Page 1

1. Summary

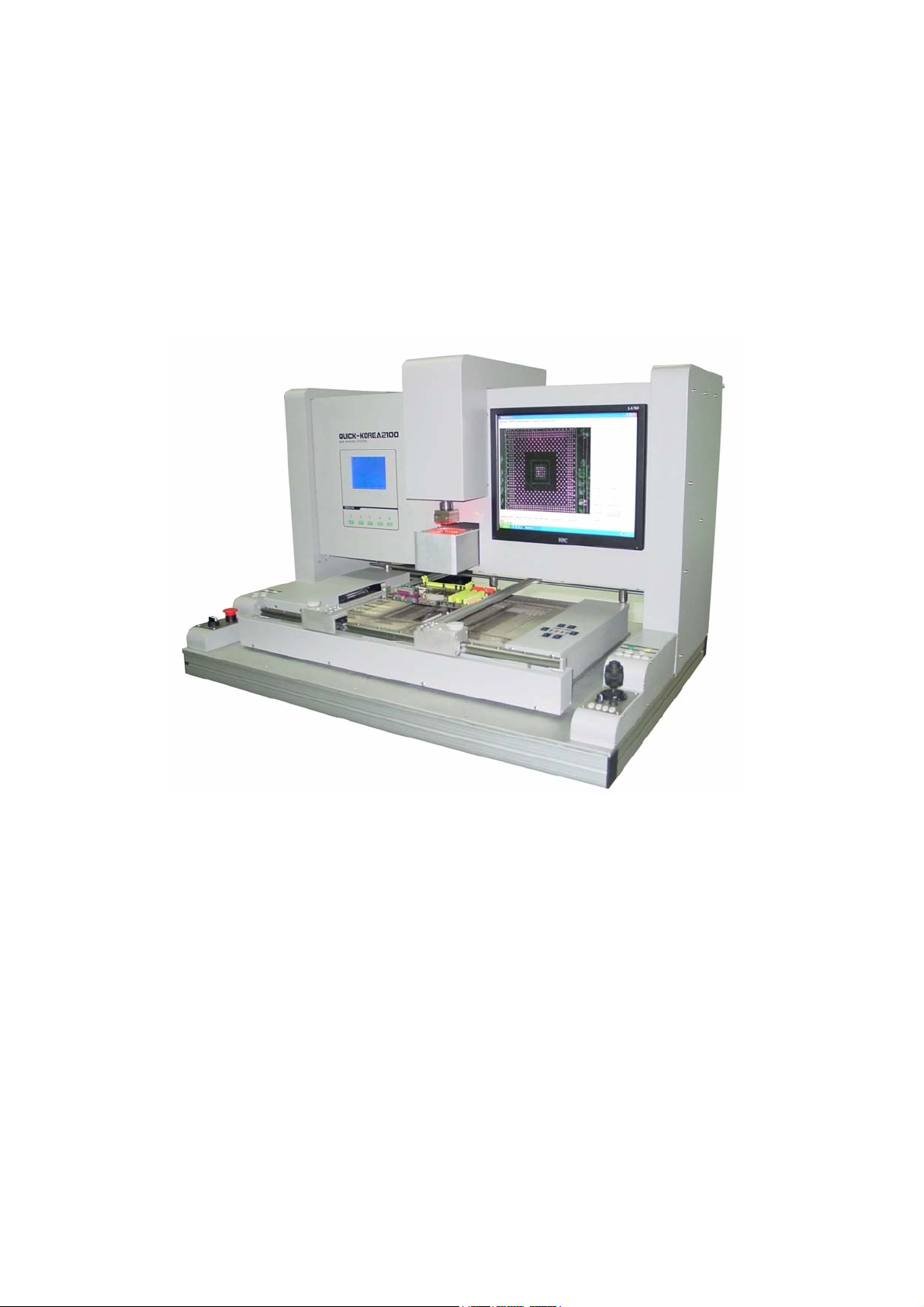

Thank you for using QUICK BGA2100 Rework System. This system, which adopts microprocessor control to

solder and de-solder the surface mount components safely and accurately. It also can control the whole technical

process and record all the information by means of the BGA Software, thus satisfying the higher technical

demands of modern electronic industry. It is one of the most valued electronic equipments in electronic field.

QUICK BGA2100 Rework System adopts hot airflow technology and closed–loop principle, integrating

harmoniously the infrared preheater and the sirocco heater together. In order to control the soldering process

optimally and get the nondestructive and reproductive PCB temperature, QUICK BGA2100’s heating power is up

to 5000W and the heating power can be adjustable.

With K-type sensor controls the surface temperature of the BGA. For more preciseness technics demands and

effectual controlling the PCB temperature and the encapsulation temperature, the technology of re-flow soldering

controlled by closed-loop ensures the precise and smaller technical window, even heat distribution and appropriate

peak value of temperature for lead-free soldering. Besides, the infrared preheater is suitable for all applications,

such as large or small PCB and lead-free solder, moving automatically in X-axis to heating the PCB evenly.

QUICK BGA2100 Rework System with 60*60mm optics aligning prism, big BGA alignment can see clearly and

the aligning lens are controlled by the step motor and the chip slave is above the lens. The PCB fixture is square

and the maximum size is 550*450mm, the width of the left and right arms can be adjusted and the abnormity

knightheads can be fixed on the arms. And the bottom knighthead is connecting with the arm to keep identical

placing position of PCB.

For reducing the manual effects, QUICK2025 BGA rework system can automatically run the processes except

adjusting X、Y、θ with hand, but with the precise motor for precise alignment. Besides, the chip sucking and

pasting, lens moving, reflow controlling, heating moving and chip de-solder are all automatic controlled by the

step motor. And the system has the controlling software with wide screen display of LCD to multi-control the

processes unaided or by the outer computer.

The new BGA rework system has the advantages of the infrared heater and sirocco heater, satisfying the demands

of reworking the BGA, especially in lead-free soldering.

2. Specifications and Technical Parameters

2.1 Specifications

1. power: 5000W(max)

2. Voltage: 220V/230VAC 50/60HZ

3. PoweroftopHeater: 800W

4. Power of Bottom infrared preheater: 400W*8=3200W

5. Power of Bottom Sirocco Heater 800W

6. airflow speed of the left side cooling fan:≤3.5 m3/min

7. temperature of the Sirocco Heater: 500℃(MAX)

8. temperature of the infrared heater: 500℃(MAX)

9. size of the infrared heater:550mm*450mm

10. Maximal PCB size: 600mm*500mm

11. chip size range:2*2mm~60*60mm