PACD011001G2 / PACD011004G3

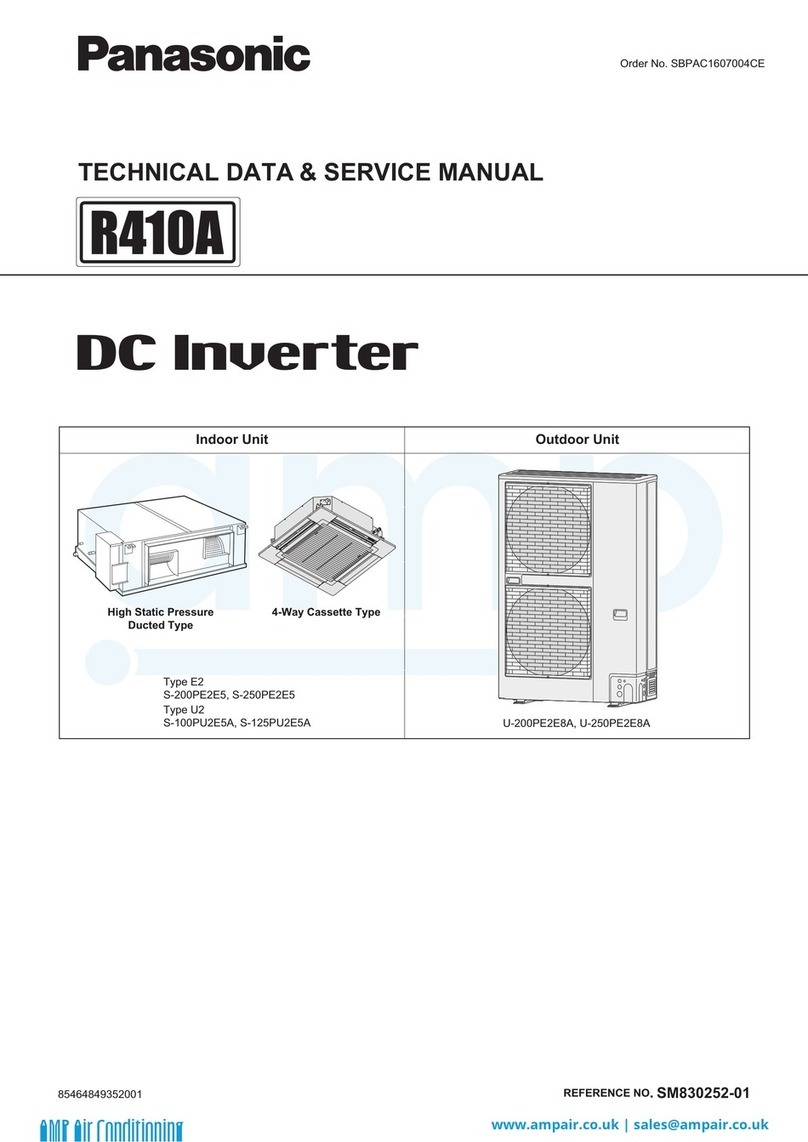

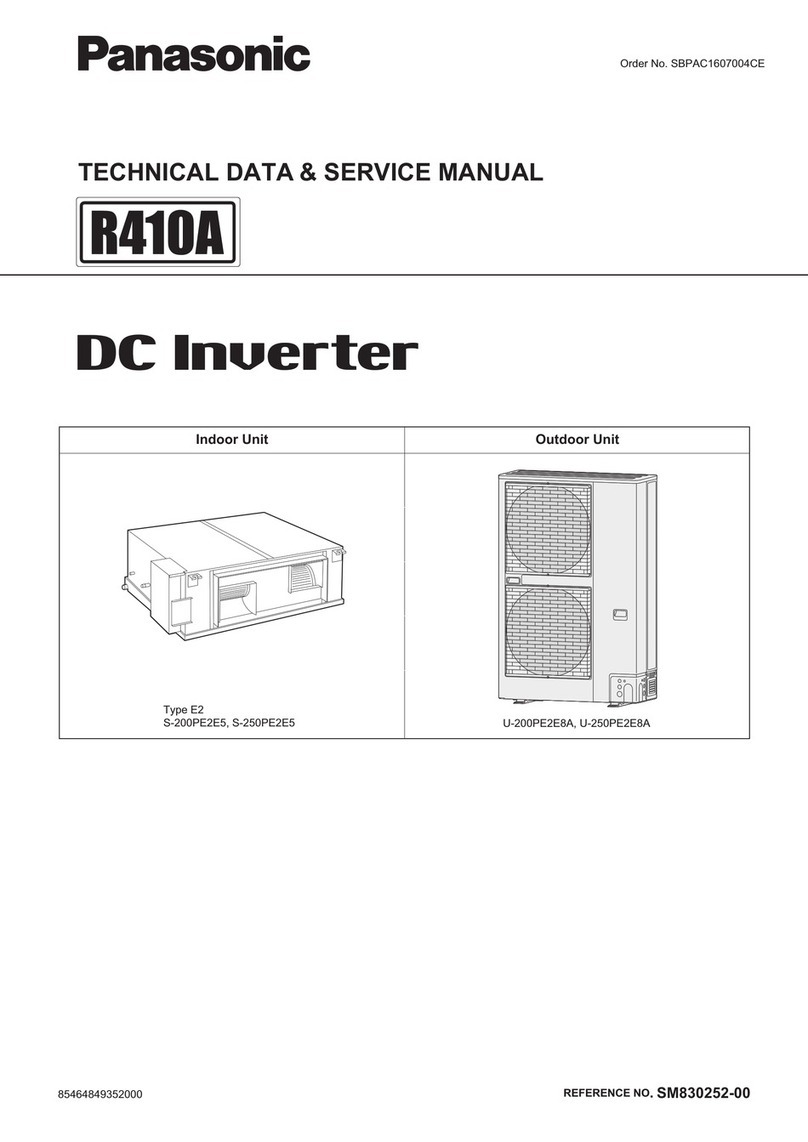

Urban Multi Inverter “MX1” Series 1

Urban Multi

Inverter “MX1” Series

1. General ...................................................................................................3

1.1 What is “Urban Multi Series”? ..................................................................3

1.2 The Installation is of Vital Importance ......................................................5

2. Points to Bear in Mind at the System Design..........................................6

2.1 Points Relating to the Performance of the Air Conditioning Units............6

2.2 Striking a Balance between System Installation and

General Construction Work (Comprehensive Flow Chart).......................7

2.3 Points to Bear in Mind when Preparing the Contract Drawings ...............8

3. Installation 1..........................................................................................11

3.1 Step by Step Installation Procedure.......................................................11

3.2 Work Involved in Individual Operations

and Points to be Borne in Mind..............................................................12

4. Installation 2..........................................................................................57

4.1 Field Settings..........................................................................................57

4.2 Setting Modes ........................................................................................59

5. Caution for Refrigerant Leaks...............................................................67

5.1 Caution for Refrigerant Leaks ................................................................67

6. Hand Over to Customer........................................................................70

6.1 Operational Steps...................................................................................70

7. Bad Examples and Good Examples in Installation ...............................71

7.1 Example 1: Signal interference due to use of multiple core cable

(all model)...............................................................................................71

7.2 Example 2: Mismatch between cables connecting indoor and

outdoor units and corresponding piping. (all model) ..............................72

7.3 Example 3: Drain pipe trap shape defective...........................................73

7.4 Example 4: Pressure down despite absence of leaks

during air tight test (all model)................................................................74

7.5 Example 5: Excessive noise due to

incorrect angling of Line branch pipes....................................................75

7.6 Example 6: Cracks develop in field pipes due to

thermal expansion and contraction ........................................................76

7.7 Example 7: Transmission wiring between the cool/heat selector and

the outdoor unit is too close to a high voltage wire. ...............................77

7.8 Example 8: The centralized control group number cannot be set

(MX1 Series). .........................................................................................78

7.9 Example 9: “88” cannot be cleared

from the central remote controller. .........................................................79

8. Appendix (Check Points in Installing UM Series)..................................80

8.1 Operating Noise of Indoor Units.............................................................80

8.2 Procedures for Rigging Refrigerant Piping.............................................83

8.3 Piping System Diagrams and Refrigerant Piping Work

for the Inverter MX1 Series ....................................................................87

8.4 Locating Outdoor Units...........................................................................92

8.5 Precaution in Control Wiring Work.........................................................94