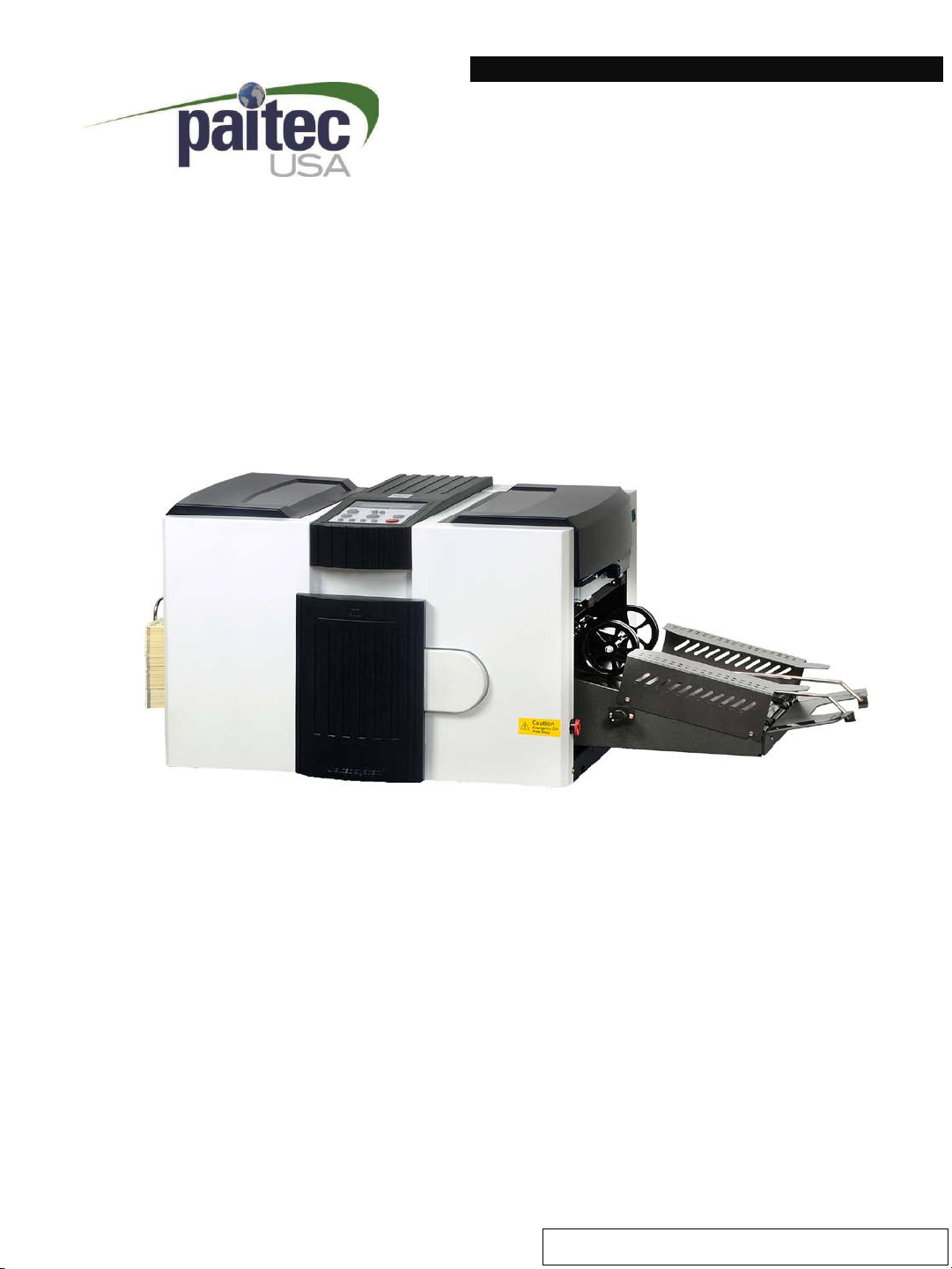

Paitec ES8500 User manual

Paitec USA-UM-ES8500_191206_EN_Rev.01

ES8500

User Manual

User Manual ES8500

Ver. 01

Introduction

Installation

1

Operation

OP Panel

8

Maintenance

Paper Jam

24

Introduction

2

Specifications

3

Identifying Parts

4

Contents

Installation

7

Paper Loading

10

Trouble Shooting

25

Understanding Folding Mechanism

13

Fold Type Setting

12

Operation

20

Cleaning

26

Functions

21

User Manual ES8500

Ver. 01

Introduction

Welcome!

Thank you very much for selecting our product!

This manual is prepared to provide you with guidelines on how to properly operate and

maintain the ES8500. Please read this user manual before operating in order to prevent

unexpected malfunction or damage. Please refer to the manual carefully and follow the

instruction.

Copyright

Any of the contents should not be copied, re-printed or translated by other languages

without Paitec USA approval.

Safety Precautions

Caution: Serious bodily injury or mechanical damage may result from

insufficient attention to or incorrect compliance with warning

messages using this symbol.

●Do not attempt to disassemble or reorganize the machine. It may cause an electric

shock or mechanical problem.

●Quickly disconnect the power if liquid or a foreign object enter the inside of the

machine.

●Do not enter metal or inflammable material into AC Inlet.

●Please contact local dealer when you relocate the machine.

●This manual is subject to be revised without notice for product improvement.

●Do not install the machine on the place as below.

- Near window or places exposed to direct sunlight.

- Where vibration is detected.

- Sudden temperature changes or poorly ventilated areas.

- Places exposed to hot or cold air directly. (not office circumstance)

- Not solid enough or weak floor.

2

Introduction

User Manual ES8500

Ver. 01

Specifications

Features

●ES8500 is a mid-volume pressure sealer. It features processing speed up to 9,000

forms per hour, perfect sealing quality with 2 metal seal rollers, with a monthly

duty cycle of up to 130,000 forms per month.

●ES8500 is Dual-Purpose(Stand alone or Optional In-Line kit), works equally well

as a stand-alone or in-line with laser printers a rear-exit paper path.

3

Specifications

Form Size A4 / Legal / Letter

Paper Weight 22#-28#

Speed Max 9,000 forms per hour

Fold Setting Manual

Fold Type Z, C, V, EZ

Double Feeding Detect Available by DFD sensor

Stacker Built-in 150 forms catch tray or Optional Conveyor

Duty 130,000 / month

Specifications

Introduction

User Manual ES8500

Ver. 01

Identifying Parts

4

Introduction

①Feeding Unit Safety Cover

②Upper Fold Cassette Safety Cover

③Lower Fold Cassette Door

④OP Panel

⑤Conveyor (optional)

Main Body

①②

③

④

⑤

User Manual ES8500

Ver. 01

5

Identifying Parts

Large Capacity Feed Table

Lower Fold Cassette

Upper Fold Cassette

①Feed Assist Hanger

②Feed Guide (Left)

③Feed Guide (Right)

④Locking Knob

⑤In-feed Roller

⑥Paper Detection Sensor

①Lower Cassette

②Stopper

③Stopper Adjustment Knob

④Stopper Locking Knob

①Stopper Adjustment Knob

②Stopper Locking Knob

③Fold Position Marker

④Fold Position Information

Introduction

④

①

②

③

⑤

④

①

②

③

①

③

②

④

⑥

User Manual ES8500

Ver. 01

6

Exit Side

①Power Switch

②Main Power Socket

③Conveyor Power Socket

④110~230V Switching Switch

⑤Emergency Switch

Identifying Parts

Introduction

①

②

③

⑤

④

Be careful when you change the 110~230V Switching Switch. If the

voltage selection is not correct, it may cause a damage on the machine.

User Manual ES8500

Ver. 01

Installation

7

Installation

Installation Environment

1. Input power : 100V / 230V (selected by 110~230V Switching Switch)

2. Machine size(mm) : 24” x 18” x 16” (without conveyor)

3. Machine weight : 115 Lbs.

- Weight of a product is heavy, please use appropriate table to support it.

- Please use grounded power cable.

Unpacking

Please check if all of the following parts are included in the box.

- Main body, Power Cord, User’s Manual, Jam Removal tool.

Removing Safety Tape and Styrofoam Location

Please remove all safety tapes and Styrofoam before operation.

Power Connection

Please refer to the label for electric information which is located at the back side

of the machine. When the power cable is properly connected, please switch the

machine on and check whether ‘Ready’ sign is shown on the display panel.

If not, please contact your local dealer for service.

User Manual ES8500

Ver. 01

8

Operation

OP Panel

Ready 10

9K 1240

①Mode: Machine setting and working condition.

②Speed: Variable speed (adjustable, 6K / 7K / 8K / 9K)

③Counter: Counter of current job.

④Total Counter: Counter of total operation.

OP Panel Display

1

User Manual ES8500

Ver. 01

9

①Start / Stop: Start & stop the machine. If you press during setting, it returns to the prior condition

*Press the button while Feed Table is moving up & down, the Feed Table stops at current position.

②Set: Sets and stores the selected function.

③Printer Inline: Activate / deactivate Inline function.

*To use Inline operation, you need inline kit (optional) & compatible printer.

④Batch Counter: Enables you to set the number of forms that you wish to process.

⑤Speed (◀▶): Selects yes/no or increase/decrease numerical value when you set.

⑥Reset Counter: Clears the count on the display.

⑦Thickness: Protects the double or multiple feeding.

⑧Jam Free: Reverse rollers for manually remove of paper jam at folding roller or press roller.

*Also aggregates conveyor output

⑨Auto Start: Re-starts the process after selected time when the job reaches preset count.

⑩Manual Feed: Use for single-sheet operation manually.

Operation

OP Panel

OP Panel Functions

2

User Manual ES8500

Ver. 01

Paper Loading

10

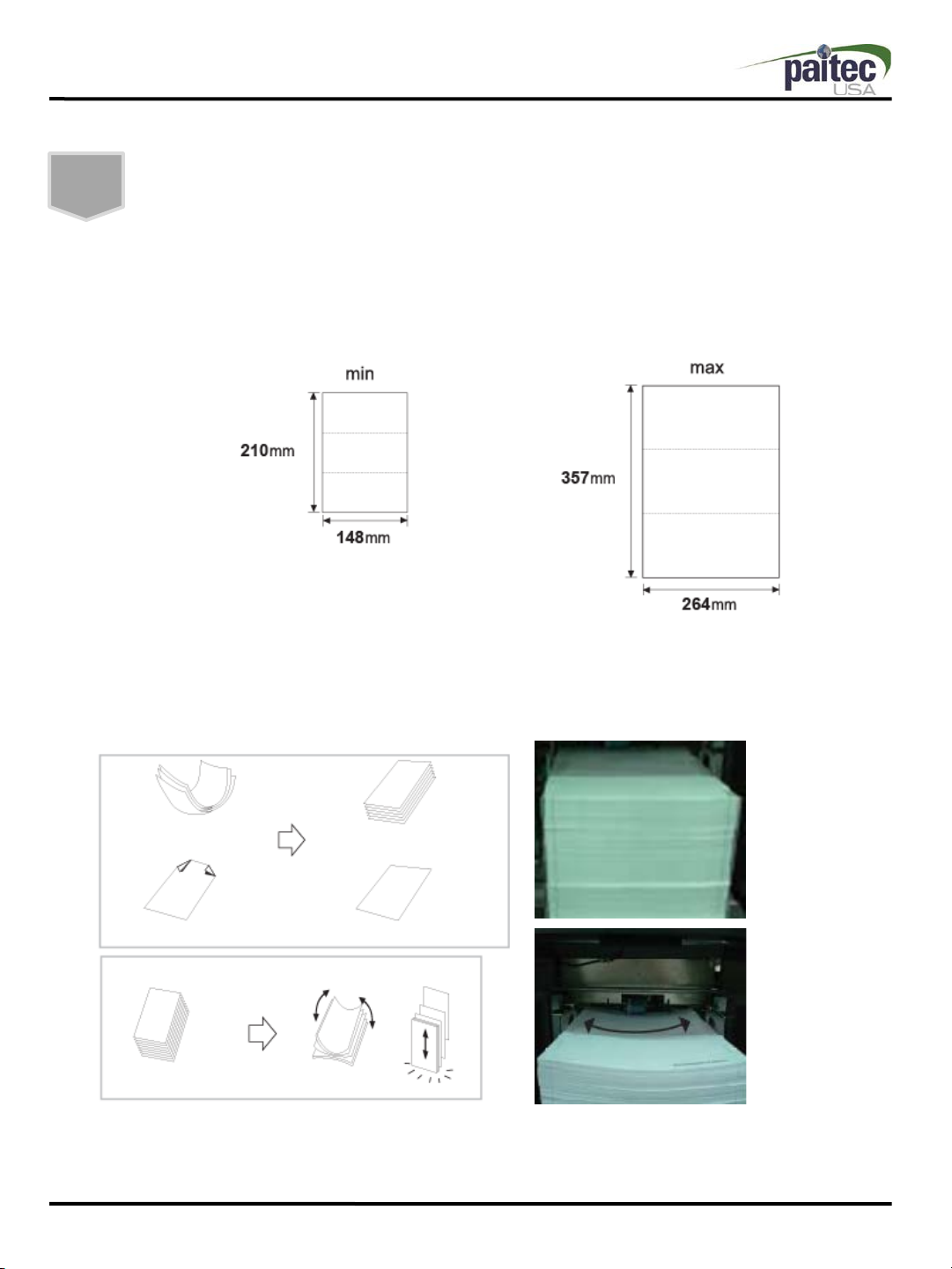

Paper Size

ES8500 handles any form that is larger or smaller than the following forms.

Paper Feeding

1. Before loading the forms onto the machine, please make sure all forms are

aligned and fanned. Please refer to the images below.

If the condition of forms are not good as the picture above (Bad), place

appropriate quantity of forms, unless forms will be jammed.

Good

Bad

Operation

User Manual ES8500

Ver. 01

11

2. Open the safety cover of the feeding unit. The tray will go down.

3. When the feed tray is down to the bottom, loosen the green knobs on both

paper guides.

4. Load the aligned forms onto the feed tray and adjust the paper guides so they

are gently covering the sides of the stacked forms.

5. Tighten back the green knobs on both paper guides.

6. Once loading is complete, please close the safety cover. The feed tray will go up.

Paper Loading

Operation

Make sure the paper guides are not set narrower or wider than the

width of the paper.

Poor quality forms may cause frequent paper jams.

User Manual ES8500

Ver. 01

12

Setting of Paper and Folding Type

The following instruction shows how to set 8 ½” x 11” size Z-Fold.

(Note: Please be noted that the position marker doesn’t guarantee 100% positioning)

1. Lower Cassette Fold Setting - 93mm

1) Unlock the fold position of the lower cassette by turning the stopper locking

knob counter clockwise.

2) Adjust the stopper so the surface of the rubber is lined up at 93mm.

3) Lock the stopper by holding the stopper adjustment knob and turning the

stopper locking knob clockwise.

2. Upper Cassette Fold Setting - 93mm

1) Unlock the fold position of the upper cassette by turning the stopper locking

knob counter clockwise.

2) Adjust the stopper so the red marker is lined up at 93mm..

3) Lock the stopper by holding the stopper adjustment knob and turning the

stopper locking knob clockwise.

Fold Type Setting

Operation

User Manual ES8500

Ver. 01

13

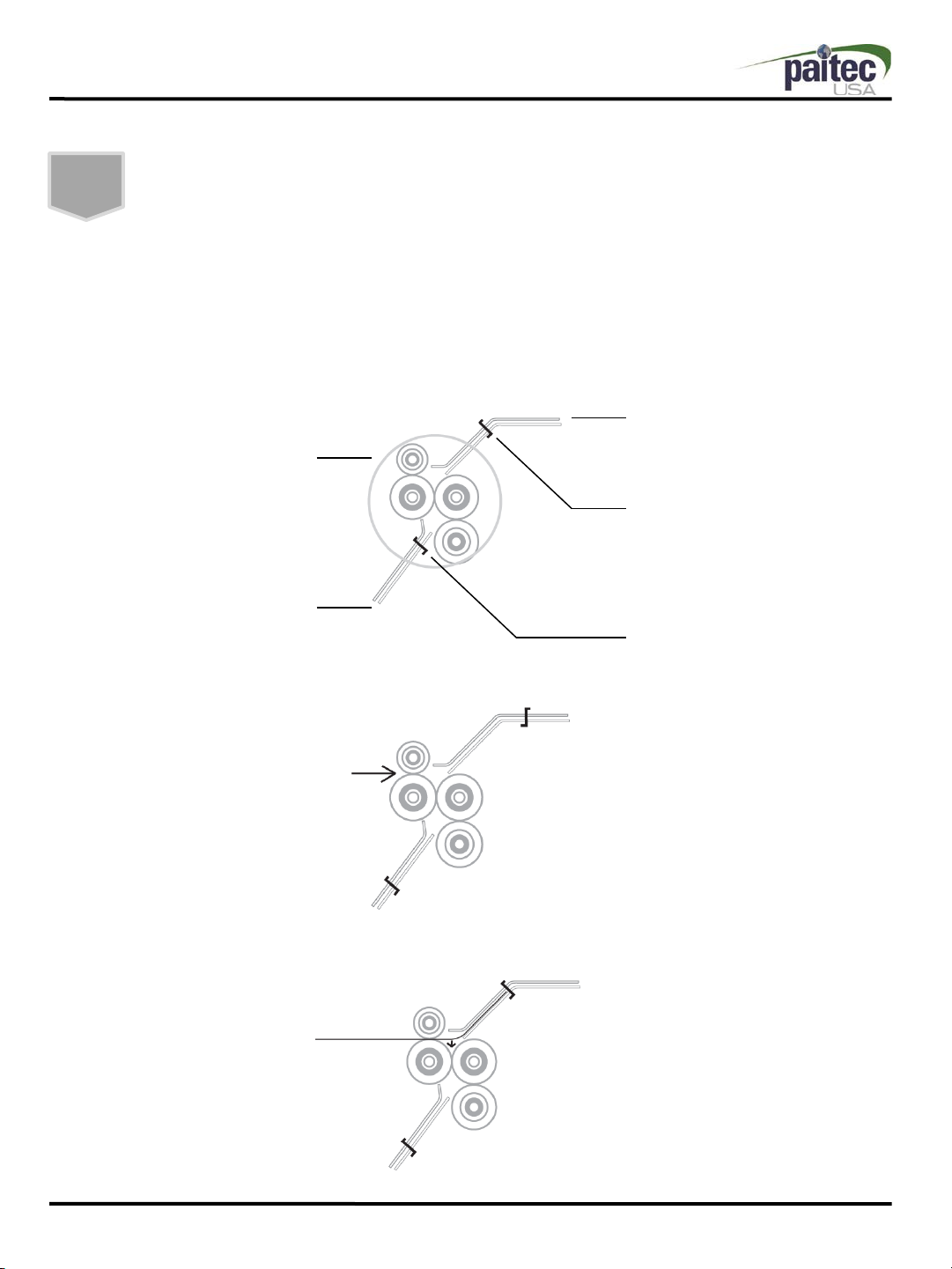

It is important to understand how ES8500 folds paper in order to accurately set

the fold setting. Please read the following information carefully to fully

understand the folding mechanism of ES8500.

1. The folding unit is composed of rollers, cassettes and stoppers.

2. The form enters in between the two front fold rollers.

3. The form hits the upper cassette stopper and buckles in the middle. Then the

folded portion enters in between the middle two rollers.

Upper Cassette Stopper

Upper Cassette

Lower Cassette Stopper

Fold Rollers

Lower Cassette

Understanding Folding Mechanism

Operation

User Manual ES8500

Ver. 01

14

4. The form hits the lower cassette stopper and forms a buckle. The folded form then

enters in between the two outer rollers.

5. The folded form then exits the fold rollers and then are sent to the press unit.

Operation

Understanding Folding Mechanism

User Manual ES8500

Ver. 01

15

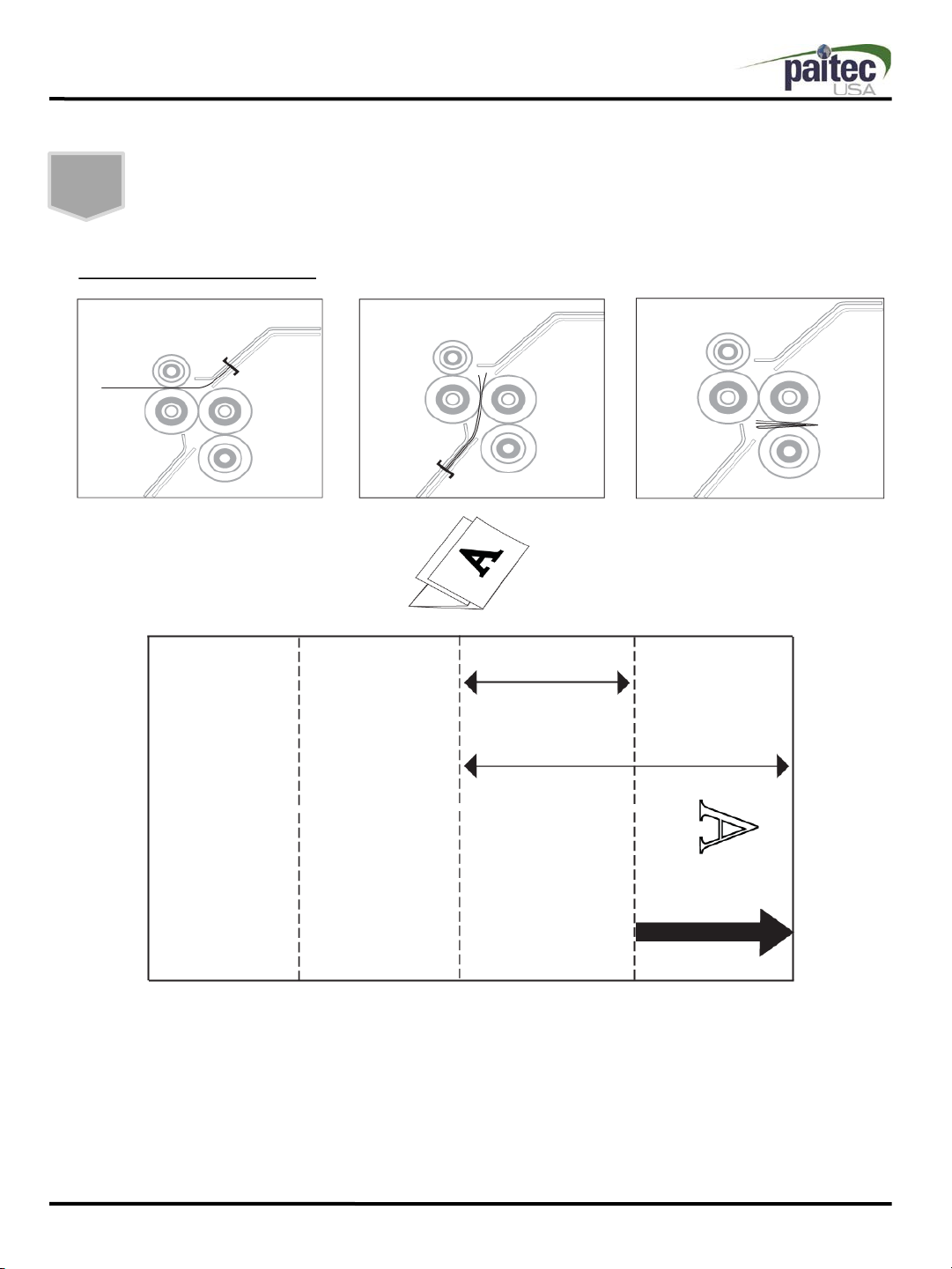

Z-Fold Setting

StopperLower Cassette

In-feed

Direction

Paper

Upper Cassette

①②③

Second Fold

(Lower Cassette)

First Fold

(Upper Cassette)

In-feed Direction

When setting a Z-Fold, please read the following steps.

1. Measure the length from line 1 to line 2 of the form as indicated in the image above.

That measurement is the fold setting for the first (upper fold cassette) fold.

2. Measure the length from line 2 to line 3 of the form as indicated in the image above.

That measurement is the fold setting for the second (lower fold cassette) fold.

Operation

Understanding Folding Mechanism

User Manual ES8500

Ver. 01

16

V-Fold Setting

V-fold Guide

①②

First Fold

(Upper Cassette)

In-feed Direction

When setting a V-Fold, please read the following steps.

1. Measure the length from line 1 to line 2 of the form as indicated in the image above.

That measurement is the fold setting for the first (upper cassette) fold.

2. Make sure the V-fold guide is placed at the entrance of the lower cassette.

Operation

Understanding Folding Mechanism

User Manual ES8500

Ver. 01

17

C-Fold Setting

①

In-feed Direction

When setting a C-Fold, please read the following steps.

1. Measure the length from line 1 to line 3 of the form as indicated in the image above.

That measurement is the fold setting for the first (upper cassette) fold.

2. Measure the length from line 3 to line 2 of the form as indicated in the image above.

That measurement is the fold setting for the second (lower cassette) fold.

②③

Second Fold

(Lower Cassette)

First Fold

(Upper Cassette)

Operation

Understanding Folding Mechanism

User Manual ES8500

Ver. 01

18

Double-Fold Setting

①

In-feed Direction

When setting a Double-Fold, please read the following steps.

1. Measure the length from line 1 to line 3 of the form as indicated in the image above.

That measurement is the fold setting for the first (upper cassette) fold.

2. Measure the length from line 3 to line 2 of the form as indicated in the image above.

That measurement is the fold setting for the second (lower cassette) fold.

②③

Second Fold

(Lower Cassette)

First Fold

(Upper Cassette)

Operation

Understanding Folding Mechanism

User Manual ES8500

Ver. 01

19

Window-Fold Setting

①

In-feed Direction

When setting a Window-Fold, please read the following steps.

1. Measure the length from line 1 to line 4 of the form as indicated in the image above.

That measurement is the fold setting for the first (upper cassette) fold.

2. Measure the length from line 4 to line 2 of the form as indicated in the image above.

That measurement is the fold setting for the second (lower cassette) fold.

②③

Second Fold

(Lower Cassette)

First Fold

(Upper Cassette)

④

Operation

Understanding Folding Mechanism

Table of contents

Other Paitec Food Saver manuals

Paitec

Paitec MX11500 User manual

Paitec

Paitec ES5500 User manual

Paitec

Paitec MX11000 User manual

Paitec

Paitec MX17000 User manual

Paitec

Paitec IM8100 User manual

Paitec

Paitec ES3000 User manual

Paitec

Paitec MX-9000 User manual

Paitec

Paitec MX-13000 User manual

Paitec

Paitec MX-6000 User manual

Paitec

Paitec ES2500 User manual