STEP 17 Change the LINK DATE to the date the fiber will be tested using the format MM-DD-

YY.

Press <DONE> when you are finished entering the current date.

STEP 18 Highlight the cabling standard to use for the set of fibers you are testing.

Press <F2> to select the chosen standard.

STEP 19 Highlight the fiber type of the network under test.

Press <F2> to select the fiber type.

STEP 20 Enter the end-to-end length of the fiber link under test in meters.

Press <DONE> to continue.

STEP 21 Enter the number of connections (i.e. patch panels) in the link under test. Typical fiber

networks will have 2 connections – one for a patch panel located at each end of the link.

Press <DONE> to continue.

STEP 22 Enter the number of splices in the link under test. Splices can be either fusion or

mechanical. Typical multimode networks will have zero splices.

NOTE: some connectors use mechanical splice technology for termination. If the link under

test is terminated with these “no-polish, no-epoxy” type connectors, they should be considered

as mechanical splices.

Press <DONE> to continue.

STEP 23 Review your Link Wizard setup.

If correct, press <F1> and continue on to the next step.

If changes need to be made, press <F3> and go back to STEP 16.

STEP 24 Press <F1> until the asterisk (*) is in front of 850nm (as shown at right).

Press <F2> to begin the SET REFERENCE procedure for 850nm.

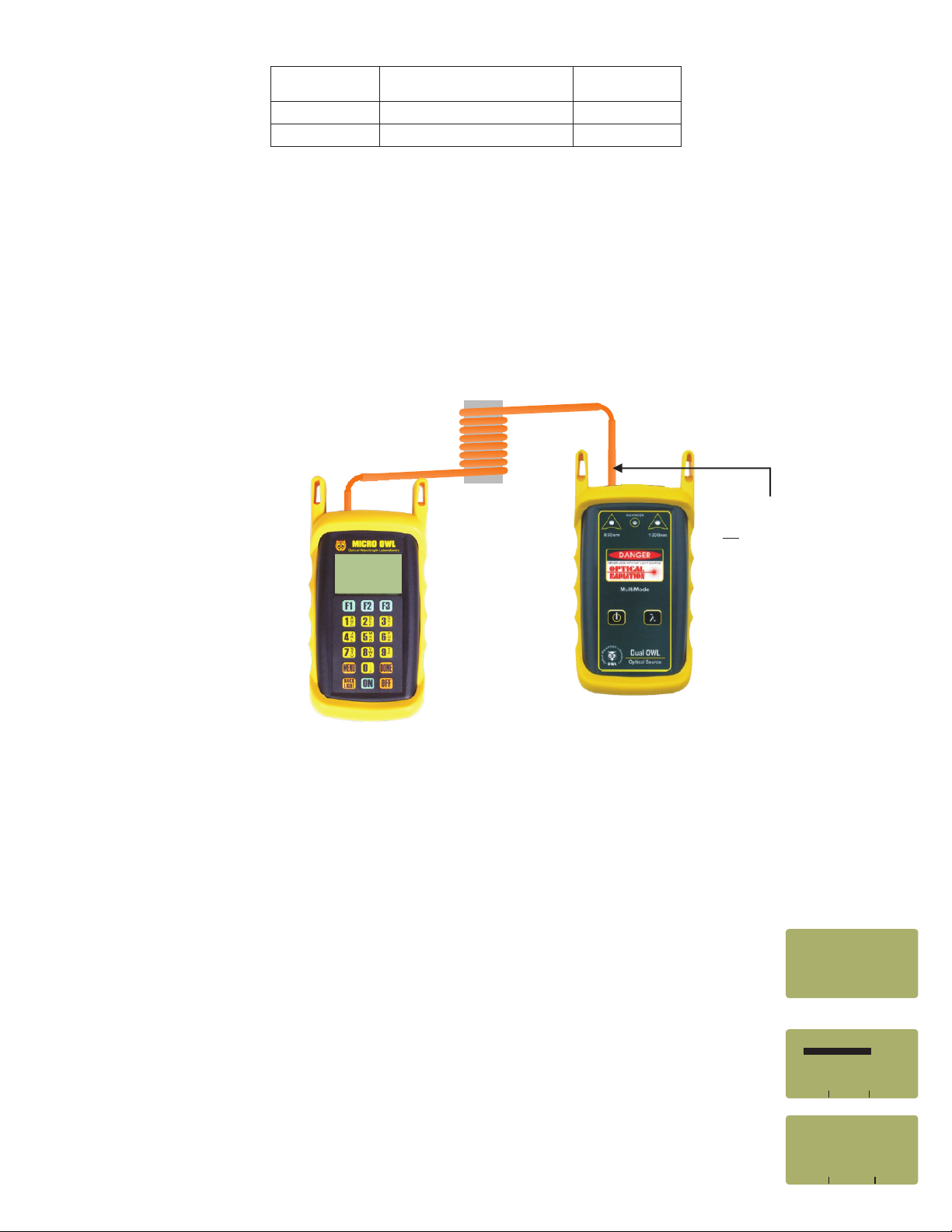

STEP 25 Connect the detector meter and 850nm light source (left-hand port) together with the

mandrel-wrapped cable as shown in Figure 4.

Press <F1> to continue.

STEP 26 Make sure that the 850nm light source port is powered ON and selected (the indicator LED on the left-

hand side will be lit).

STEP 27 Confirm setting the 850nm reference.

Pressing <F1> to continue. You will be returned to the SET SOURCE REFERENCES screen.

NOTE: if you are also testing at 1300nm, you will need to connect a separate mandrel-

wrapped patch cable to the 1300nm port.

It is important to set the current date in order to ensure that the correct date appears on the certification reports.

WAVELEN REF dBmX X

---------------------

* 850nm NOT SETX X X

X XXXX XXXX XWAVE SET DONE

X X X1300nm NOT SET

XXXXXXXXXXXXXXXXXXXXX

SET REFERENCESX

_____________________

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

X XXX XXX X<--- SHIFT --->

XXXXXXXXXXXXXXXXXXXXX

[03-20-08]

DATE:X[MM/DD/YY]

_____________________

XXXXXXXXXXXXXXXXXXXXX

X X X XXXXXUSER DEFINED #1

X X X XXXXXUSER DEFINED #2

x XX XXXXXXXXNEXT SELECT

X X XXXXXXXISO/IEC 11801

xx X XXXXFIBER STANDARDS

_____________________

X X XXXXXTIA-568B 3

XXXXXXXXXXXXXXXXXXXXX

XX X X xx50 0um MM

x XX XXXXXXXXNEXT SELECT

xx X xOUTDOOR SM

XXXXX X XXXXXFIBER TYPES

_____________________

XX X xxINDOOR SM

XX X X xxx62 5um MM

[1 TO 65535]X X

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

x XXX XXX X<--- --->UNITS

XXXXXXXXXXXXXXXXXXXXX

[01000]X XXMETERS

ENTER FIBER LENGTH:X X XX

_____________________

(A CONNECTION IS WHENX X X

TWO FIBER CONNECTORSX X X

MATE USUALLY A PATCHXX X X

x XXX XXX X<--- --->SHIFT

PANEL)XXXXXXXXXXXXXXX

[2 ]X XXXXXXXXXXXXXXXXX

INLINE CONNECTIONS?X XX

_____________________

SPLICES IN THE FIBERX X X X

BEING TESTED:X XXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

x XXX XXX X<--- --->SHIFT

XXXXXXXXXXXXXXXXXXXXX

[0 ]X XXXXXXXXXXXXXXXXX

ENTER THE NUMBER OFX X X XX

_____________________

01000 Metersx xxxxxxxxx

02 Connectionsx xxxxxxx

00 Splicesx xxxxxxxxxxx

X XXXXXXXXXXXXX XXYES NO

62 5um MMx x

IS THIS CORRECT?X X XXXXX

TIA-568-B 3X XX

_____________________

Standard »

Length »

Connections »

Splices »

Fiber Type »

850nm

DONE

SOURCE

CONNECT

_____________________

XX850nm

X XXXXXXXXXXXXX XXYES NO

xxREF?

_____________________

xxxSET