Palax Power 100S Translation 1-2017

2

CONTENTS

1Basic specifications and responsibilities .........................................................................4

1.1Foreword ...............................................................................................................................4

1.2EU Declaration of Conformity ............................................................................................5

1.3Intended use of the machine..............................................................................................6

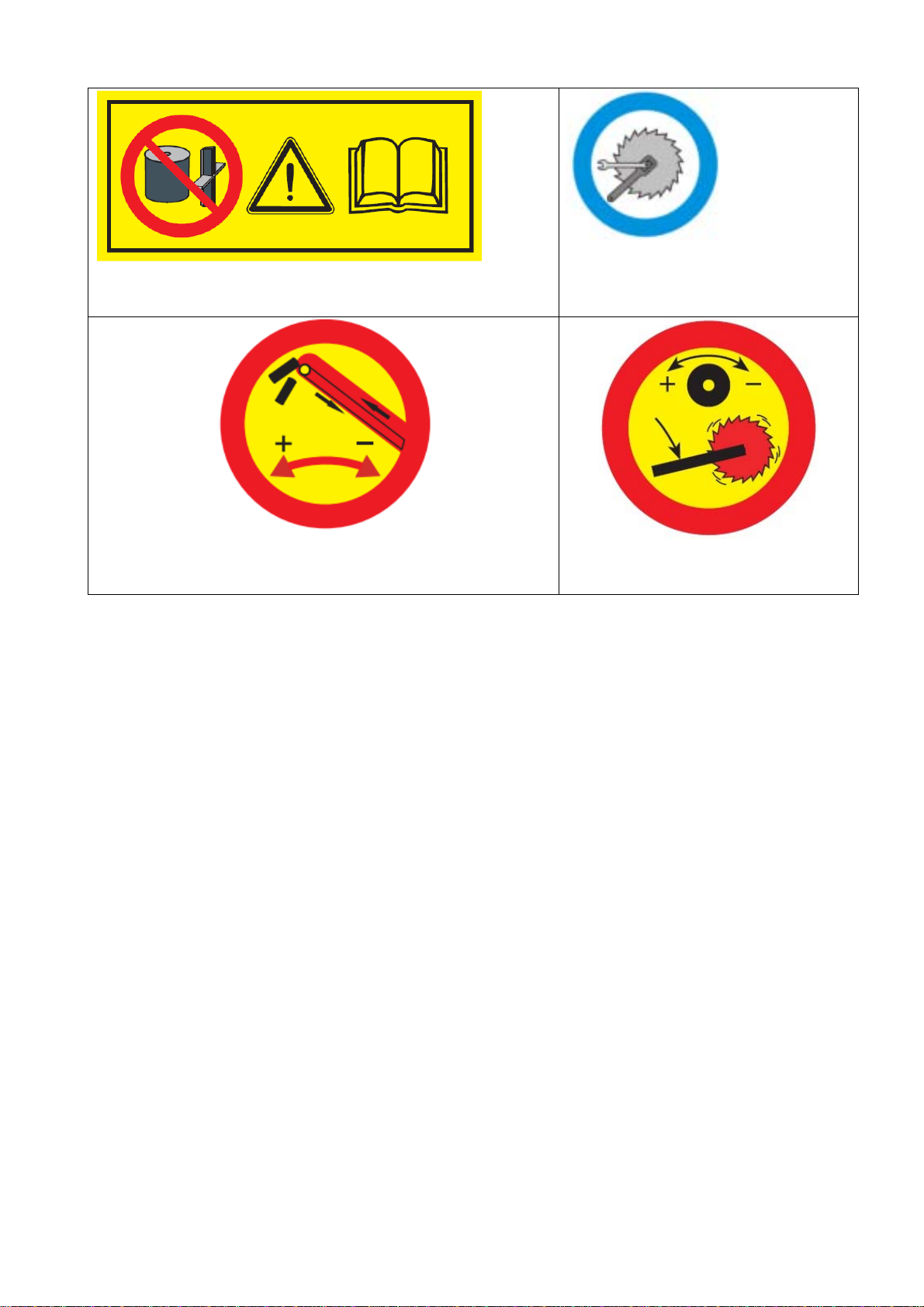

1.4Warning signs.......................................................................................................................6

1.5Nameplates...........................................................................................................................8

1.6The main dimensions and models of the machine.........................................................9

1.7Safety instructions................................................................................................................9

1.8Noise emission and vibration...........................................................................................10

1.9Responsibilities of the operator .......................................................................................10

1.10Operating conditions......................................................................................................10

1.11Terms of warranty...........................................................................................................11

1.12Operating instructions for the winch............................................................................11

2Taking delivery and setting up the machine for operation..........................................12

2.1Lifting the machine.............................................................................................................12

2.2The transport set-up and unpacking...............................................................................12

2.3Acceptance inspection......................................................................................................12

2.4Main parts of the machine................................................................................................13

3Setting up the machine for operation and transportation............................................15

3.1Table extension..................................................................................................................15

3.2Setting the log-stop............................................................................................................15

3.3Bringing the conveyor in work position...........................................................................16

3.4Bringing the conveyor in work position...........................................................................18

4Powered by a tractor.........................................................................................................19

4.1Installation...........................................................................................................................19

4.2Emergency stop switch for a tractor-powered machine...............................................21

4.3Required measures in an emergency situation.............................................................22

4.4Transporting the machine by trailer (Fig. 19) ................................................................22

5Operating the firewood processor..................................................................................23

5.1Electric drive, start and emergency stop........................................................................23

5.2Control of the machine......................................................................................................23

5.3Use of the firewood processor, crosscut operation......................................................23

5.4Operating the crosscut saw, before the operation........................................................24

5.5During the operation..........................................................................................................24

5.6Placing the wood on the deck..........................................................................................24

5.7Crosscut operation.............................................................................................................24

5.8Cutting the last log.............................................................................................................25

5.9Feeding the last log for splitting.......................................................................................25

5.10Disturbances during crosscut operation and their remedy ......................................26