Panasonic KV-S6055W User manual

Other Panasonic Scanner manuals

Panasonic

Panasonic KV-S2048C User manual

Panasonic

Panasonic KV-S2065L User manual

Panasonic

Panasonic KV-S6040W - Document Scanner User manual

Panasonic

Panasonic KV-S7075C User manual

Panasonic

Panasonic KV-SS855 User manual

Panasonic

Panasonic KV-S2025C User manual

Panasonic

Panasonic KX-S300 User manual

Panasonic

Panasonic KV-S4065CL - Sf Clr Duplex 65PPM USB 2.0 Lgl 300PG... User manual

Panasonic

Panasonic KV-SS855D User manual

Panasonic

Panasonic KV-N1028X User manual

Panasonic

Panasonic KV-S1058Y User manual

Panasonic

Panasonic KV-S1057C User manual

Panasonic

Panasonic KV-S4085CW - Document Scanner User manual

Panasonic

Panasonic KV-N1058X User manual

Panasonic

Panasonic KV-S5076H User manual

Panasonic

Panasonic Workio KV-S7065C User manual

Panasonic

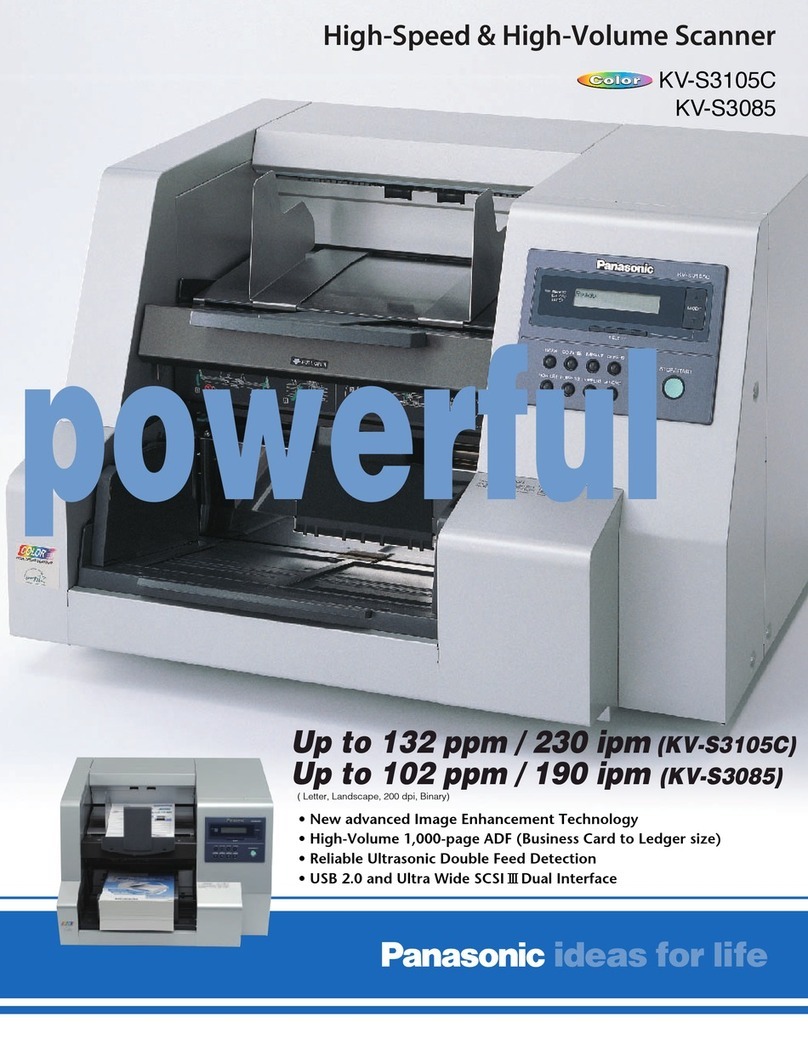

Panasonic KV-S3085 User manual

Panasonic

Panasonic KV-SS50 User manual

Panasonic

Panasonic KV-S1065C User manual

Panasonic

Panasonic Workio KV-S7065C User manual