3

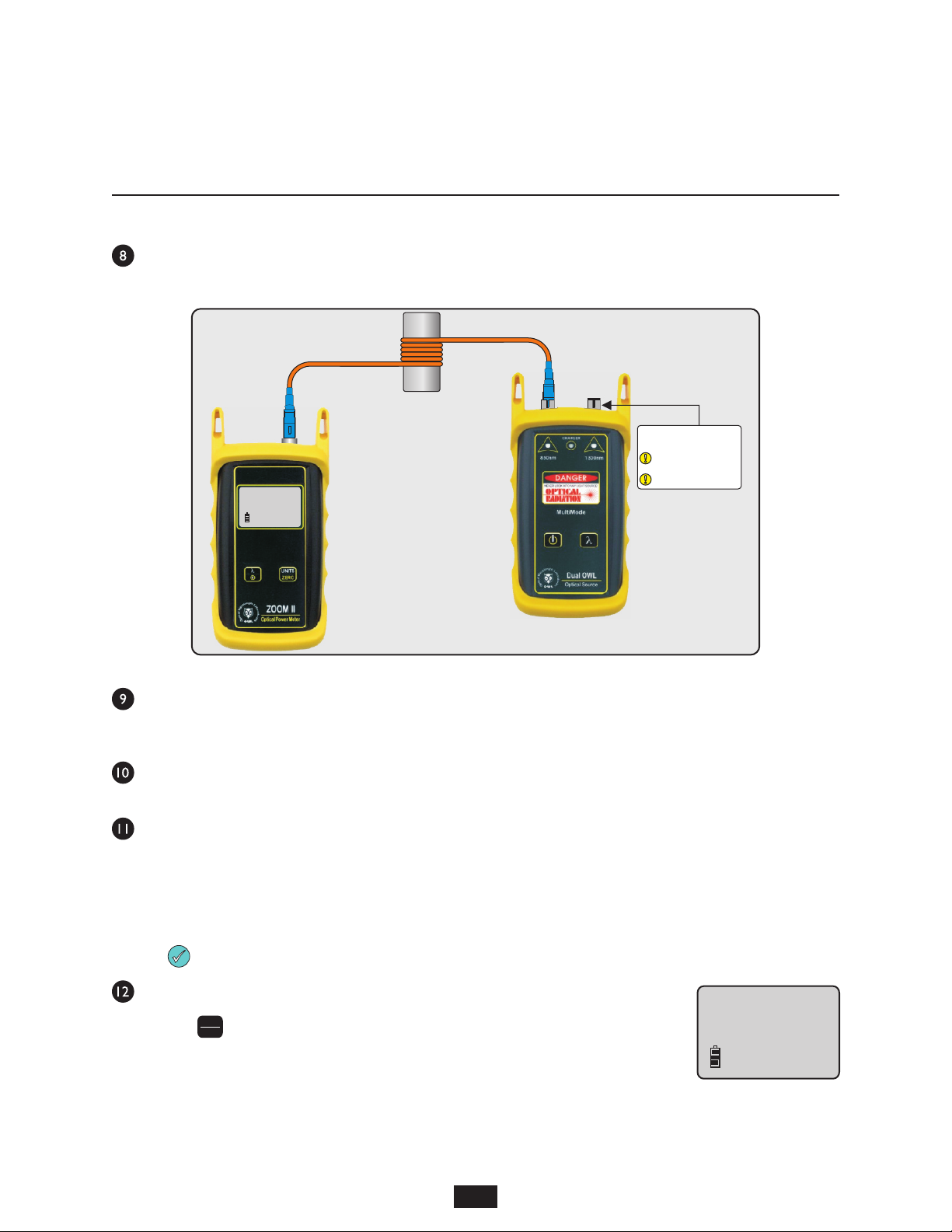

PART 1 – VERIFY EQUIPMENT OPERATION; cont.

Connect a mandrel-wrapped patch cable between the detector port on the ZOOM 2 and the left-hand port (850nm) on the

Dual OWL(Figure 4).

Compare the reading on the ZOOM 2 to Table 1 for acceptable power levels. The mandrel-wrapped patch cable should be

replaced if it is below the acceptable power level. Once proper operation has been verified, remove the mandrel-wrapped

cable from the power meter and light source, then continue to the next step.

Connect a second mandrel-wrapped patch cable between the detector port on the ZOOM 2 and the left-hand port (850nm)

on the Dual OWL(Figure 4).

Compare the reading on the ZOOM 2 to Table 2 for acceptable power levels. The patch cable should be replaced if it is

below the acceptable power level. Once proper operation has been verified, leave the mandrel-wrapped patch cable

connected to the power meter and light source, then continue on to the next step.

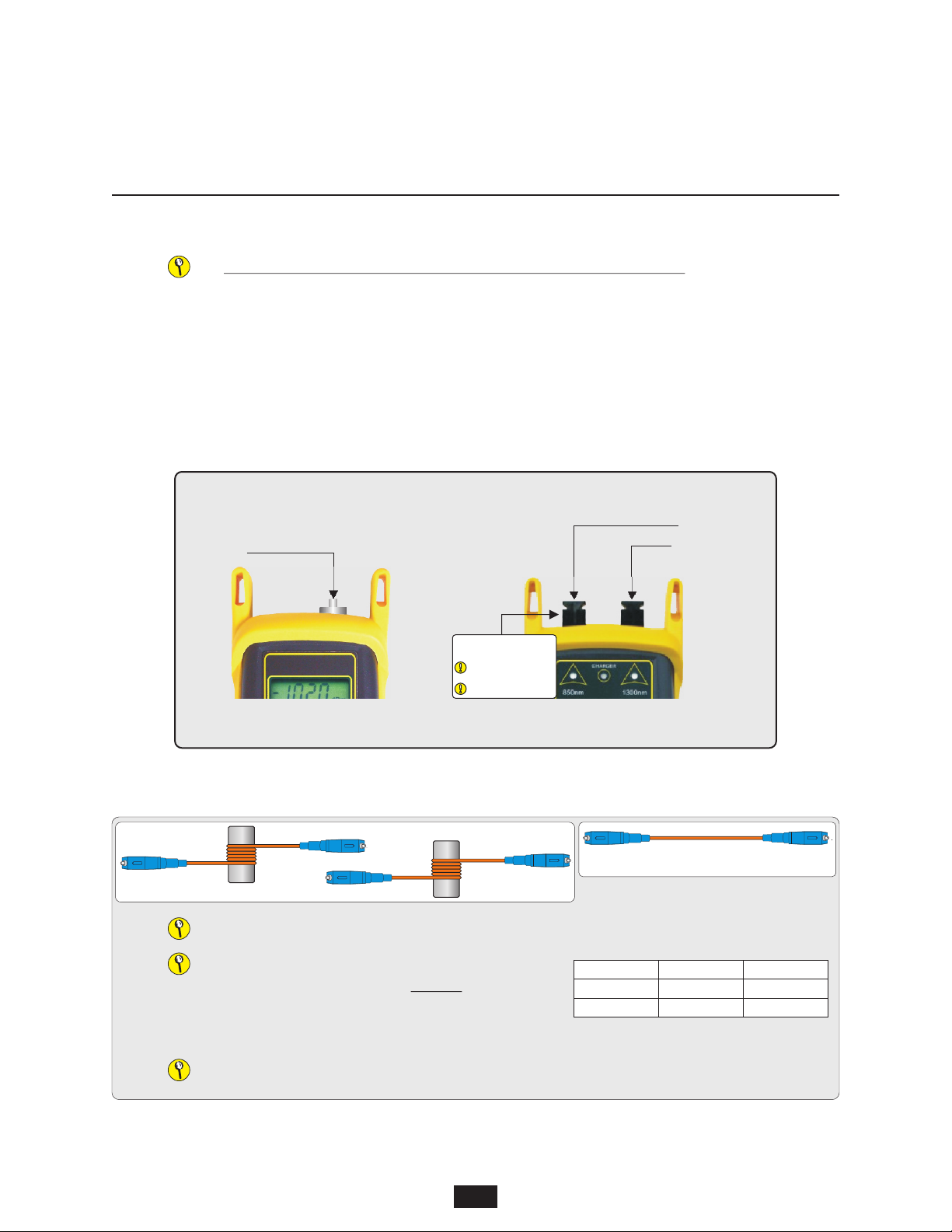

PART 2 – SET REFERENCE

Setting a reference is commonly referred to as “zeroing”.

Ensure the power meter and light source are still connected together (Figure 4), then press and

hold on the ZOOM 2 to set the reference for 850nm.

The ZOOM 2 display should change to show readings in ‘dB’, and the power reading should be

approximately 0.00 dB. This means that the meter and light source have been successfully

“zeroed” at 850nm.

UNITS

ZERO

QUICK REFERENCE GUIDES

Optical Power Meter: ZOOM 2

Fiber Optic Light Source: DUAL OWL Series PAGE 3 OF 5

FIGURE 4

Mandrel-wrapped

cable connection

dBm

. . .20.00

-

850

nm

SC connectors shown here;

connector style may vary

LIGHT SOURCE

CONNECTOR PORTS

Do NOT insert APC connector

into either light source port

dBm

.2. .0.00

-

850

nm