. This measure must also be taken by anyone who

works nearby.

RISKS RELATED TO WORKING CONDITIONS

Mind too long hoses left at the work station; stumbling and

falling is likely to result in severe injury.

High noise levels may result in permanent loss of hearing;

wear ear protection, as recommended by the employer

and/or the regulations.

Stay in a safe, well-balanced position.

Repetitive movements and awkward positions combined with

vibrations may cause your hands and arms to be harmed;

special precautions should be taken.

Do not breathe dust and waste; partially protect yourself

with a filtering mask.

Both the workers and the maintainers must be physically fit for

the size, weight and power of this tool.

This tool was not designed to be used in areas exposed to the

risk of explosion and is not so insulated as to come into contact

with power sources.

OTHER SAFETY REQUIREMENTS

This tool and its parts and accessories must not be modified

and/or tampered with.

The building material of this tool may be subject to wear.

Working with compressed air tools may result in high

vibrations; therefore, take any precautions needed.

Prevent your hands from being trapped between the tool and

any object.

FOR FURTHER INFORMATION ABOUT SAFETY REFER TO

THE FOLLOWING:

The documents, information and instructions supplied with this

tool;

The employer, trade associations and/or trade unions;

The EEC Council and/or local authorities

“Safety Requirements for Hand Held Non-Electric Tools”,

available at: European Committee for Standardization, Rue de

Stassart 36, 1050 Brussels, Belgium.

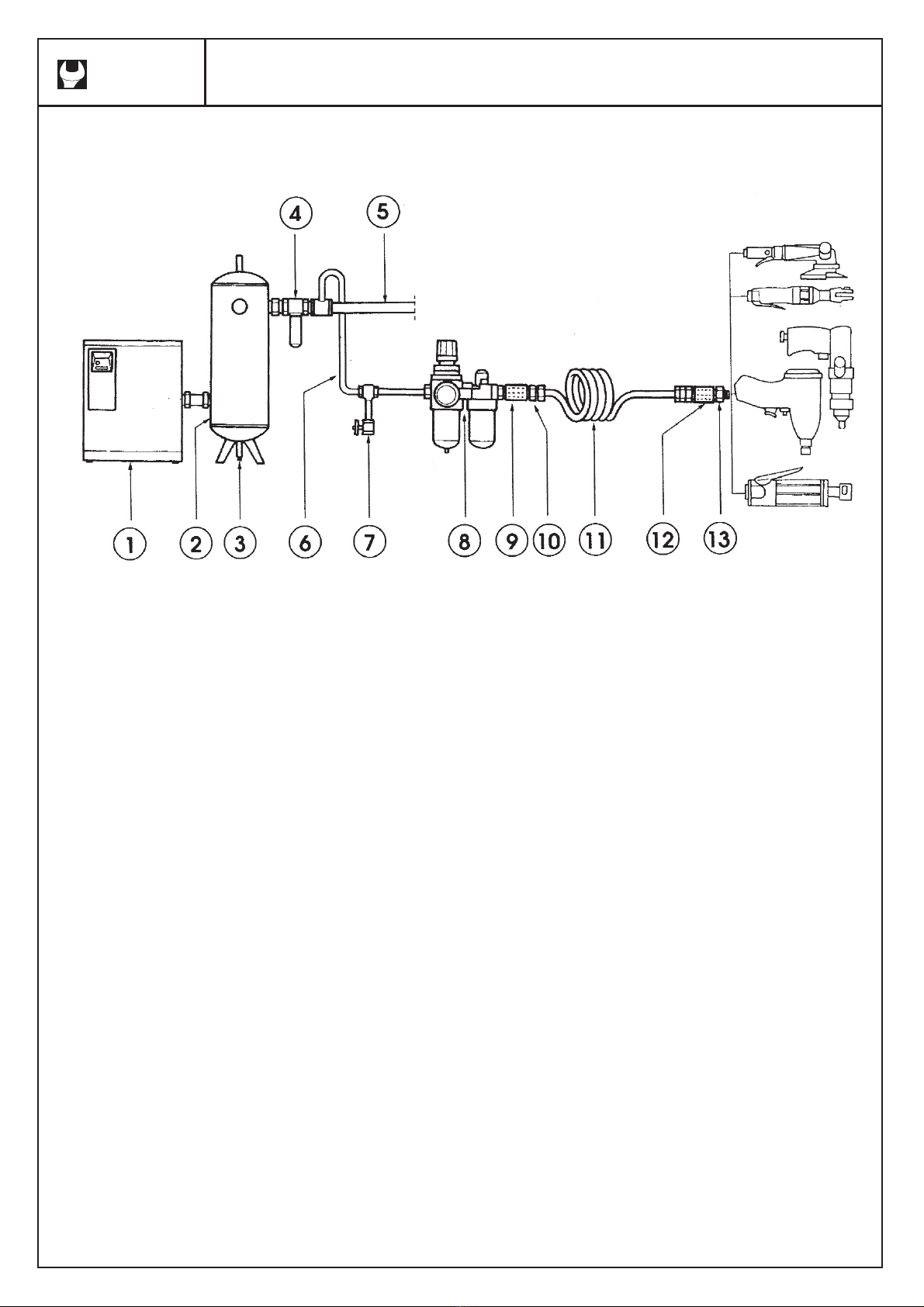

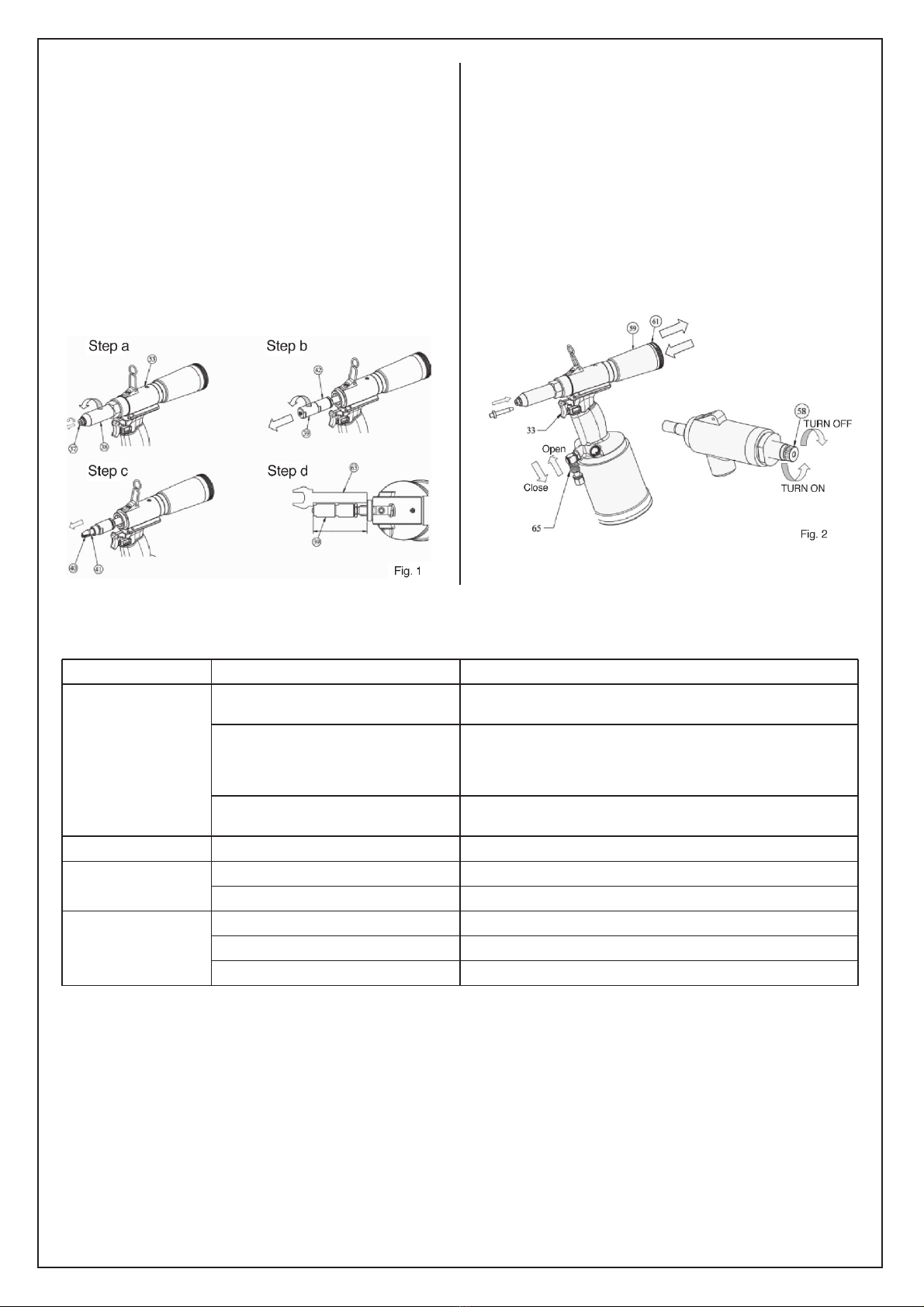

REQUIREMENTS FOR PROPER AIR CONNECTION

Feed the tool with clean air, free from water or condensate, at

a pressure of 6.0 bar, as measured at the air inlet, while the

tool is working.

An excessively high pressure results in a shorter life for the

mechanical parts and may cause people to be severely

harmed.

Connect the tool to the feeding plant, using accessories of the

same size as that shown in the enclosed drawing.

Do not fix any quick couplers directly into the air inlet.

Consult the instructions to connect the accessories properly.

Consult the specifications in this manual.