8

General Work Products LLC | 6000 Jefferson Hwy | Harahan, LA 70123 www.PalmerSafetyUS.com

•Fall Protection •Training •Netting •PPE

1. Refer to Torque Table in following these instructions. Turn

back specied amount of rope from thimble or loop. Apply rst

clip one base width from dead end of rope. Use torque wrench

to evenly tighten clip, alternating from one nut to the other until

reaching the recommended torque.

2. When two clips are required, apply the second clip as near the

loop or thimble as possible. Use torque wrench to evenly tighten

clip, alternating until reaching the recommended torque. When

more than two clips are required, apply the second clip as near

the loop or thimble as possible, turn nuts on second clip rmly,

but do not tighten.

3. When three or more clips are used, space additional clips

equally between rst two. Take up rope slack, use torque wrench

to tighten on each clip evenly, alternating from one nut to the

other until reaching recommended torque.

4. O-rings and sliders: Palmer Safety provides (2) 2-1/2”

O-rings that should be applied to the cable lifeline to allow

compatible attachment of snap hooks and other connecting devices. O-rings and sliders must be attached to the lifeline

before the system is complete.

For systems with multiple intermediate anchor points or for any other questions, contact Palmer Safety Fall Protection.

Maintenance, Cleaning, and Storage

If Cable HLL System fails inspection in any way, immediately remove it from service, and contact Palmer Safety to

inquire about its return or repair.

Cleaning after use is important for maintaining the safety and longevity of Cable HLL System. Remove all dirt,

corrosives, and contaminants from Cable HLL System before and after each use. If Cable HLL System cannot be cleaned

with plain water, use mild soap and water, then rinse and wipe dry. NEVER clean Cable HLL System with corrosive

substances.

When not in use, store equipment where it will not be affected by heat, light, excessive moisture, chemicals, or other

degrading elements.

Inspection

1.) System should be inspected before each use.

If any damage is found or system is involved in a fall remove from jobsite immediately.

2.) System should be inspected by a Competent Person at a minimum of every 6 months.

3.) All inspections should be documented.

Palmer Safety would be glad to help with any inspections.

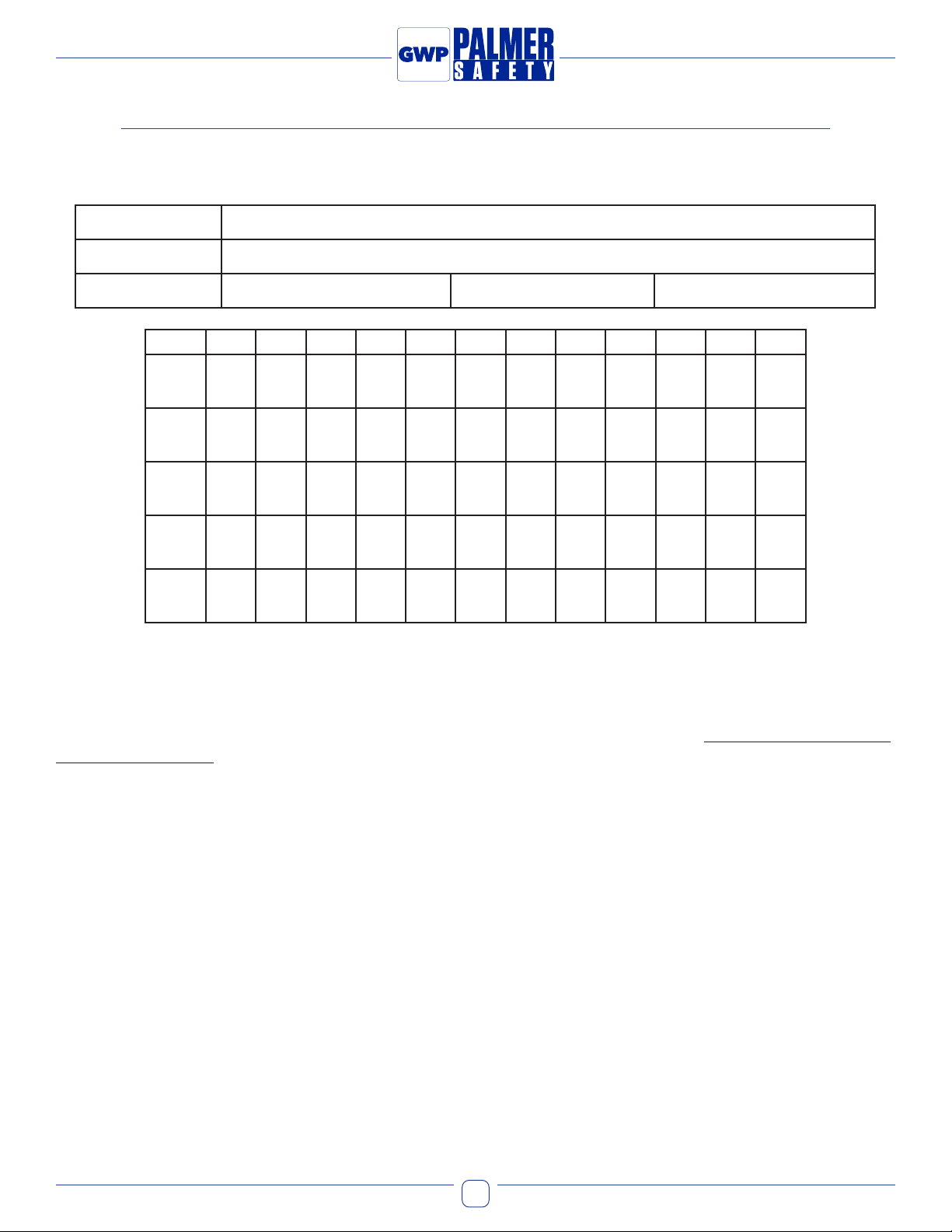

Torque Table

Clip Size

(in.)

Rope Size

(in.)

Minimum #

of Clips

Amount of Rope to

Turn Back (in.)

Torque

(ft. lbs.)

3/16 3/16 2 4 30

1/4 1/4 2 4 30

5/16 5/16 2 5 30

3/8 3/8 2 5¼ 45

7/16 7/16 2 6½ 65

1/2 1/2 3 11 65

9/16 9/16 3 12¾ 130

5/8 5/8 3 13½ 130

3/4 3/4 3 16 225

7/8 7/8 4 26 225

1 1 5 37 225

11/8 11/8 5 41 360

1¼ 1¼ 6 55 360

13/8 13/8 6 62 500

1½ 1½ 7 78 500

1½ 1½ 7 78 500

If greater number of clips than shown are used, amount of turn-back

should be increased proportionately. Torque values shown are based

upon the threads being clean, dry, and free of lubrication.