15

ERROR INDICATION

In case of errors, attempt the following measures.

Error

indication Description Remedy

EEPROM is broken or reached the end of its

working life.

EEPROM writing error

Load of the sensing output is short-circuited

Turn OFF the power and check the load.

mounted in cascade.

Verify that there is no loose or clearance between

Communication error between the upper com-

Verify that there is no loose or clearance between

16

SPECIFICATIONS

Type Series connection type

NPN output PNP output

Model No. FX-501 FX-501P

Supply voltage 12 to 24V DC % Ripple P-P10% or less

Power consumption

(Note 1)

Normal operation: 960mW or less (current consumption 40mA or less at 24V supply voltage)

Eco mode: 680mW or less (current consumption 28mA or less at 24V supply voltage)

Sensing output

NPN open-collector transistor

Maximum sink current: 100mA (Note 1)

Applied voltage: 30V DC or less

(Between sensing output and 0V)

Residual voltage: 2V or less (Note 2)

[At 100m

A (Note 1)

sink current]

PNP open-collector transistor

Maximum source current: 100mA (Note 1)

Applied voltage: 30V DC or less

(Between sensing output and +V

)

Residual voltage: 2V or less (Note 2)

[At 100m

A (Note 1)

source

current]

Output operation Switchable either Light-ON or Dark-ON

Short-circuit protection

Incorporated

Response time

U-LG: 4ms or less, HYPR: 24ms or less, Selectable

Protection IP40 (IEC)

Ambient temperature

-10 to +55°C (If 4 to 7 units are mounted in cascade: -10 to +50°C or if 8 to 16 units are

mounted in cascade: -10 to +45°C) (No dew condensation or icing allowed)

Storage: -20 to +70°C

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Material Enclosure: Polycarbonate, Key: Polyacetal, Protective cover: Polycarbonate

Weight (Main body only)

Approx. 15g

Accessory FX-MB1

Notes:1) 50mA max. if 5 or more series connection types are connected together.

2) In case of using the quick-connection cable (cable length 5m) (optional).

3) Cables are not accessories. Be sure to use cables in table below.

Cable

Cable length 1m Cable length 2m Cable length 5m

Main cable Sub cable Main cable Sub cable Main cable Sub cable

CN-73-C1 CN-71-C1 CN-73-C2 CN-71-C2 CN-73-C5 CN-71-C5

17

CAUTIONS

This product has been developed / produced for industrial use only.

Take care that if a voltage exceeding the rated range is applied, or if an AC

power supply is directly connected, the product may get burnt or be damaged.

Take care that short-circuit of the load or wrong wiring may burn or damage

the product.

Do not run the wires together with high-voltage lines or power lines, or put

them in the same raceway.This can cause malfunction due to induction.

Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that the

frame ground (F.G.) terminal of the power supply is connected to an actual

ground.

In case noise generating equipment (switching regulator, inverter motor, etc.)

is used in the vicinity of this product, connect the frame ground (F.G.) terminal

of the equipment to an actual ground.

The ultra long distance (U-LG, HYPR) mode is more likely to be affected by

extraneous noise since the sensitivity of that is higher than the other modes.

Make sure to check the environment before use.

Do not use during the initial transient time (H-SP, FAST, STD: 0.5 sec., LONG,

U-LG, HYPR: 1 sec.) after the power supply is switched ON.

Be sure to using the quick connection cable (optional) as cable. When you ex-

tend the cable, be sure to use cables which have 0.3mm2or more of conductor

cross-section area. Extension up to total 100m is possible. However, in order

to reduce noise, make the wiring as short as possible.

Make sure that stress by forcible bend or pulling is not applied to the sensor

This product is suitable for indoor use only.

Avoid dust, dirt, and steam.

Take care that the product does not come in contact with oil, grease, organic

solvents such as thinner, etc., strong acid or alkaline.

-

plosive gasses.

Never disassemble or modify the product.

This product adopts EEPROM. Settings cannot be done 100 thousand times

or more because of the EEPROM’s lifetime.

13

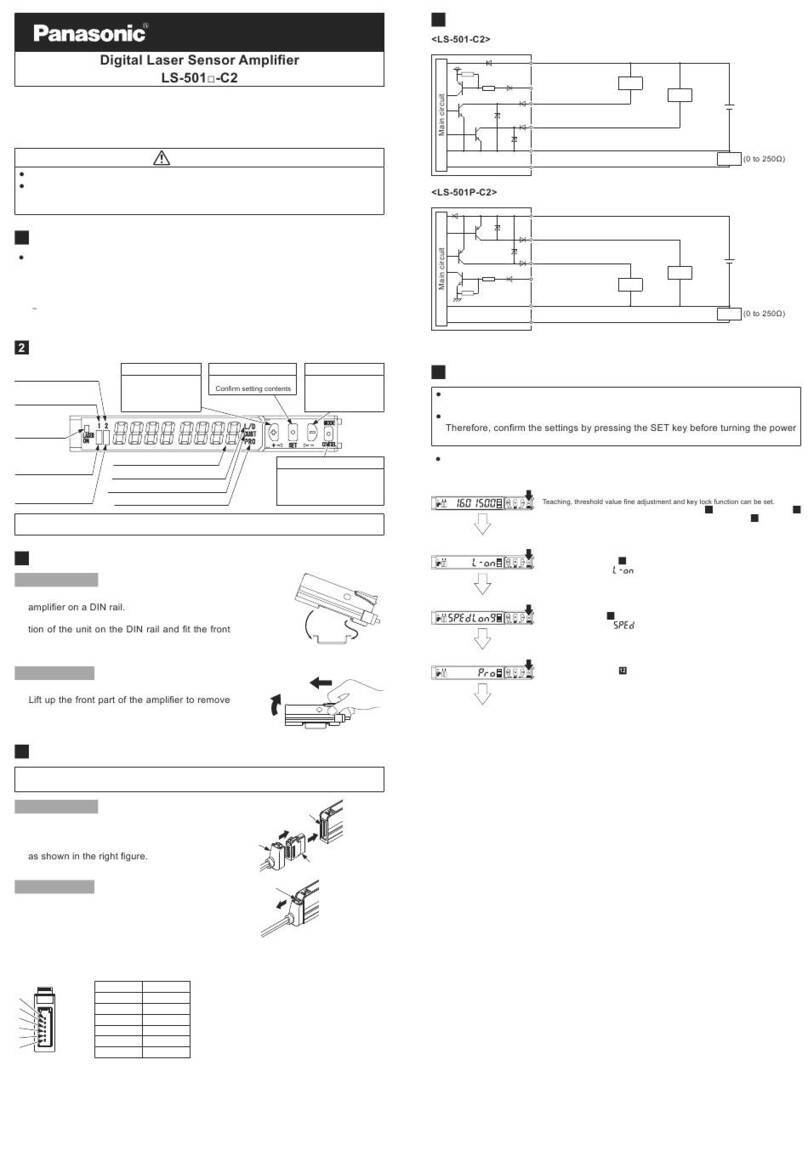

OPTICAL COMMUNICATION

When the setting of data bank loading / saving, copy setting, or copy action

However, in case using data bank loading / saving, use FX-502FX-505-C2

loading / saving, or copy setting cannot be carried out.

Copy lock setting is set to copy lock ON “ .”

Digital display is blinking

“ .” (Only data-

bank loading / saving)

When communication protocol of a

sub amplifier is set to communication

emission halt “ ” the setting

of data bank loading / saving, or copy

setting cannot be carried out to sub

Make sure to mount closely like follows

since interference prevention function is

conducted by optical communication.

Main

Communication direction

sensor controllers, etc.) are connected together in cascade, install those prod-

-

ure. This product is included in Group D.

Group

A

Group

B

Group

D

Group

C

Communication direction

Group Model No.

AFX-301

FX-301BGHLS-401

BFX-301

FX-305FX-301-C1

CLS-403DPS series

DFX-500 series

-

FX-MB1 (optional) on the communication window of each

corresponding product.

Within each group, identical models should be connected in a lump.

In case conducting copy setting of this device and other FX-500 series togeth-

er, functions which are incorporated in this device will be copied but functions

which are not incorporated in this device will not be copied.

14

INTERFERENCE PREVENTION FUNCTION

This device incorporates an interference prevention function by setting different emit-

ting frequencies from an interference prevention function by optical communication.

For Interference prevention function setting procedure, refer to <PRO5> in

“PRO MODE OPERATION MANUAL.”

as shown in table below.

Response time

Interference

prevention function setting

H-SP FAST STD LONG U-LG HYPR

0248812

-

Example: Putting in 12 of this device and set STD of response time setting.

Possible number of interference prevention is 4.

8th to OFF since interference prevention works from 1st to 4th, from 5th to

8th and 9th to 12th.

Communication direction

Interference

prevention

possible

range

Put a protection seal between

Or set communication protocol

setting in 4th to OFF.

Put a protection seal between

Or set communication protocol

setting in 8th to OFF.

Interference prevention

possible range

Interference prevention

possible range

For communication protocol setting procedure, refer to <PRO4> in “PRO

MODE OPERATION MANUAL.”

http://panasonic.net/id/pidsx/global

© Panasonic Industrial Devices SUNX Co., Ltd. 2012

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

About our sale network, please visit our website.

PRINTED IN CHINA

5DPFR1DWLRQDO *RW4XHVWLRQV" QVDOHV#UDPFRLFRP ZZZ3DQDVRQLF6HQVRUVFRP