6

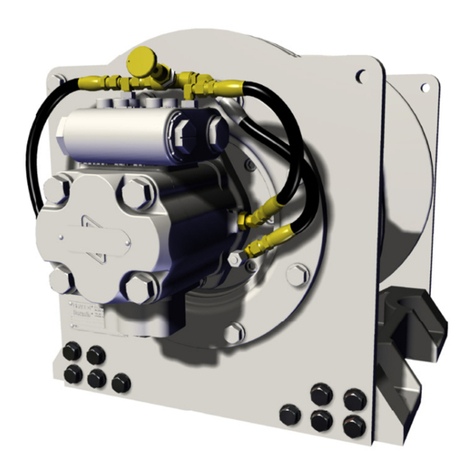

bolt access cover. Remove the cover, locate the spin-on

pressure filter and remove the filter element with a strap

wrench.

Lubricate the filter gasket and adapter threads with winch

oil and install new filter element onto filter head. Tighten

½ - ¾ turn after seal ring makes contact with filter head.

Start tractor and operate engine at low idle. Correct any

leaks.

The filter bypass indicator light may come on for a short

time during initial cold start-up but should go out as the oil

warms up. If the light stays on, this indicates a restricted

filter element, sending unit stuck in the bypass position or

accidentally grounded sending unit wire.

3. Control Cable and Pressure Adjustment

While the access cover is removed, it is advisable to

check control cable adjustment and hydraulic main relief

pressure. Place the Power Shift control lever in the cen-

ter “Brake-On” (neutral) position. Install the yoke pins into

the cable yokes/control valve spools and secure with

hitch pins. The yoke pins should slip easily into the bores

without any binding. The control valve spools are spring

centered. If you notice any binding, turn the cable

adjusters in or out until you obtain a “free pin” condition.

Make certain accumulator stored oil supply has been dis-

charged as described earlier. Install an accurate 0-600

psi (0-4137 kPa) gauge onto the – 4 J.I.C. gauge port

next to the control cables. Start tractor and operate

engine at approximately 800-1000 RPM until pressure

stabilizes. Maximum pressure during “charging” mode

should peak at 400 psi (2758 kPa). Pressure will slowly

fall back approximately 15-20% from the relief setting

then quickly return to 400 psi (2758 kPa) when the valve

cycles.

If adjustment is required, locate the adjustment screw

hole behind port “P” of the control valve. With a ¼ in.Allen

key, loosen the outer lock screw. Insert a 3/16 in. Allen

key through the lock screw and turn the adjusting screw

clockwise to increase peak pressure; counterclockwise to

decrease peak pressure. Tighten the lock screw.

TIP: It may be helpful to place the controls in

Brake-Off to use some oil in the control circuit and

cause the valve to slowly “cycle” so that peak pres-

sure may be more easily observed.

Stop engine, discharge accumulator stored oil supply as

described earlier and move hydraulic gauge to the “B”

test port on the brake housing. A ¼ in. NPT adapter will

be required.

Start tractor and operate engine at approximately 800-

1000 RPM. Place Power Shift lever in the Brake-Off posi-

tion and observe BRAKE-RELEASE oil pressure. Loosen

cable adjuster or cable yoke jam-nut and adjust brake

control cable to achieve approximately 300 PSI BRAKE-

RELEASE pressure.

Stand away from service access of winch and return

Power Shift lever to the BRAKE-ON (neutral) position.

BRAKE RELEASE pressure must return to 0 with the

controls in BRAKE-ON (neutral) position.

TIP: Optimum BRAKE-RELEASE pressure is the

highest pressure you can achieve while ensuring

pressure ALWAYS drops to 0 when controls are

returned to BRAKE-ON. Excessive heat and accel-

erated brake and hydraulic component wear will

result if BRAKE-RELEASE pressure does not

return to 0.

With control in Brake-On (neutral) remove gauge from “B”

port and securely install plug into brake housing.

Discharge accumulator stored oil supply as described

earlier. Remove pressure filter element to gain access to

accumulator. Install gauge assembly to accumulator and

observe pressure. Recharge unit to 190-210 psi (1310-

1448 kPa) with dry nitrogen. If the accumulator will not

hold a gas charge, then the unit should be replaced by

the spring/piston type accumulator. Order kit P/N 62138,

reference Carco Service Bulletin 95. The spring/piston

accumulator requires no periodic service.

Reinstall the filter element as described earlier.

Install access cover plate and tighten eight ½ in. cap-

screws/nuts to 75 lb•ft. (102 N•m) torque.

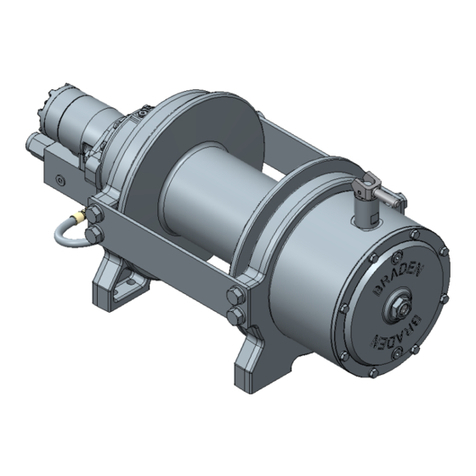

4. Vent Plug

The vent is located next to the power shift control harness

on all 50B & 70A model winches. It is very important to

keep this vent clean and unobstructed. Whenever the oil

is changed, remove vent plug, clean in safety solvent and

reinstall. Do not replace with a solid plug.

5. PTO Shaft

Winches adapted to J.I. Case, John Deere and Komatsu

powershift tractors are driven by a long, automotive-type

driveline PTO shaft.

The PTO shaft u-joints, slip-joint, flanges and fasteners

must be inspected, tightened and lubricated as required

at least once every three months or 500 tractor hours,

whichever occurs first.

Inadequate PTO shaft maintenance may result in the

accelerated wear of the PTO shaft, U-joint, bearings and

the adapter gear box components.