RUN LINK WIZARD

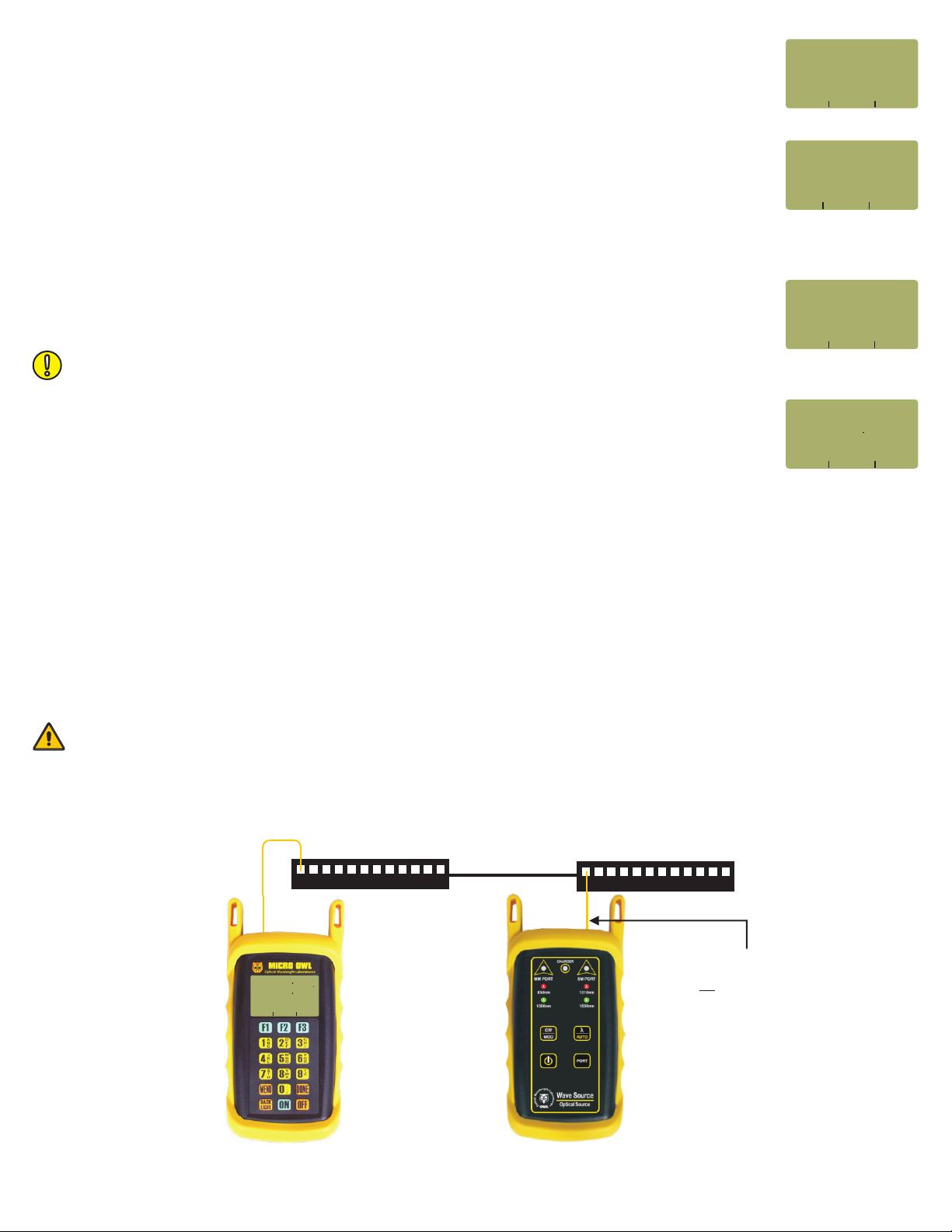

STEP 12 From the OPERATING MODE menu, select CERTIFY LINK.

STEP 13 From the START MENU, press <1>LINK WIZARD.

STEP 14 From the STORED LINKS menu, highlight the stored link name you wish to use and

press <F2> to select.

STEP 15 OPTIONAL: you may change the link name to something that better describes the

group of fibers you are testing.

Press <DONE> to continue.

STEP 16 Change the LINK DATE to the date the fiber will be tested using the format MM-DD-

YY.

Press <DONE> when you are finished entering the current date.

STEP 17 Highlight the cabling standard to use for the set of fibers you are testing.

Press <F2> to select the chosen standard.

STEP 18 Highlight the fiber type of the network under test.

Press <F2> to select the fiber type.

STEP 19 Enter the end-to-end length of the fiber link under test in meters.

Press <DONE> to continue.

STEP 20 Enter the number of connections (i.e. patch panels) in the link under test. Typical fiber

networks will have 2 connections – one for a patch panel located at each end of the link.

Press <DONE> to continue.

STEP 21 Enter the number of splices in the link under test. Splices can be either fusion or

mechanical. Typical singlemode networks will have zero splices.

NOTE: some connectors use mechanical splice technology for termination. If the link under

test is terminated with these “no-polish, no-epoxy” type connectors, they should be considered

as mechanical splices.

Press <DONE> to continue.

STEP 22 Review your Link Wizard setup.

If correct, press <F1> and continue on to the next step.

If changes need to be made, press <F3> and go back to STEP 15.

It is important to set the current date in order to ensure that the correct date appears on the certification reports.

XXXXXXXXXXXXXXXXXXXXX

X X XXXXXX<1>LINK WIZARD

XX XXXXXXXX<2>MAIN MENU

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXX X XXXXXXSTART MENU

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XX x x xXxxxxxFiber Link 2

x XX XXXXXXXXNEXT SELECT

XX x x xXxxxxxFiber Link 3

XX x x xxXxxxxFiber Link 4

XXXX X XXXXXSTORED LINKS

_____________________

XX x x XxxxxxxFiber Link 1

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

x XXX XXX X<--- SHIFT --->

XXXXXXXXXXXXXXXXXXXXX

[Fiber Link 1 ]x x xXxxx

LINK NAME:X XXXXXXXXXXX

_____________________

XXXXXXXXXXXXXXXXXXXXX

X X X XXXXXUSER DEFINED #1

X X X XXXXXUSER DEFINED #2

x XX XXXXXXXXNEXT SELECT

X X XXXXXXXISO/IEC 11801

xx X XXXXFIBER STANDARDS

_____________________

X X XXXXXTIA-568B 3

XXXXXXXXXXXXXXXXXXXXX

XX X X xx50 0um MM

x XX XXXXXXXXNEXT SELECT

xx X xOUTDOOR SM

XXXXX X XXXXXFIBER TYPES

_____________________

XX X xxINDOOR SM

XX X X xxx62 5um MM

(A CONNECTION IS WHENX X X

TWO FIBER CONNECTORSX X X

MATE USUALLY A PATCHXX X X

x XXX XXX X<--- --->SHIFT

PANEL)XXXXXXXXXXXXXXX

[2 ]X XXXXXXXXXXXXXXXXX

INLINE CONNECTIONS?X XX

_____________________

SPLICES IN THE FIBERX X X X

BEING TESTED:X XXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

x XXX XXX X<--- --->SHIFT

XXXXXXXXXXXXXXXXXXXXX

[0 ]X XXXXXXXXXXXXXXXXX

ENTER THE NUMBER OFX X X XX

_____________________

[1 TO 65535]X X X

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

x XXX XXX X<--- --->UNITS

XXXXXXXXXXXXXXXXXXXXX

[01000]X XXMETERS

ENTER FIBER LENGTH:X X XX

_____________________

01000 Metersx xxxxxxxxx

02 Connectionsx xxxxxxx

00 Splicesx xxxxxxxxxxx

X XXXXXXXXXXXXX XXYES NO

62 5um MMx x

IS THIS CORRECT?X X XXXXX

TIA-568-B 3X XX

_____________________

Standard »

Length »

Connections »

Splices »

Fiber Type »

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

X XXX XXX X<--- SHIFT --->

XXXXXXXXXXXXXXXXXXXXX

[03-20-08]

DATE:X[MM/DD/YY]

_____________________