3

GETTING STARTED SAFETY / SPECIFICATIONS ASSEMBLY / INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /REPAIR

GETTING STARTED

Save this manual

You will need the manual for the safety warnings and precau-

tions, assembly instructions, operating and maintenance

procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover.

Keep this manual and invoice in a safe and dry place for future

reference.

Structural requirements

Make sure all supporting structures and load attaching

devices are strong enough to hold intended loads. If in

doubt, consult a qualified structural engineer.

Electrical requirements

The power supply to the Model 9683315, 10” Band Saw

needs to be 220V AC, 3-phase, 3.2 amps, 60 HZ.

Tools needed

Standard professional mechanic’s hand tool set (socket set,

pliers and spirit level, etc.).

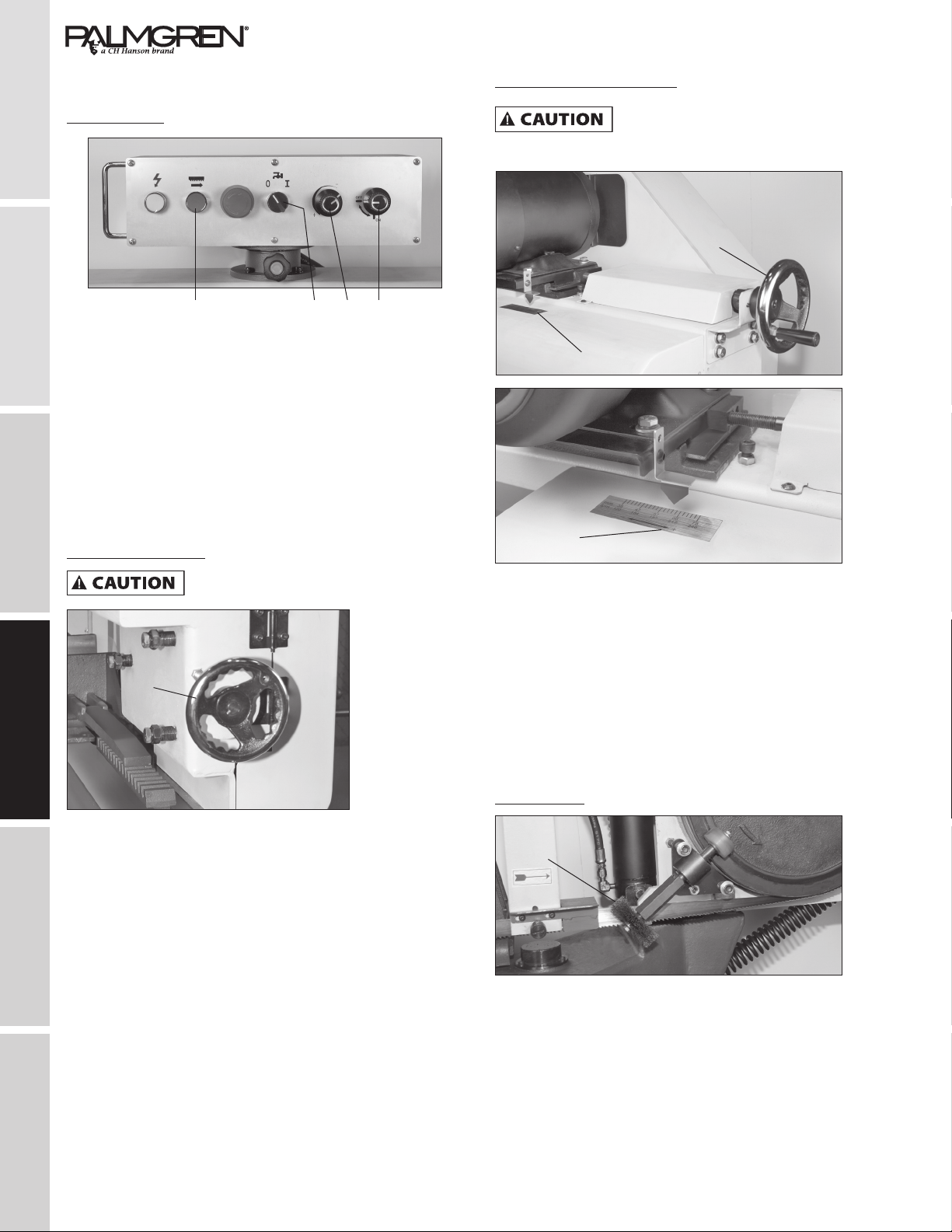

UNPACKING

When unpacking, check to make sure all parts listed below are

included. If any parts are missing or broken, please contact your

local retailer.

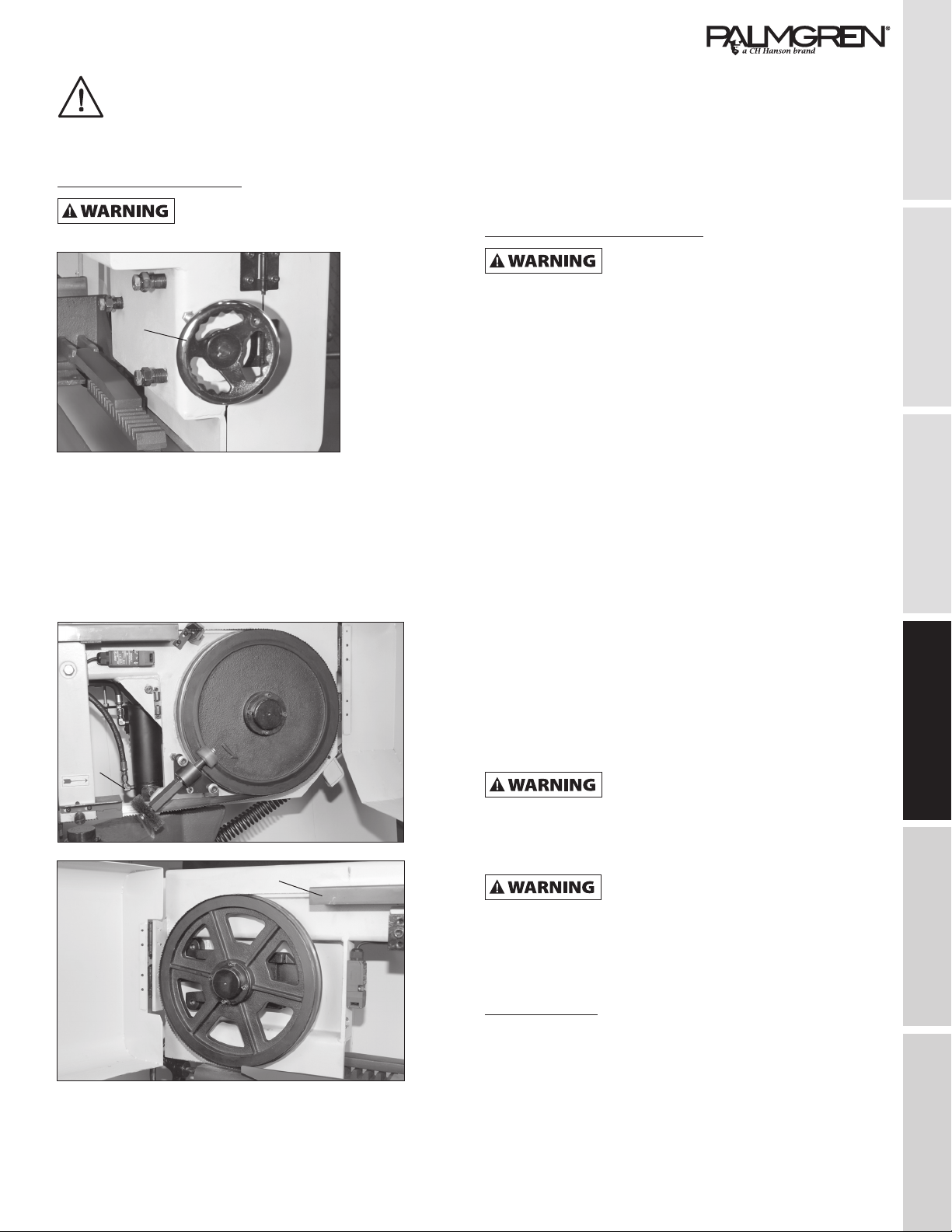

IMPORTANT: Many unpainted steel surfaces have been

coated with a protectant. To ensure proper fit and operation,

remove coating. Coating can be easily removed with mild

solvents, such as mineral spirits, and a soft cloth. Avoid getting

solution on paint or any of the rubber/plastic parts. Solvents may

deteriorate these finishes. Use soap and water on paint, plastic

or rubber components. After cleaning, cover all exposed surfaces

with a light coating of oil.

Never use highly volatile solvents. Non-

flammable solvents are recommended to

avoid possible fire hazard.

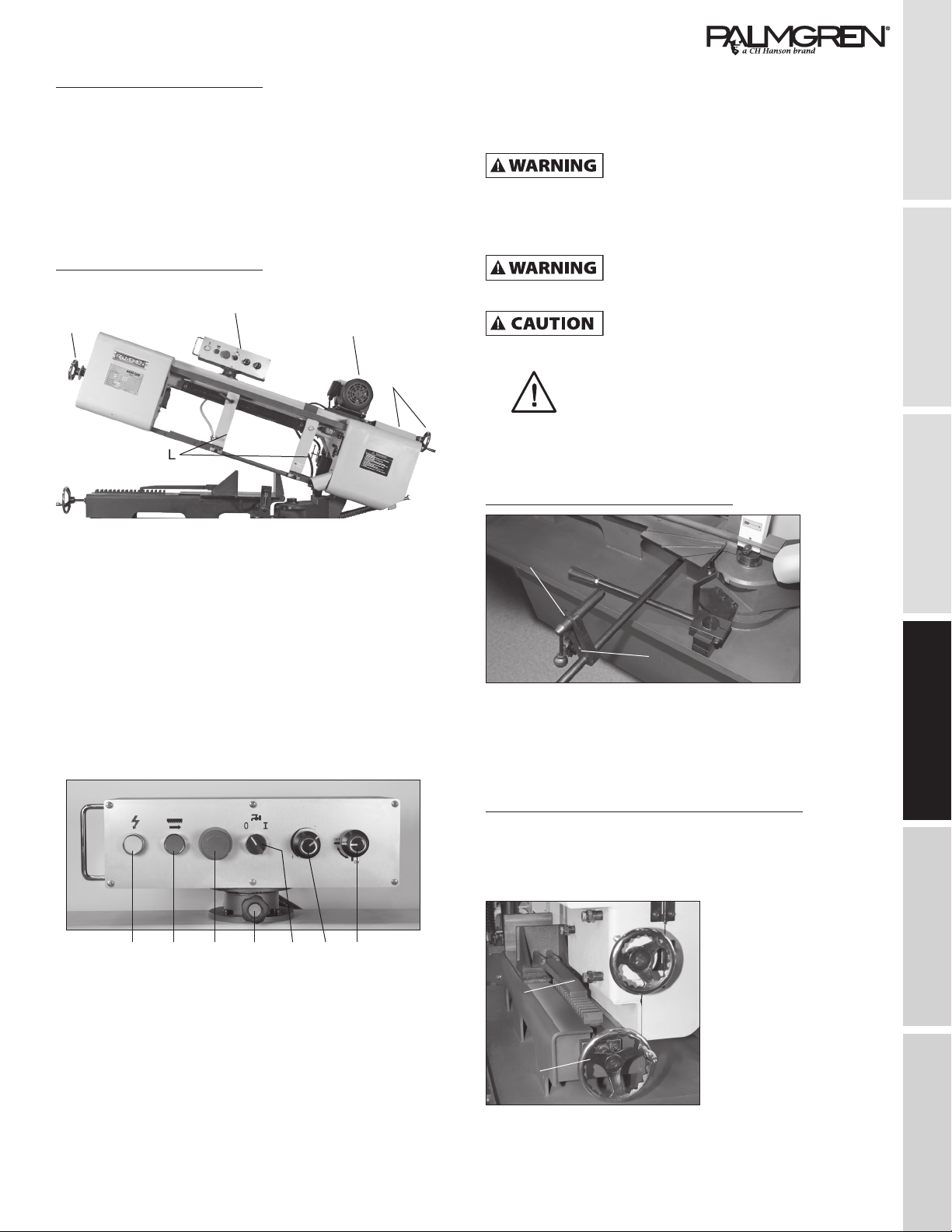

Contents of Model 9683315 10” Band Saw

• Complete Band Saw

• Depth Stop Rod (for assembly see page 6)

• Depth Stop (for assembly see page 6)

• Operating instructions

Unpack

Remove all the over packing materials, but leave unit

attached to its pallet. Do not discard packing materials

until after the machine has been inspected for damage and

completeness. Locate loose parts and set aside.

Inspect

After unpacking the unit, carefully inspect for any

damage that may have occurred during transit. Check

for loose, missing, or damaged parts. Shipping damage

claims must be filed with the carrier.

This machine and its accessories should be visually inspected

before use, in addition to regular periodic maintenance

inspections. Be sure that the voltage labeled on the unit matches

your power supply.

SAFETY RULES

For you own safety, read all of the

instructions and precautions before

operating the tool.

Always disconnect the machine from its

power source before changing blades or

carrying out any maintenance procedure even in the case of

irregular machine operation.

PROPOSITION 65 WARNING: Some dust created by

using power tools contain chemicals known to the state

of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry

products

• Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area and work with approved

safety equipment. Always wear OSHA/NIOSH approved, properly

fitting face mask or respirator when using such tools.

Always follow proper operating

procedures as defined in this manual even

if you are familiar with the use of this or similar tools.

Remember that being careless for even a fraction of a

second can result in severe personal injury.

Read all instructions before using this tool

• Dress properly. Do not wear loose clothing, shirts with

sleeves that are too long, gloves that are too big, jewelry or

chains as they can be caught in moving parts. Protective,

electrically non-conductive clothes and non-skid footwear are

recommended when working. Wear restrictive hair covering

to contain long hair.

• Use eye and ear protection. Always wear ANSI approved

impact safety goggles.

• Stay alert. Watch what you are doing, use common sense.

Do not operate any tool when you are tired.

• Guard against electrical shock. Prevent body contact with

grounded surface such as pipes, radiators, ranges and

refrigerator enclosures.

• Do not operate tool if under the influence of alcohol or drugs.

Read warning labels on prescriptions to determine if your

judgement or reflexes will be impaired. If there is any doubt,

do not operate the tool.

Prepare work area for job

• Keep work area clean and free of equipment, tools or other

objects. Cluttered areas invite injuries.

• Observe work area conditions. Do not use machines or

power tools in damp or wet locations. Do not expose to rain.