The state under which the strobe dots seem to be power source affects the strobe illuminator, the strobe

stationary represents the correct number of revolu

-

dot pattern also seems to fluctuate to a certain extent.

tions. But the unit is not affected by

-

the fluctuations of the

"+"

direction

power source, since a D.C. motor is employed.

This increases the speed of the turntable rotation, and

5,

If the desired speed can not be obtained by the variable

the strobe dot pattern seems to flow in the same pitch controls, turn the speed adjusting screws with a

direction as the rotational direction of the turntable screw driver for further adjustments. (See Fig.

9)

platter.

"-"

direction

This decreases the speed of the turntable rotation,

resulting in a state opposite to that in the

"+"

direc

-

tion.

Note:

Strobe dot pattern.

The strobe illuminator/pilot lamp of this unit employs

the commercially available power source. The frequency

of such power source, when actually measured, has a

fluctuation of about 0.2%. As such a fluctuation of the

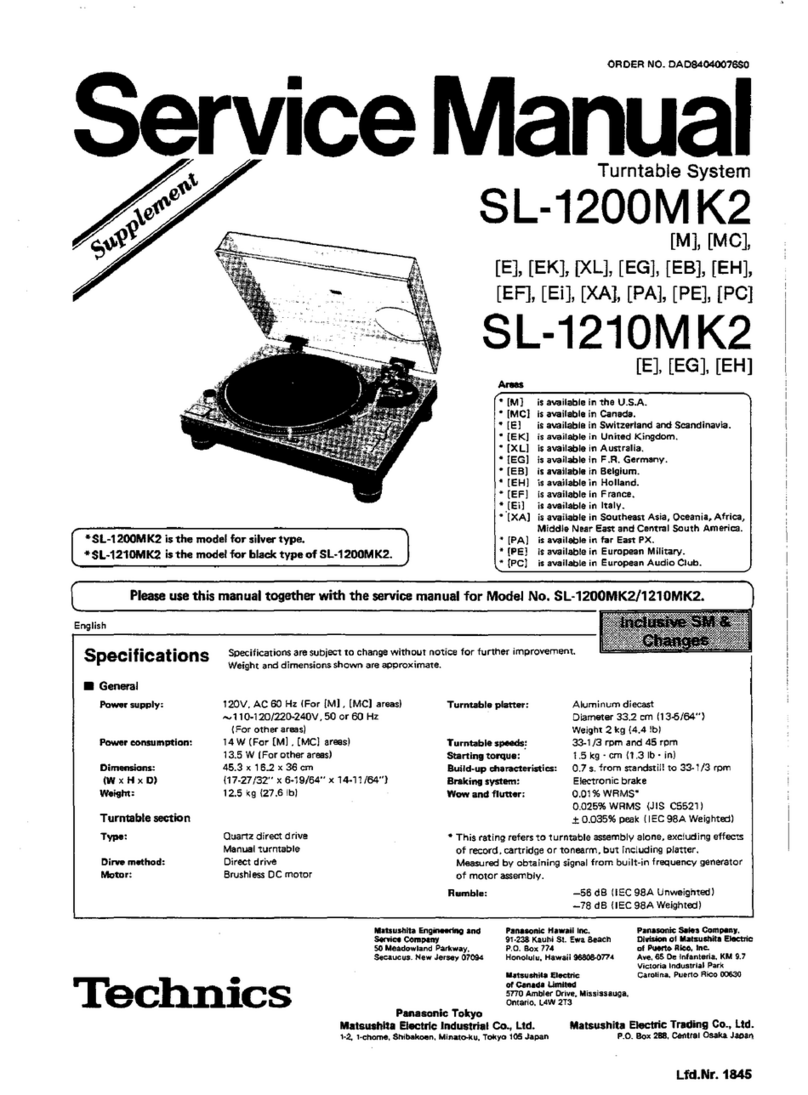

Cross sectionof motor portionand double insulator

Motor shaft (Center spindle) Position detecting rotor

Tonearm

Turntable mat Dust cover

Stator

I

Position detecting coil

I

I-

\

Main base \tator frame

V

isco-elastic material

Operation principles of the

SL

-

1600

Arm base

This unit, like the SL 1300 has a rational motor structure, and its drive control circuit is the B.F.G. type (Back

TECHNICAL EXPLANATION electromotive force frequency generator) which is constructed on a single integrated

circuit (IC) chip (AN630). The following is a block diagram of the IC (AN6303 for which the operating principle will

be briefly explained

Operating principle

The back electromotive force, which is generated by the

drive coil winding according to the rotation of the

motor, is detected and converted to a frequency signal

that is proportional to the numder of revolutions.

Conversion is performed by a wave

-

shaping circuit and a

logic circuit (This is referred to as the B.F.G. method).

This frequency signal is compared with a standard signal

by means of a frequency

-

voltage conversion circuit

which converts

it

to a voltage signal in order maintain a

constant number of revolutions. After removing un

-

necessary

frequency components, with

-

the operational

-

amplifier

active filter, from this voltage signal, itcontrols the cur

-

rent flow in three differential switching circuits. As a

result, the flow of current in the drive coil winding is

always constant maintaining the correct rotational spe

-

ed. Control of the rotational speed can be performed by

means of adjusting the standard signal generator circuit

according to the rotational speed adjustment cricuit.