FLOOR SANDING TECHNIQUE

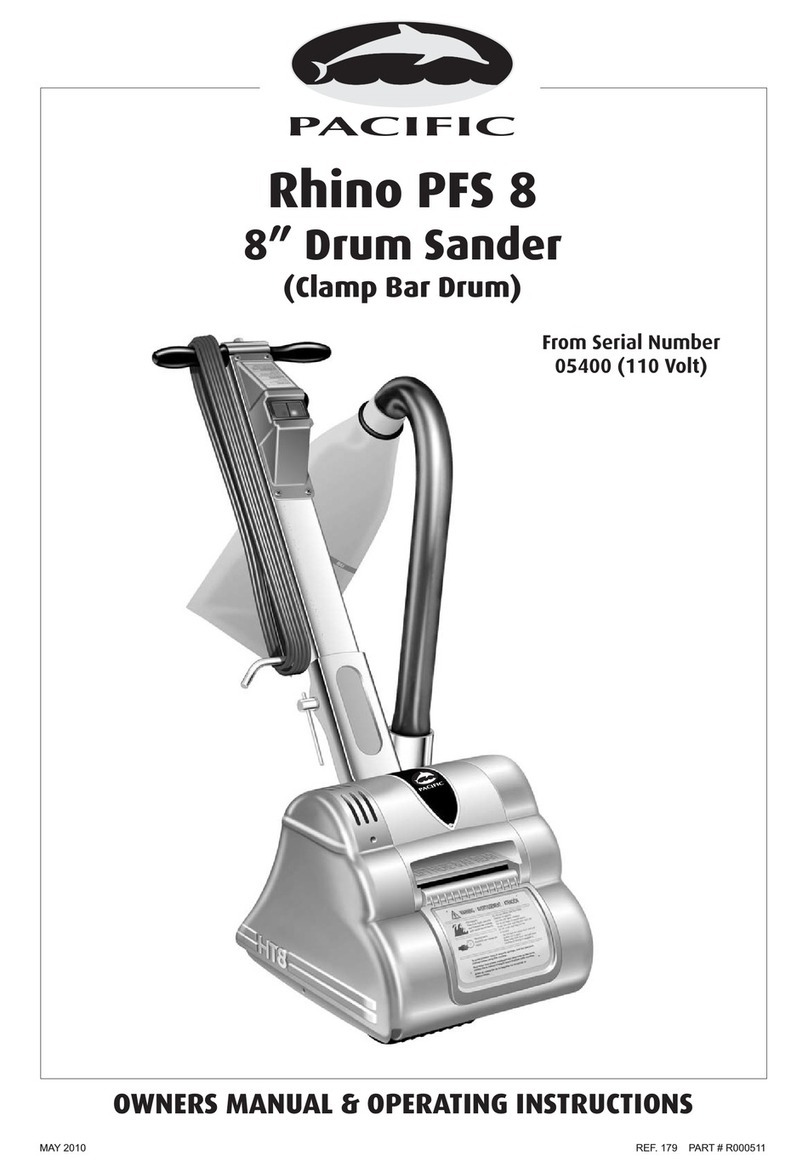

Pacific Rhino PFS 8 Drum Sander

Pacific Wolverine Edger Sander

Hand Sanding

- a powerful floor

sander designed for the rapid leveling and sanding of

all types of wood flooring excluding thin laminated or

veneered floors. Load the sander with abrasive

making sure that it is skin tight around the drum.

Loose sheets will tear. Place the sander on the right

hand wall (unless you are making an angled cut on

uneven floors) with about two thirds of the floor in

front of you. Start the sander with the drum off the

floor then walk forward at an even pace and ease the

drum on to the floor. As you near the end of the pass,

gradually raise the drum off the floor. Practice this

technique before turning on the sander.

Cover the same path you made on the forward cut by

pulling the machine backwards and easing the drum

to the floor as you begin the backward pass until you

reach the original starting point, then ease the drum

off the floor.

When two thirds of the floor is sanded, turn the floor

sander around and sand the remaining third in the

same way. Overlap the one third area by 0.6 to 0.9

meters (2 to 3 feet ) with the two thirds area to blend

the two areas together.

- a powerful disc

floor sander designed for sanding along the edges of

a floor without damaging the baseboards or

moldings. Also suitable for smaller areas where the

HT8-1.2 Floor Sander will not reach like stair treads

and closets load the abrasive disc making sure the

retaining bolt is tight. Start the edger with the disc off

the floor then lower the disc to the floor as you move

the sander. Work progressively moving the sander in

a sweeping motion from side to side.

- to sand difficult to reach areas

scrape and sand the floor by hand. Use a scraper to

remove old finishes, always scraping in the direction

of the grain, and then sand by hand using the same

grit abrasive as you finished with when machine

sanding. See Floor Sanding Technique diagrams on

page 5.

WARNING - never bounce the sanding

drum or dwell in one place as this will

sand dips and hollows in the floor.

FLOOR TYPES

PLANK & STRIP FLOORS

PARQUET & BLOCK FLOORS

Old floors in good condition

Uneven floors

Floors with an existing finish

- when the floor is in

good condition - no uneven edges, cupping or

crowning of planks and strips - and you want to re-

surface the floor, sanding back to new wood, start

sanding in the direction of the planks or strips - with

the wood grain. Start with a grit abrasive.

Complete the first cut with the Pacific Rhino PFS 8

Drum Sander then sand up to the baseboards and

door thresholds with the Pacific Wolverine Edger,

using a grit abrasive, blending the edges in

with the main floor area. Sweep the floor. Using a

grit abrasive, sand the main floor area

with the drum sander and then complete the floor with

the edger using a grit abrasive. Sweep the floor.

Finish sanding the main floor area with the drum floor

sander using a grit abrasive.

- when the floor is uneven sand

diagonally at 45 across the room in both directions

using the Pacific Rhino PFS 8 Drum Sander with a

coarse grit abrasive. Only make one cut on both

diagonals, this will achieve a basic level. Now

complete the floor as for a level strip or plank floor.

Use the same grit abrasive as was used on the 45 cut

for the first cut parallel to the planks or strips.

- when re-finishing a

floor remove as little of the existing surface as

possible. If the floor is badly marked and scratched

and has to be sanded back to new wood use the

Pacific Rhino PFS 8 Drum Sander and Pacific

Wolverine Edger Sander. Always try a medium grit

paper first, particularly on a diagonal cut. If 90% of

the old finish is removed and the floor is generally

leveled, you do not need to use a coarse grit abrasive.

The grain of the wood will run in a number of

directions so sand the floor in the direction of the

main source of natural light in the room. If there is no

source of natural light sand in the direction of the

longest side of the room or, if the room is square, in

the direction the furniture is laid out and how people

normally use and view the room.

This technique will help mask any imperfections in the

floor. Complete the sanding operation as detailed

for plank or strip floors.

medium

medium

fine

fine

medium/fine

o

o

4