Read this manual and related documents before attempting to install, operate,

service or inspect the inverter.

Make sure that you have an understanding of the device, the safety information

and all precautions before starting use. Precautions described in this manual are

divided into two grades: "Caution" and "Note".

: indicates dangerous situations that could lead to personal

injury or death by mishandling the equipment.

: indicates dangerous situations that could lead to moderate

or slight personal injury or property damage by mishandling

the equipment.

In addition, failure to follow the precautions described in

may

lead to serious situations in different conditions.

Please follow the information and instructions as laid out in this manual

carefully to avoid damage to equipment or risk to personal injury.

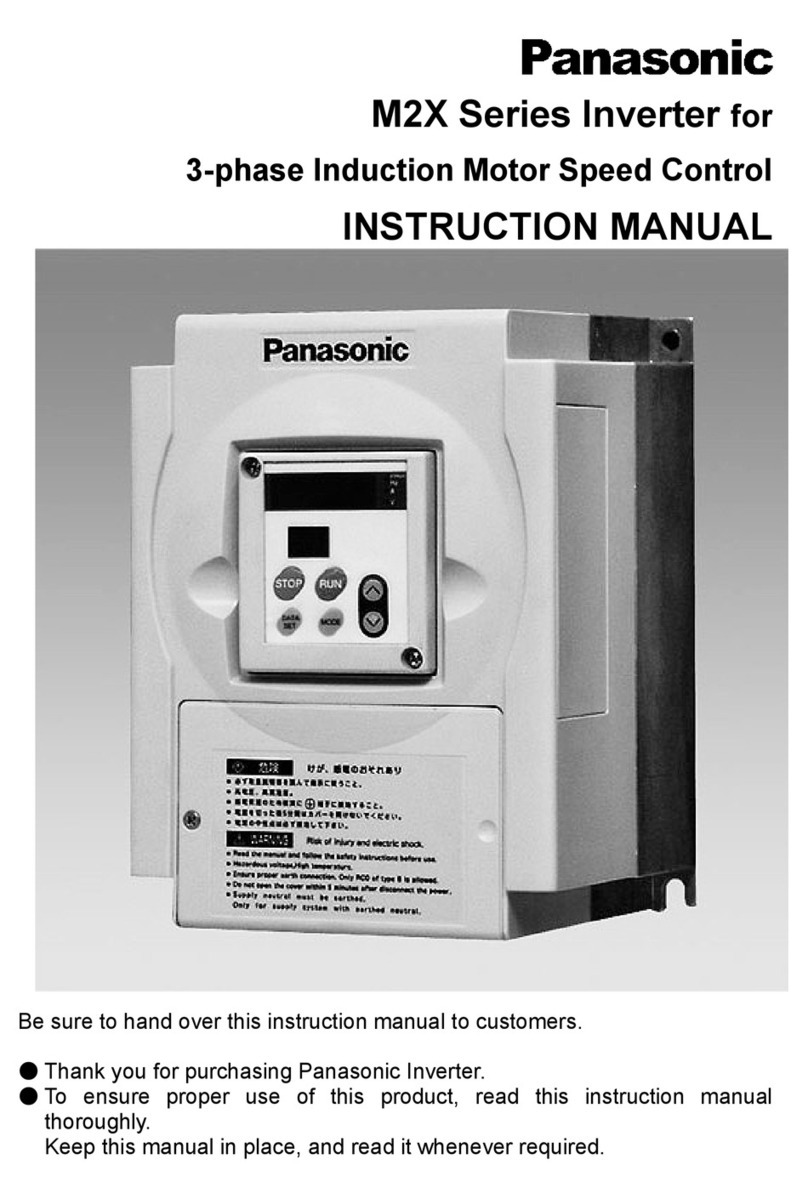

Thank you for purchasing the general-purpose VF100 series inverter produced

by Panasonic Electric Works Automation Controls (Shanghai) Co., Ltd.

Usage methods and precautions are described in this instruction manual.

Read this manual carefully before attempting to operate the inverter and

store it for future reference.

●This general-purpose inverter produced by our company is not designed or

manufactured to be used in equipment or system in situations that can affect

or endanger human life.

When considering this product for operation in special applications such as

machinery or systems used in movable body, medical, aerospace, nuclear energy

control, or submarine relay applications, please contract us.

●Although this product was manufactured under strict quality control conditions,

it is strongly advised to install safety devices to forestall serious accidents when

used in facilities where a breakdown of this product is likely to cause a serious

human injury or generate major losses.

●Do not use this product for loads other than a 3-phase induction motor.

ATTENTION

!

1

!

!Caution

Note

!

Note

Foreword

Safety Precautions