10 51-4771

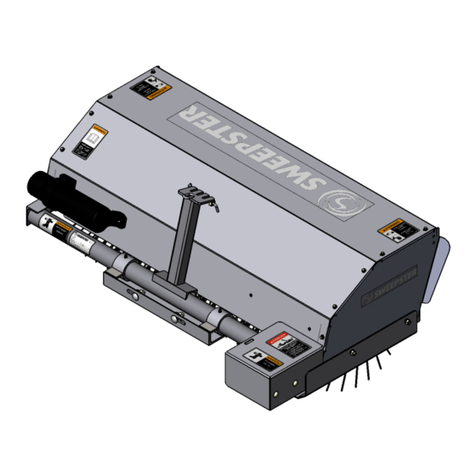

OPERATING THE ATTACHMENT

• Do not exceed the lifting capacity of your prime mover.

• Operate only from the operator’s station.

• When operating on slopes, drive up and down, not across. Avoid steep hillside

operation, which could cause the prime mover to overturn.

• Reduce speed when driving over rough terrain, on a slope, or turning, to avoid

overturning the vehicle.

• An operator must not use drugs or alcohol, which can change his or her alertness

or coordination. An operator taking prescription or over-the-counter drugs should

seek medical advice on whether or not he or she can safely operate equipment.

• Before exiting the prime mover, lower the attachment to the ground, apply the

brakes, turn off the engine and remove the key.

• Remove any large objects from the work area that could harm operator or others

if thrown by sweeper.

• When traveling on rough terrain, reduce speed to avoid “bouncing” the sweeper.

Loss of steering can result.

EQUIPMENT SAFETY PRECAUTIONS

WARNING! KNOW WHERE UTILITIES ARE

Observe overhead electrical and other utility lines. Be sure equipment will clear

them. When digging, call your local utilities for location of buried utility lines, gas,

water,andsewer,aswellasanyotherhazardyoumayencounter.

WARNING! EXPOSURE TO RESPIRABLE CRYSTALLINE SILICA DUST

ALONG WITH OTHER HAZARDOUS DUSTS MAY CAUSE SE-

RIOUS OR FATAL RESPIRATORY DISEASE.

It is recommended to use dust suppression, dust collection and if necessary personal

protective equipment during the operation of any attachment that may cause high

levels of dust.

WARNING! REMOVE PAINT BEFORE WELDING OR HEATING

Hazardousfumes/dustcanbegeneratedwhenpaintisheatedbywelding,soldering

or using a torch. Do all work outside or in a well ventilated area and dispose of paint

and solvent properly. Remove paint before welding or heating.

When sanding or grinding paint, avoid breathing the dust. Wear an approved respi-

rator. If you use solvent or paint stripper, remove stripper with soap and water before

welding.Removesolventorpaintstrippercontainersandotherammablematerial

from area. Allow fumes to disperse at least 15 minutes before welding or heating.

WARNING! END OF LIFE DISPOSAL

Atthecompletionoftheusefullifeoftheunit,drainalluidsanddismantlebysepa-

ratingthedifferentmaterials(rubber,steel,plastic,etc.).Followallfederal,stateand

localregulationsforrecyclinganddisposaloftheuidandcomponents.