5

3. Assure that personnel responsible for hand signals

are clearly visible and that the signals are thoroughly

understood by everyone.

4. Inspect winch cable, rigging, winch and tractor at the

beginning of each work shift. Defects should be cor-

rected immediately.

5. Position tractor for straightest line of pull to reduce

wear on winch cable and ensure even spooling.

6. When winding winch cable on the winch drum, never

attempt to maintain tension by allowing winch cable

to slip through hands. Always use hand-over-hand

technique, being careful to keep hands and clothing

away from winch drum and fairlead rollers.

7. Be sure of tractor ground stability before winching in

a load.

8. Store unused chokers, slings, and rigging in a neat

and orderly fashion to prevent damage to equipment

or injury to personnel.

9. Do not operate the winch under loads that exceed the

maximum rated bare drum line pull. For excessive

loads, use a multipart line and sheave blocks. Any

attempt to exceed the capacity of one winch (such as

coupling two or more tractors together) is extremely

hazardous.

10. The factory-approved adaptions for CARCO winches

are designed and intended for use on specific mod-

els of crawler tractors. Changing winches between

trac- tors is not possible in some cases because of

differ- ences in tractor models. Some changes cannot

be approved by CARCO because of safety limitations.

Call a CARCO dealer or the CARCO factory prior to

attempting winch modifications or before mounting on

a different tractor.

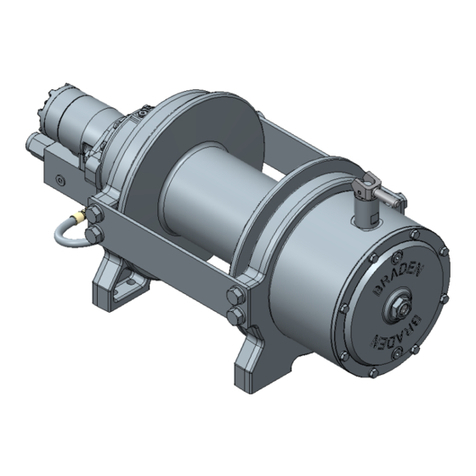

11. CARCO H Series winches are powered by the trac-

tor hydraulic system. Discharge all retained hydraulic

system pressure before removing any hydraulic lines

or fittings. Personal injury may result from sudden

release of oil pressure.

12. To discharge the winch control system pressure, stop

the engine and cycle the winch control lever(s) into

all positions five times. Refer to the tractor manufac-

turer’s service manual for additional information.

13. On machines having hydraulically, mechanically and/

or cable controlled equipment, be certain the equip-

ment is either lowered to the ground or blocked

securely before servicing, adjusting, and/or repairing

the winch. Always apply tractor parking brakes and

lower equipment before dismounting the tractor.

14. The winches described in this manual are neither

designed nor intended for use with or application to

equipment used in the lifting or moving of persons.

15. Install guarding to prevent personnel from getting any

part of their body or clothing caught at a point where

the cable is wrapped onto the drum or drawn through

fairlead guide rollers.

16. Keep equipment in good operating condition. Perform

scheduled servicing and adjustments listed in the

Preventive Maintenance section of this manual. Use

recommended lubricants.

17. An equipment warm-up procedure is recommended

for all start-ups and essential at ambient temperatures

below +40ºF (5ºC). Refer to Warm-up Procedure

listed in the Preventive Maintenance section of this

manual.

18. Never exceed 4 mph (6.4 km/hour) relative speed be-

tween the tractor and the load while in DRIVE-AWAY

mode. This relative limit applies when the tractor and/

or the load are moving. Limiting the tractor to either

rst or second gear typically prevents reaching ex-

cessive speed only when the tractor is moving. If the

load and the tractor are moving, tractor and/or load

speed must be reduced so that relative speed does

not exceed the speed limit. Exceeding this relative

speed limit will cause the part of the winch power train

connected in DRIVE-AWAY to reach damaging back-

driven rotational speed and cause catastrophic winch

failure, damage to property connected to winch, other

property damage, personal injury, or death.

19. Drive-away should never be used with a suspended

load, such as lowering heavy equipment down a hill.

Always use the reel-out function of the winch to lower

a load.

20. The correct drum wire rope capacity (length) and

diameter are detailed in Service Bulletin Number

LIT2435 for CARCO Winches, and LIT2436 for Cat-

erpillar Winches.

21. Do not exceed the rated drum wire rope capacity of

the winch. Never use a larger wire rope diameter than

specied. Using too long of wire rope, or the wrong

size, can place excessive loads on the winch drum

and gear train. The length of tail chains, chokers, and

other end rigging count toward the maximum allow-

able rope length, so if such equipment is used, the

rope length must be adjusted accordingly.

22. Never operate the winch with the wire rope on a higher

layer than recommended. Never operate winch with

the wire rope outside the drum ange.

GENERAL SAFETY RECOMMENDATIONS