System Operations Manual

www.paceworldwide.com Page 5 of 40

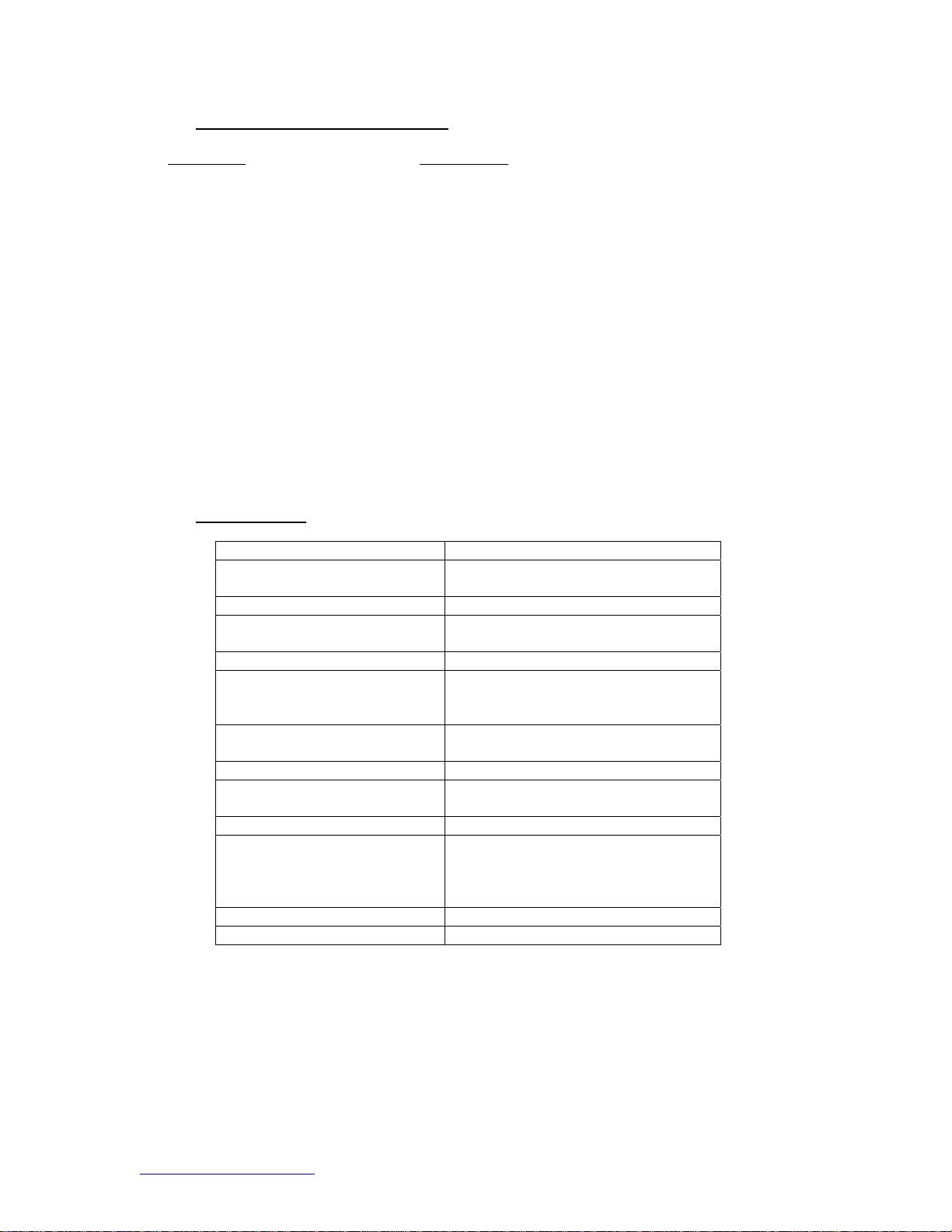

G. Optics Housing Contains the camera and beam splitter (prism). The

housing is retractable and should be kept in the retracted

position when not in use. The lights for the optics will

turn on/off automatically when the housing is

extended/retracted.

H. Bottom Side Heater Used to warm the PCB from the underside. It is an IR

type heating source.

I. Board Holder The board holder is fully adjustable in the X direction

only. Fine adjustment of both the X and Y direction is

achieved by using the adjusting knobs on the end of the

holder for X and on the front of the machine for Y.

The right side of the holder is spring loaded to hold the

PCB securely.

J. On / Off Switch Used to turn the system on or off. When turning off the

system, always turn off the PC using the windows

interface first.

K. Mouse Used to enter information into software.

L. Emergency Off Switch In case an emergency shut down is necessary, press

this button.

3. Safety Information

a. Do not contact the Heater or its peripheral parts during operation.

b. Once turned off, let the unit cool completely before contacting.

c. When using fluxes, use fume extraction equipment or use in a well-ventilated

area to minimize operator exposure to fumes.

d. Do not use near combustible vapors.

e. Do not leave the equipment unattended when in use.

f. Do not open rear panel without disconnecting power cable.

4. Features

a. The TF 1500 is ideal for post assembly rework, repair, and low volume/short run

production operations. The TF 1500 can remove and install PBGAs, CSPs, FCs,

LGAs, LCC’s and other SMDs.

b. Featuring unparalleled thermal performance, The TF 1500’s flexibility and state

of the art process software means no other system is easier to use. The TF 1500

is a PC driven, semi-automated system that requires a Pentium ® 4 PC featuring

Windows XP® Professional OS. The unique standard software package offers

much more than just an operator interface. TF 1500’s advanced vision and

placement system is highly accurate and can quickly magnify even the smallest

components for easy alignment. TF 1500 uses a combination of convective top

heating coupled with powerful IR bottom heating for an effective, repeatable

heating process.

c. Economical and easy to use, the TF1500 Rework System delivers high-end

BGA/CSP functionality, moving far beyond expensive, bulky rework machines by

offering unparalleled performance at an affordable price.

d. REFLOW FUNCTION

i. Unequalled programmability and process control ensures successful,

repeatable installation.

ii. The powerful and responsive 1600 Watt top heater, with closed loop

temperature control, coupled with proven TF 3000 nozzle design ensures

uniform temperature distribution when heating.