1.0 Warnings and Important Information

WARNING

•Avoid moving machinery, thermal, electrical, and/or chemical hazards as contact may cause serious injury or death.

•Avoid swing falls.

•Follow the weight restrictions and recommendations in this manual.

•Remove from service any equipment subjected to fall arrest forces.

•Remove from service any equipment that fails inspection.

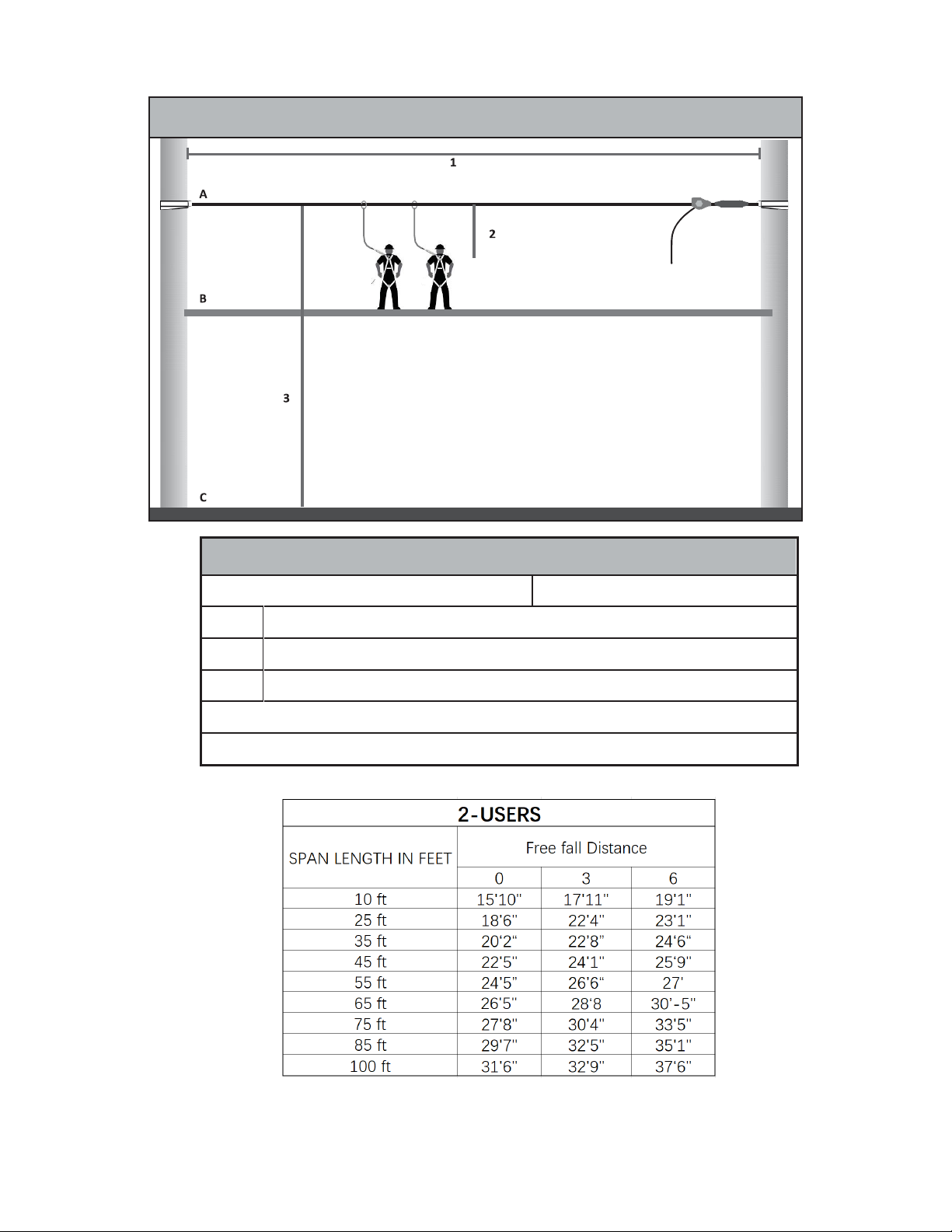

•The lifeline shall be installed higher than the shoulder to limit free fall to 6’ or less*. When using SRDs the lifeline must be positioned overhead. The

deceleration of the self retractable lifeline may be much longer as it declaimed when attach to a flexible anchorage attachment, please Only make sure

to use a self retractable lifeline that has anti-racheting design and will still function on this temporary horizontal lifeline.

•Do not alter or intentionally misuse this equipment.

•Consult PALMER SAFETY when using this equipment in combination with components or subsystems other than those described in this

manual.

•Do not connect rebar hooks, large carabiners, or large snap hooks to the FBH dorsal D-rings as this may cause a roll-out condition and/or

unintentional disengagement.

•Avoid sharp and/or abrasive surfaces and edges.

•Use caution when performing arc welding. Arc flash from arc welding operations, including accidental arcs from electrical equipment, can

damage equipment and are potentially fatal.

•Examine the work area. Be aware of the surroundings and workplace hazards that may impact safety, security, and the functioning of fall arrest

systems and components.

•Hazards may include, but are not limited to, cable or debris tripping hazards, equipment failures, personnel mistakes, or moving equipment

such as carts, barrows, fork lifts, cranes, or dollies. Do not allow materials, tools, or equipment in transit to contact any part of the fall arrest

system.

•Do not work under suspended loads.

•The use of independent HLL systems for each person or shorter span lengths or intermediate anchor points is recommended to minimize the

potential of the other workers falling.

IMPORTANT

This product is part of a personal fall arrest, restraint, work positioning, suspension, or rescue system. A Personal Fall Arrest System (PFAS) is

typically composed of an anchorage and a Full Body Harness (FBH), with a connecting device, i.e., a Shock Absorbing Lanyard (SAL), or a

Compatible Self-Retracting Device (SRD) that has anti-racheting design, attached to the dorsal D-ring of the FBH.

These instructions must be provided to the worker using this equipment. The worker must read and understand the manufacturer’s instructions for

each component or part of the complete system. Manufacturer’s instructions must be followed for proper use, care, and maintenance of this

product. These instructions must be retained and be kept available for the worker’s reference at all times. Alterations or misuse of this product, or

failure to follow instructions, may result in serious injury or death.

A Fall Protection Plan must be on file and available for review by all workers. It is the responsibility of the worker and the purchaser of this

equipment to assure that users of this equipment are properly trained in its use, maintenance, and storage. Training must be repeated at regular

intervals. Training must not subject the trainee to fall hazards.

Consult a doctor if there is reason to doubt your fitness to safely absorb the shock of a fall event. Age and fitness seriously affect a worker’s ability

to withstand falls. Pregnant women or minors must not use this equipment.

ANSI limits the weight of fall protection equipment users to a maximum of 310 lbs. Products in this manual may have a rated capacity exceeding

ANSI capacity limits. Heavy users experience more risk of serious injury or death due to falls because of increased fall arrest forces placed on the

user’s body. In addition, the onset of suspension trauma after a fall event may be accelerated for heavyusers.

The user of the equipment discussed in this manual must read and understand the entire manual before beginning work.

NOTE: For more information consult the ANSI Z359 body of standards.