Panasonic DMR-EH50GN User manual

Other Panasonic DVR manuals

Panasonic

Panasonic BB-HNP11CE User manual

Panasonic

Panasonic WJ-HD616/1000 User manual

Panasonic

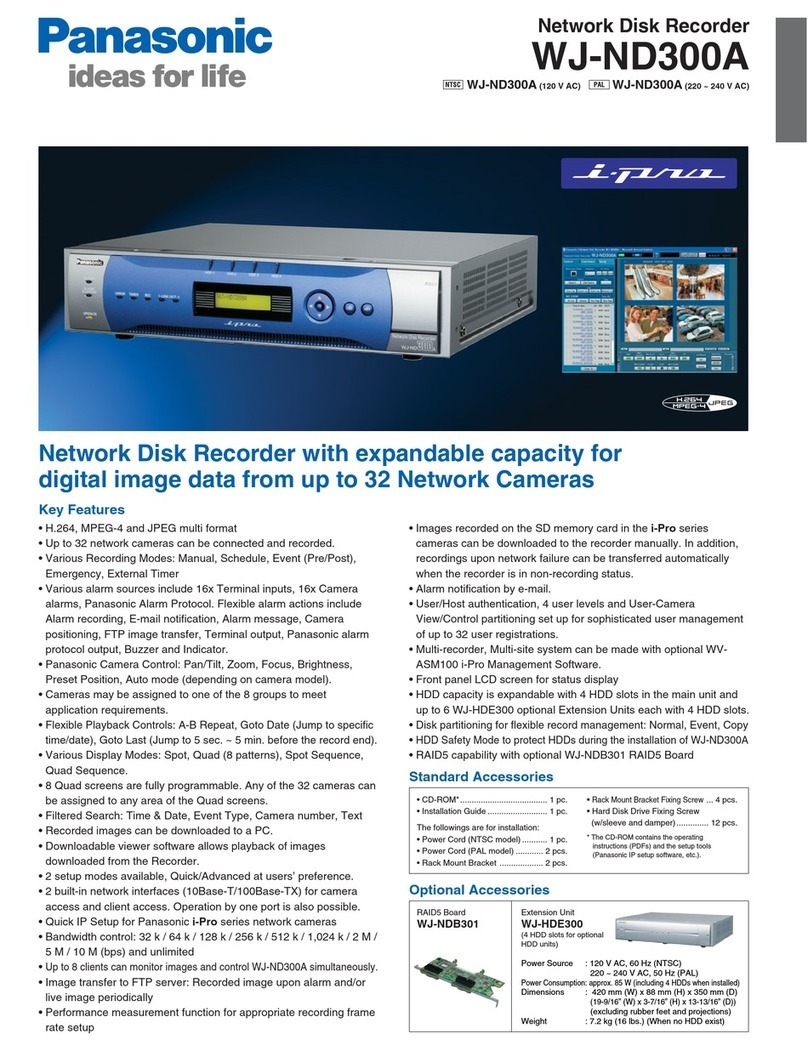

Panasonic WJ-ND300A/10000V User manual

Panasonic

Panasonic Showstopper PV-HS2000 User manual

Panasonic

Panasonic DMR-E500HS User manual

Panasonic

Panasonic WJ-HD716 User manual

Panasonic

Panasonic AJ-SPD850MC User manual

Panasonic

Panasonic WJHD316 - DIGITAL DISK RECORDER Quick guide

Panasonic

Panasonic Diga DMR-E65 User manual

Panasonic

Panasonic WJ-HD300A Reference manual

Panasonic

Panasonic DMR-E30 User manual

Panasonic

Panasonic DMRHS2 - DVD RECORD.W/HD DRIV User manual

Panasonic

Panasonic DMR-EH60PC User manual

Panasonic

Panasonic AG-CPDIOCRUP User manual

Panasonic

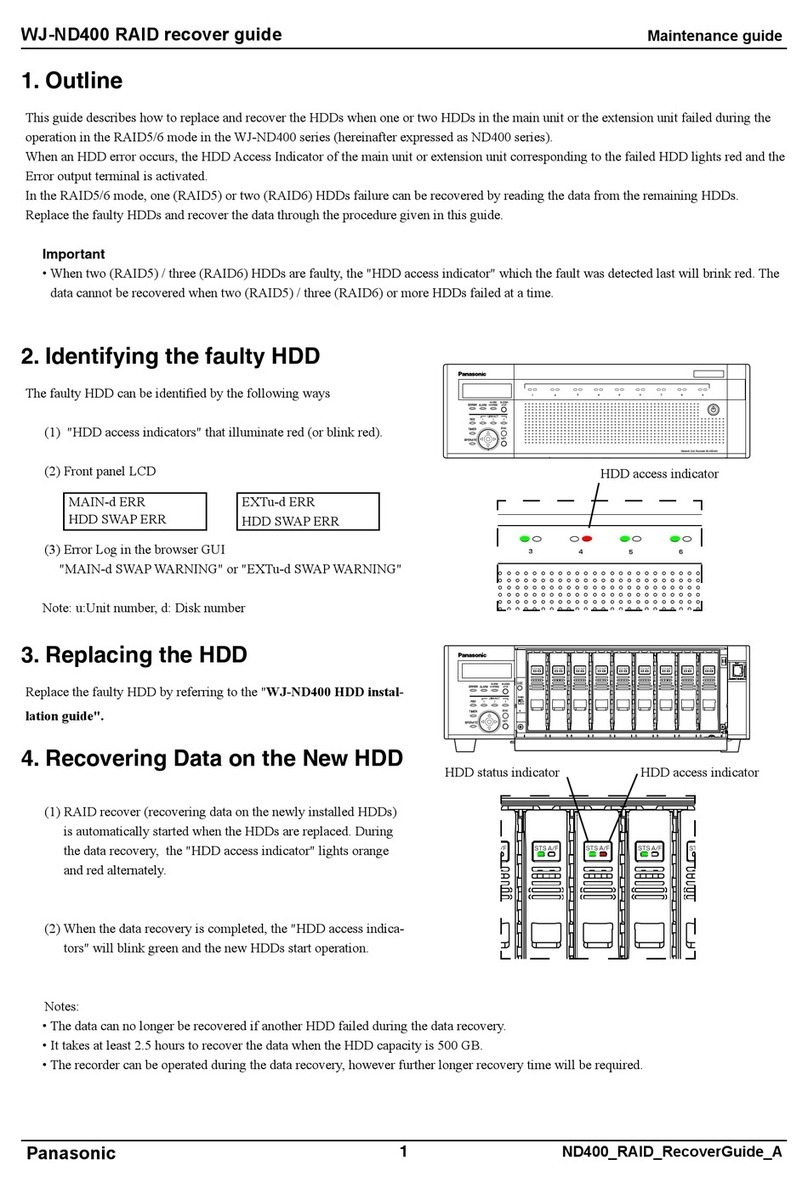

Panasonic WJND400 - NETWORK DISK RECORDER Operating manual

Panasonic

Panasonic WJ-NV200K User manual

Panasonic

Panasonic K-NL316K User manual

Panasonic

Panasonic Showstopper PV-HS2000 User manual

Panasonic

Panasonic DMR-E85HP User manual

Panasonic

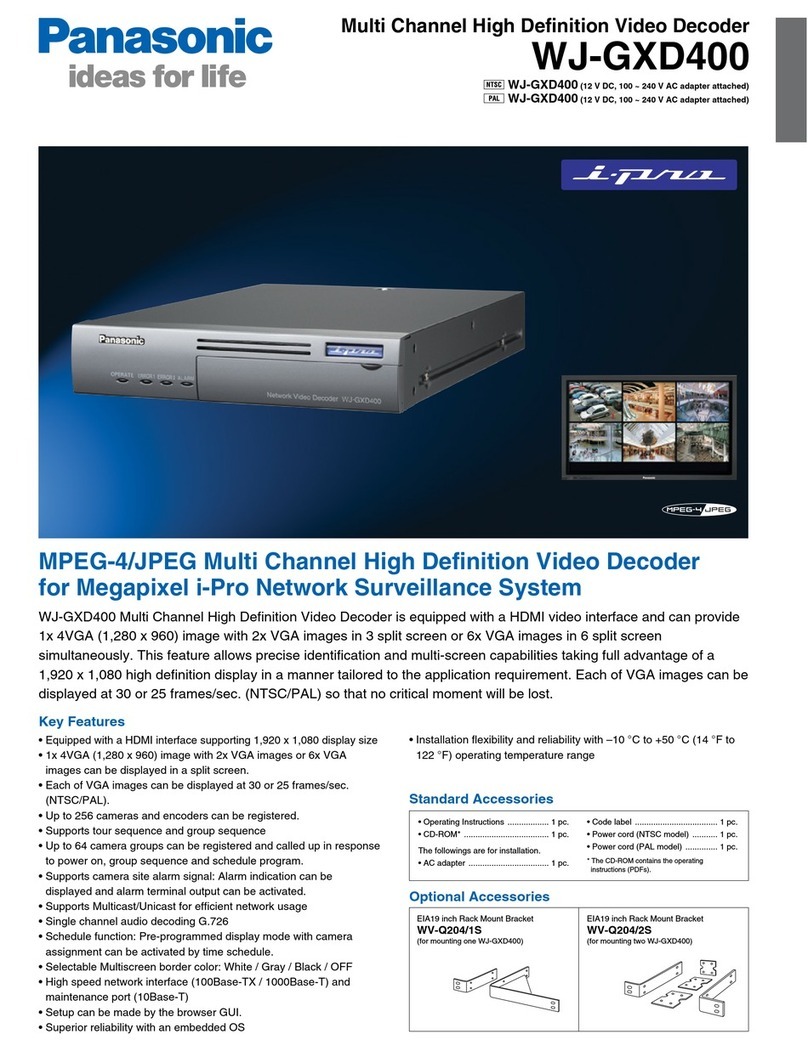

Panasonic WJ-GXD400 User manual