Belt Sander Safety Warnings

6

Hold power tool by insulated gripping surfaces, because the belt may contact its

own cord. Cutting a "live" wire may make exposed metal parts of the power tool

"live" and could give the operator an electric shock.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

Recommendations for the use of a residual current device with a rated residual

current of 30mA or less.

It is recommended that the extension lead is a maximum of 25m in length. Do Not

use multiple extension leads.

Unplug the sander before changing accessories. Accidental start-ups may occur if

the sander is plugged in while changing an accessory.

Disposing of dust. Be extremely careful of dust disposal, materials in fine particle form

may be explosive. Do not throw sanding dust on an open fire. Spontaneous

combustion, may in time, result from a mixture of oil or water with dust particles.

Always wear eye protection and a dust mask for dusty applications and when

sanding overhead. Sanding particles can be absorbed by your eyes and inhaled easily

and may cause health complications.

Use special precautions when sanding chemically pressure treated timber, paint

that may be lead based, or any other materials that may contain carcinogens. A

suitable breathing respirator and protective clothing must be worn by all persons

entering the work area. Work area should be sealed with plastic sheeting and persons

not protected should be kept out until work area is thoroughly cleaned.

Do not ‘wet sand’ with this sander.Liquids entering the motor housing are an

electrical shock hazard.

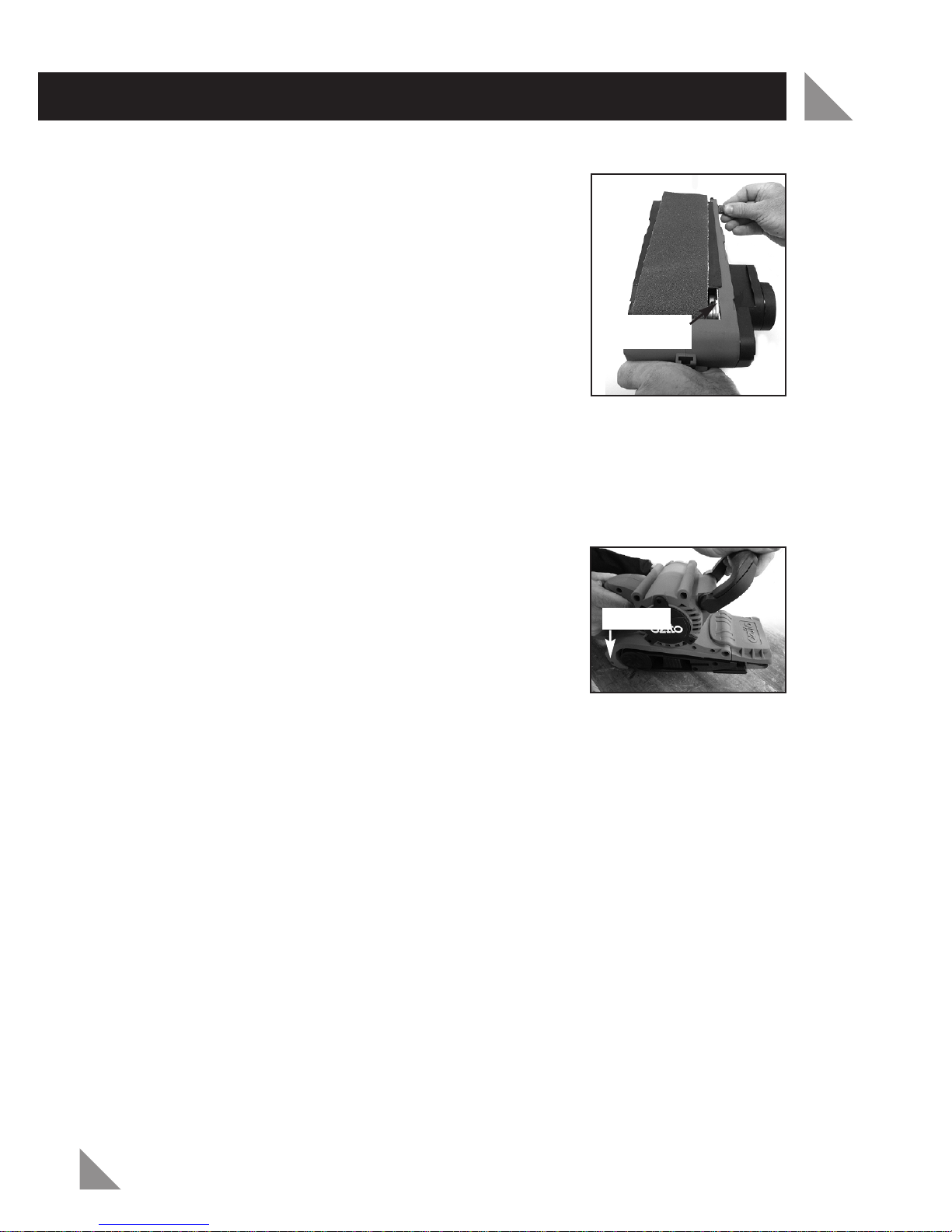

Keep fingers and clothing away from the belt. They could get cut or wedged

between the pulley, belt and motor housing.

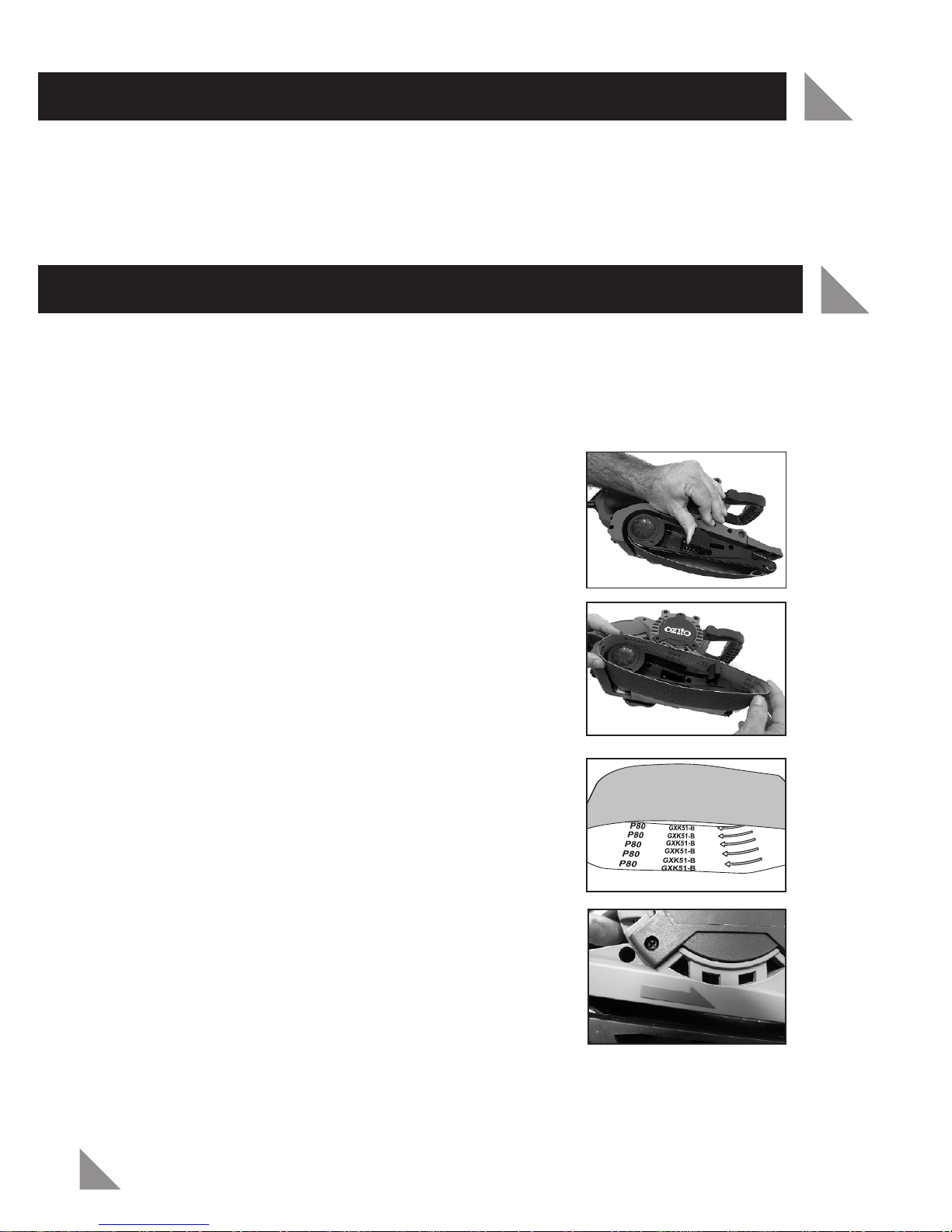

Properly adjust tracking of belt to avoid it overhanging the housing.

A running belt overhanging its housing can cause severe lacerations.

Keep the cord to the side away from pulleys. The cord can be dragged into the

belt housing and become entangled with the pulleys.

Warning! Some dust created by power sanding, sawing, grinding, drilling and other

construction activities contain chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically treated timber

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area and

work with approved safety equipment, such as dust masks that are specially designed

to filter out microscopic particles.

!

!