Paitec ES3000 User manual

ES3000

USER

MAN

UAL

Pressure

sealer

This manual provides detailed information on how to operate and maintain your ES3000.

Please

read this manual before operating the machine in order to prevent any damage

caused by improper handling

.

Rev. 11

-

06

-

17

Introduction

- 2

-

Thank you for purchasing Paitec USA products

Copyright

Any of the contents should not be copied, re-printed or translated by

ot

he

r

Languages without approval by Paitec U

SA

ES3000 is the registered trademark of Paitec USA.

- 3

-

Contents

1. ES3000

Specification

---------------------------------------------

4

2. Identifying the Parts

---------------------------------------------

5 ~ 6

3. Unpacking

----------------------------------------------

7

4. How to install the Folding Cassette

----------------------------

8

5. Folding

Cassette

Setting Guide

--------------------------------

9

6. OP Panel Guide

----------------------------------------------

10~14

7. Handling of the forms before using

---------------------------

15

8. Paper

J

am removal

---------------------------------------------

16

9. Handling the error

message

-----------------------------------------

1

7

10. Operator Maintenance

--------------------------------------------

18

- 4

-

ES

3000

Fe

at

ures

ES3000

Features

(Pressure

Sealer)

• Perfect Sealing Quality & Low Noise Level

The most advanced pressure sealing technology with lightweight, excellent sealing quality

and extremely low noise levels.

• Excellent Folding Quality

Excellent folding quality, even with plain paper based on our advanced technology.

• Compact & Dynamic Design

Advanced technology sealing system allows for compact design which saves valuable

workspace.

• Angle Seal Technology

Innovative and exclusive angled seal technology provides superior sealing capabilities.

ES3000 Specification

• Form Size: A4 / Letter / Legal size

• Speed: 3,000 forms / hour

• Input Tray: up to 150 forms

• Form weight: 60-120gsm

• Folding Setting: Z, C, V & Double, 14” uneven Z

• Manual Feed

• Batch Counter

• Noise Level: less than 45db

• Weight: 22kg

• Dimension: 320 X 390 X 280mm (W x L x H)

*Based on 80gsm paper weight.

- 5

-

Identifying

Par

t

s

Fold

adj

u

st

men

t

Kn

ob

③1st

Foldin

g

Casse

tte

⑦

Ou

tpu

t

Fold

adj

u

st

men

t

Kn

ob

①

Pa

p

er

In

-

feed

gu

i

de

④Fold

Roll

er

cover

⑤OP

p

an

el

③2nd

Fold

Casse

tte

⑥Power

S

wi

tch

②Power

S

ocket

- 6

-

1

st

Identifying

Par

t

s

1 Paper Guide

Load the paper into the paper hopper, making sure the paper in-feed guides are near

touching each side of the paper to guide paper squarely.

(Prepare paper by making edges neat before loading)

2 Power Socket

Main power socket located on the back of the machine

3 & 2nd Folding Cassette

1st folding is Insert into the 1st folding cassette in front , 2nd folding is Insert into the 2nd

folding cassette in rear.

4 Roller cover

Open roller cover when jam occurs.

(Please turn the Knob in clockwise rotation for unlock).

5 OP panel for

St

art

/

St

op & other function

6 Power

s

wi

t

ch

After check power socket, please turn on/off power switch

7 Output

Finished forms exit the front of the machine

[Side View] [Rear View]

- 7

-

Unpacking the Machine

Contents

Please check the following parts are included in the box.

Power cable, 1ST Fold Cassette, 2nd Fold Cassette, Output stacker User manual

[Box open] [1st, 2nd

Cassette

& Power cable

*

Caut

i

on

Power connection: Please refer to the

label for electric information which is

located at the back of the machine. If it is

not working properly, please contact your

local dealer for service.

[Remove Safety Tape]

- 8

-

How to install the Folding Cassette

Adjusting the Fold

Ca

ss

et

t

e

Insert the 1st

C

ass

e

tt

e

(Pic.

1) in the front and 2nd Cassettein the

rear.

(Pic. 2) turn the Knob to adjust the fold cassette to the desired paper size (Refer

to fold assist label on top of the in-feed tray.)

[Pic.1: 1st

Fold Cassette

Insert] [Pic 2: 2nd Fold Cassette

Insert

]

[Pic 3: Adjust 1st Fold size] [Pic 4: Adjust 2nd

Fold

size

]

- 9

-

Folding CassetteSetting Guide

Folding

Cassette

Setting Guide

How to set

“

Z

-

F

ol

d

”

•Swivel the Knob to counter clockwise and move on

99

mm

.

•Swivel the Knob to clockwise to tighten and hold the

p

osi

ti

on

.

•2nd Cassetteis same as 1st

C

assette

.

! Attention: “C-Fold” is required to use 270mm

Cassette

(Pic. 3

)

[Pic.1

:

Standard 1st

Cassette] [Pic.

2

:

Standard 2nd Cassette]

[Pic.

3

:

Option – 270mm

Cas

sette]

- 10

-

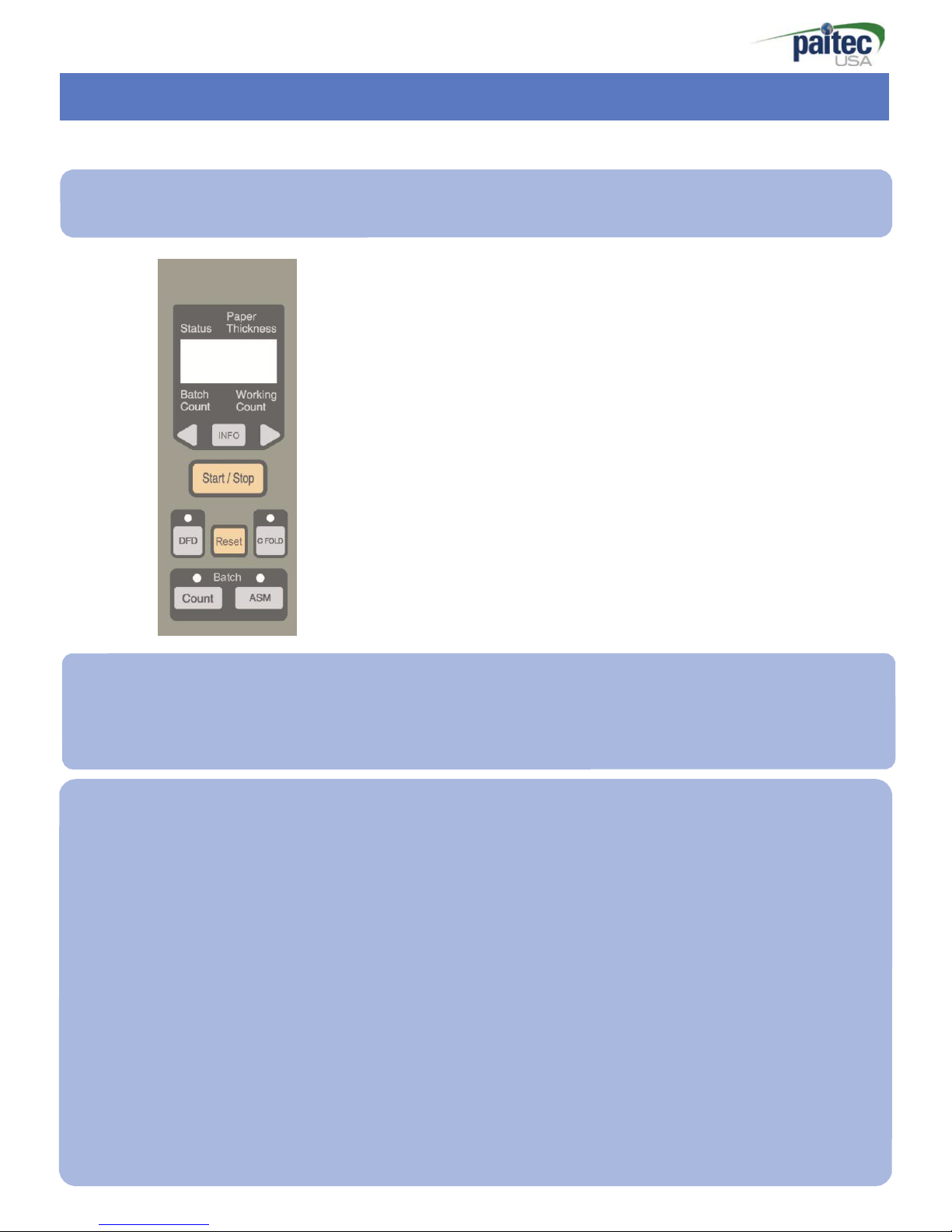

OP panel Guide-1

Operation Panel

S

ta

r

t/

S

to

p

Please

push a

[

St

art

/

St

op

]

button for operating the machine on the general

op

era

ti

on

.

If the [Start/Stop] button is clicked one time the machine will be

op

era

ted

.

And

[Sta

rt/Stop]

is clicked once more, the machine is

stopp

ed

.

Reset

[Reset]: Initialize the working counter & paper thickness

.

•General

M

od

e

[Reset]: working count is 0 and paper thickness is initialized with 1 digit based on DF/PT

level.

• Batch

mod

e

[Reset]: batch counter 0 and paper thickness is

i

n

i

ti

al

i

z

e

d

,

but working count is

not

initi

al

i

z

ed

.

•C-fold mode (270mm

Cassette

required for C-fold: Option)

[Reset]: working count 0 and paper thickness is initialized with 1 digit based on DF/

P

F

level. (working count light

off)

- 11

-

OP Panel Guide-2

C Fold - ON/OFF

This button is for C fold mode.

Beeper sound when it is settled C-fold mode and working count light is

o

ff.

If you want to cancel for C

Fol

d

,

please push [C fold] button again.

DFD (Double Feed Detection) o

n/

o

ff

If you do not want to use double detection

fun

c

ti

on

,

you can make “DF mode” Off.

Press

[DFD] and see disappearing “paper thick” on LCD.

Note: this function will not work well if your form are too dark or too many black ink on the

forms.

DFD Sensibility

DFD sensibility sometimes has to be changed for better

d

etec

ti

on

.

y

Note: Press and hold down [DFD] button, change the "paper thick" value by using the [Direction]

button then save it by hold down the [DFD] button again.

Batch Mode ON/OFF

Press

[Count] button for activating the batch count

fun

c

ti

on

.

Press [Count] button once

again for deactivating the

fun

c

ti

on

.

Adjust Batch Count

The batch count adjusting menu is appeared through holding the [count]

b

utt

on

.

You can change the value by using the [Direction] buttons and confirm the count

b

y

holding the [Count] button again.

Auto Start Mode (ASM) ON/OFF

Press

[ASM] button activate the auto start mode (ASM). Press [ASM] button once again

the ASM is turned off.

The batch mode is operated continuously if the ASM is activated and the interval of each

batch work is 3 seconds.

- 12

-

OP Panel Guide-3

INFORMATION

M

enu

The information menu is appeared when the [INFO] button is pressed on the ready state.

1) What is the “Information‟ menu?

In this menu, a couple of information about the machine is showed

.

And user can check for several settings and information about the setup

.

2) Menu

a) Total Count

:

The total count of the ma

c

hi

ne

b) Paper Thickness

:

The sensitivity of the DFD

c) Firmware Version

d) Installation Date

:

The date when the machine was

i

nst

al

l

ed

.

e) Total Usage Time

:

Measure the using

ti

me.

f) Batch Count

:

The number of the batch

mo

de

.

For moving back to the ready state, press the [INFO] button again.

- 13

-

OP panel Guide

-

4

1.

[

St

ar

t

/

St

op

]

is clicked one time the machine starts to work and clicked once more

the

machine is stoppe

d.

2. If the [Reset] is clicked a Working Count becomes

„0‟

and Paper

Thickness

is

ini

ti

al

i

z

ed

.

R

e

ad

y

7

0

[Ready

s

t

at

e

]

Work 13

6

[Work

s

t

at

e

]

[Paper thickness]

[Working

count]

Batch Count

Mod

e

1. Check the

„

Re

ad

y

Stat

e

‟

of the OP

P

ane

l

.

2. Adjust the fold-position of the 1st and 2nd

CST

by using the setting guide of the

fold

-

position[Page 11].

3.

Press

the [Count] button and check the

LED

is turned

on

.

3. To hold down the [Count] button shows

„Batch

count setting

„

when the

„Batch

mode‟is

ac

ti

va

ted

.

The number of batch count can be changed [from 1 to 200] every time

the

[Direction] buttons are

pr

essed

.

The count will moving faster if hold down

[

Dir

ecti

on

]

4. Hold down the [Count] button for saving the

c

ou

nt.

Ba

tc

h

Set 10

[Count

s

e

tt

i

ng]

Ready 7

B10 0

[Batch

s

e

t

]

- 14

-

OP panel

g

ui

de

-

5

J

o

b

Sep(Auto Start)

Mod

e

1. Check the

„Ready

State‟ of the OP Panel.

2. Adjust the fold-position of the 1st and 2nd

CST

by using the setting guide of the

fold

-

position[Page 11].

3.

Press

the [ASM] button after activating the „batch mode‟at the

fi

r

st

.

3. Check the

LED

lamp of ASM on the panel is turned

on

.

4. To press the [ASM] button once again for deactivating the ASM

op

ti

on

..

Ready 7

A10 0

[Batch mode + Job

Sep]

TIP. Batch +

J

o

b

Sep function

If the

„Batch

mode‟is using with

„J

ob

sep

‟,

batched working is operating continuously w

ith

3

-

sec

onds

-

i

nter

va

l

.

- 15

-

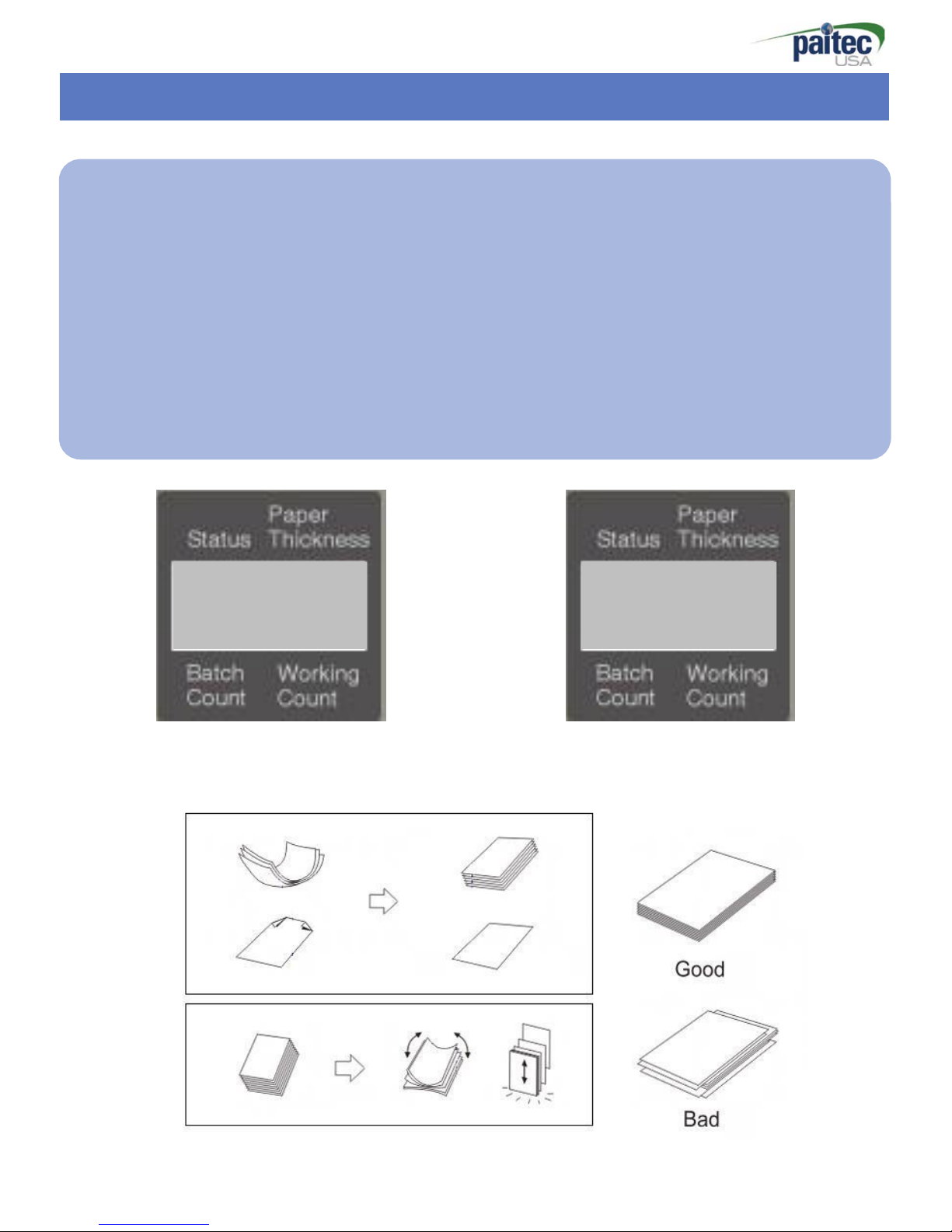

Handling of the forms before using.

TIP. Handling of the forms before using.

1.

Please

make the forms to well

-

ar

r

anged

.

2. The form has to be set on the paper tray

prop

erl

y

.

3. If too many sheets of form are set on the feed tray (over 150 sheets) it can create

feeding

prob

l

em.

4.

Please

check the fold-position by test-folding and adjust the fold-position

prop

erl

y

.

Do

ub

l

e

Fe

e

d

[Double feeding

det

e

ct

e

d]

Fe

e

d

J

am

[Feed jam

d

e

t

e

ct

e

d]

[Pressure

seal form handling before usin

g]

- 16

-

Paper

J

am Removal

Paper

J

a

m

Removal

The paper jam that is occurred in the Officemate 3D can be removed very

easi

l

y

.

The machine is stopped automatically when the paper jam is oc

c

urr

ed

.

And the paper

j

am

can be removed by using the jam removal

tool

.

The machine starts to operating when the

[

St

art

/

St

op

]

button is pressed after removing

the

jam.

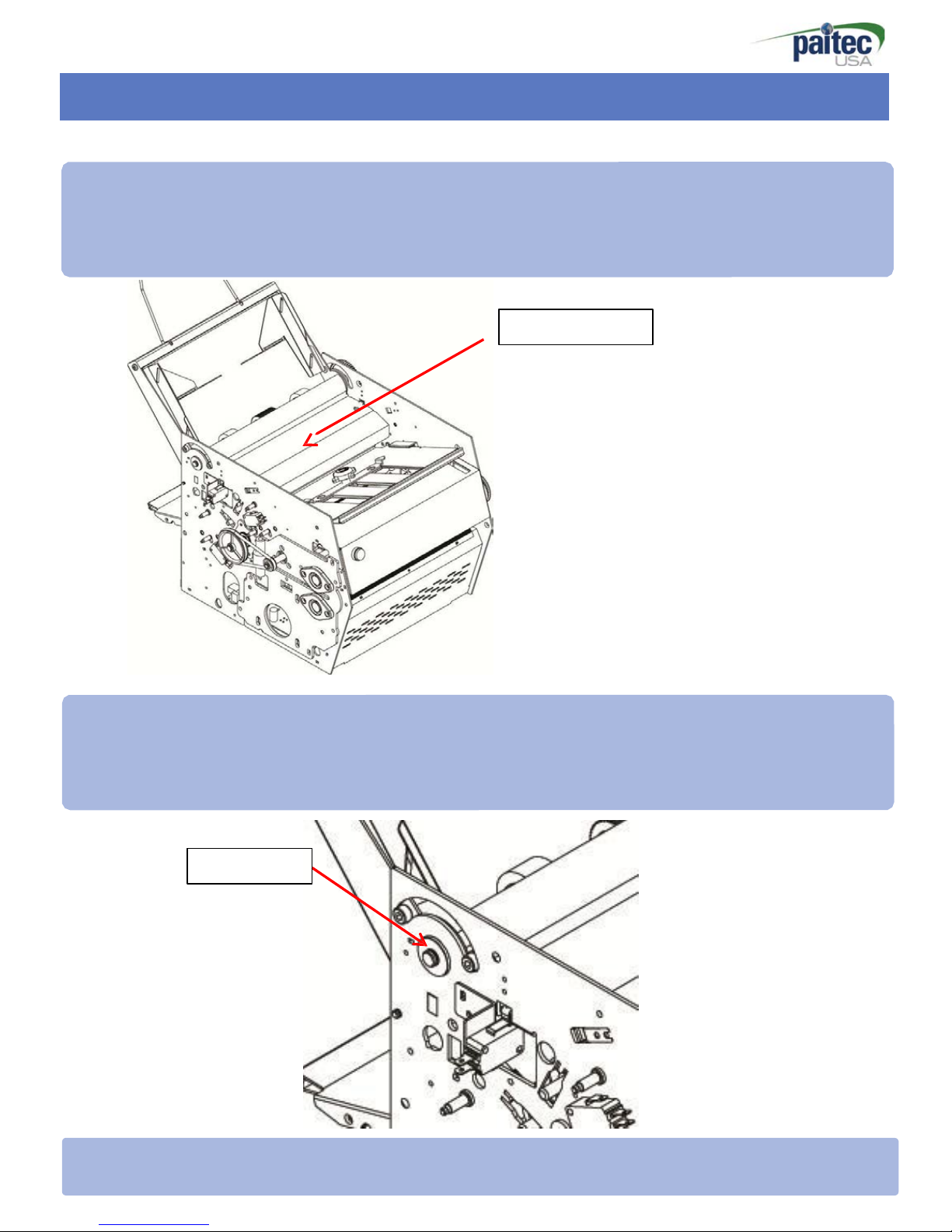

[Remove the 1st CST] [Open the top cover by un-locking

the

locking k

nob

.]

[Remove the jam by using the jam removal tool] [Insert the tool into the hole on the press

roller and rotate the press roller by hand]

! CAUTION:

Please

keep the jam removal tool to right position after removing the jam.

- 17

-

Handling the error me

ss

ages

Handling the error messages.

Do

ub

l

e

Fe

e

d

Fe

e

d

J

am

[Detect double feed

&

feed

j

am]

[Open the cover and

remove the jam]

1st CST

Open

[1st CassetteError]

[Check 1st Cassette]

2st CST

Open

[2nd CassetteError]

[Check 2nd Cassette]

- 18

-

Repairing and Replacement

Remove the

Cov

er

s

Remove the 4-screws for removing the

c

over

.

The Position of the screwsare pointed out in the pictures as

foll

ows

.

The other side cover is removed same way.

Caution :

Please assemble

the

covers

before operating the machine.

- 19

-

Repairing and Replacement

Replace the Feed roller

1. Remove the both cover

fi

r

st

l

y

.

And open the

„(1):Roller

C

over

‟.

(1)Roller Cover

Replace the Fold ro

lle

r

2. Remove the

„

(

2)

:B

us

hi

ng‟

.

(2)Bushing

For removing the

„(

2

):Bushing

‟

,

E

-

c

li

p

has to be

r

emoved

.

- 20

-

Repairing and Replacement

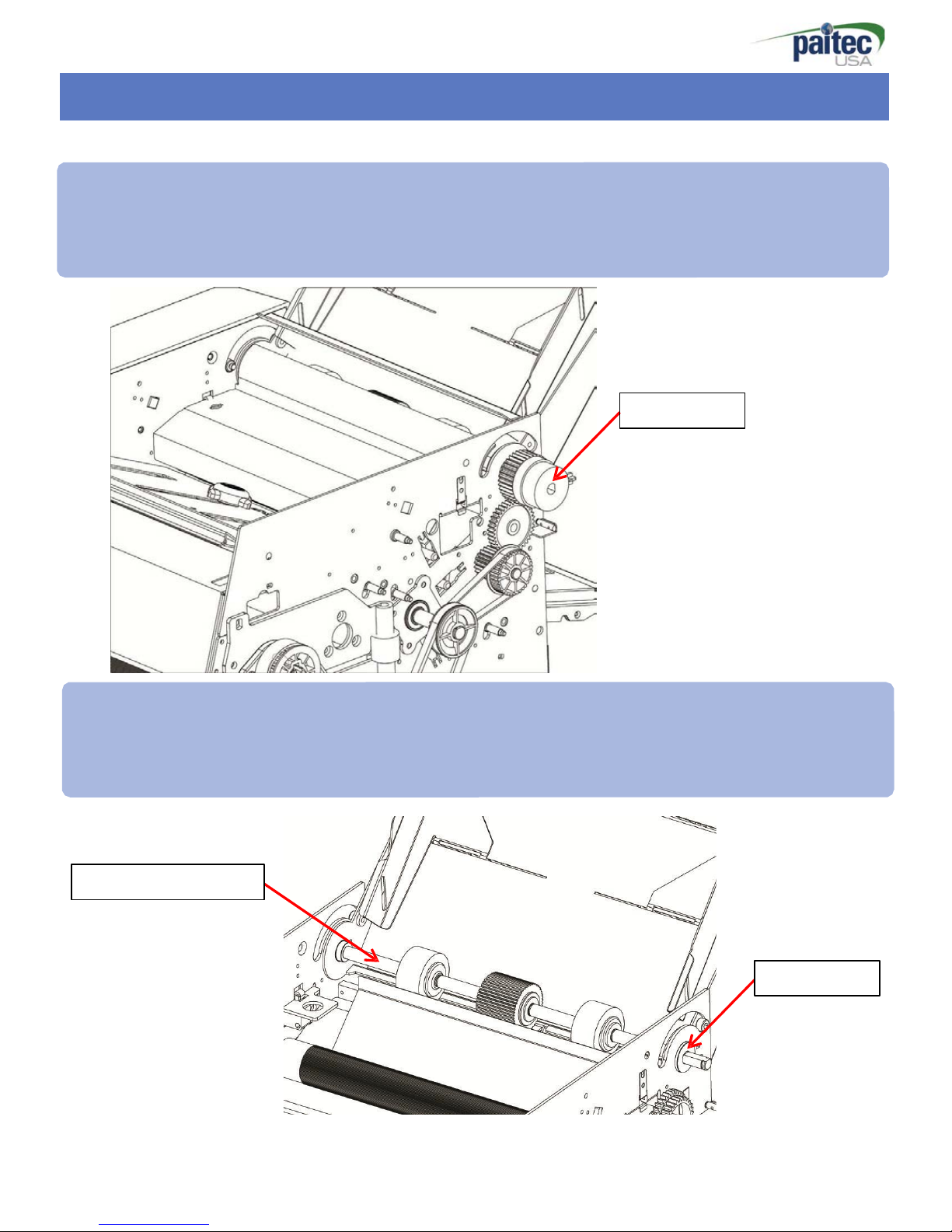

Replace the Feed roller

3. Remove the

„(3):Clutch‟.

(3) Clutch

Replace the Feed roller

4. Remove the

„

(

2)

:B

us

hi

ng‟

and

„(4)Feed

R

ol

l

e

r

:Ass

y

‟.

(4)Feed Roller:Assy

(2)Bushing

Re-assembling process has to be done by following the procedure to reverse.

Table of contents

Other Paitec Food Saver manuals

Paitec

Paitec MX-6000 User manual

Paitec

Paitec MX11000 User manual

Paitec

Paitec MX-13000 User manual

Paitec

Paitec ES8500 User manual

Paitec

Paitec MX17000 User manual

Paitec

Paitec ES5500 User manual

Paitec

Paitec ES2500 User manual

Paitec

Paitec IM8100 User manual

Paitec

Paitec MX-9000 User manual

Paitec

Paitec MX11500 User manual

Popular Food Saver manuals by other brands

Cleveland

Cleveland AFF-950 Specifications

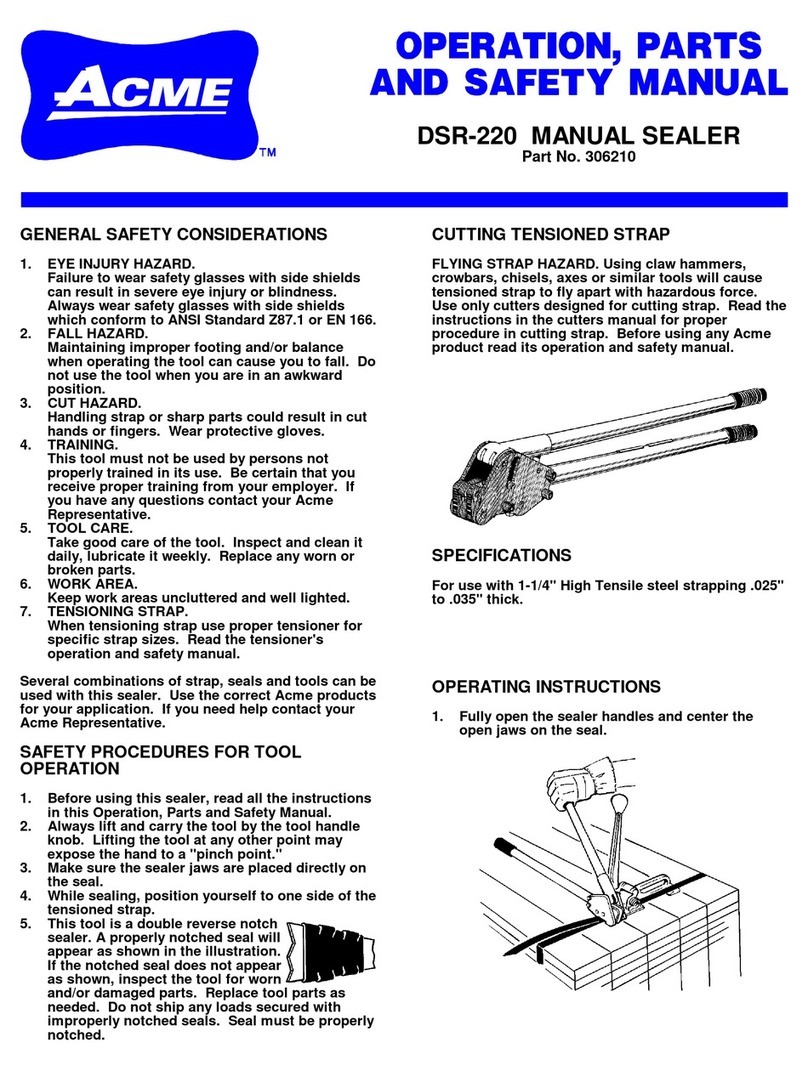

ACME

ACME DSR-220 Operation, parts and safety manual

3M

3M Matic 700r-s Instructions and parts list

Orgapack

Orgapack OR-V 41 P Operating and safety instructions

Signode

Signode RCN-3435 Operation, Safety and parts manual

Van Der Stahl

Van Der Stahl LOS NT Series operating instructions