6

(C) Domestic Hot Water Tank Pipework

•

It’s strongly recommended to install an expansion vessel (field supply) in the

Domestic Hot Water Tank circuit. Refer Typical Piping Installation section to

locate the expansion vessel.

Recommended pre-charge pressure of the expansion vessel (field supply)

= 3.5bar (0.35MPa)

•

In high water pressure or water supply is above 5bar, please install the Pressure

Reducing Valve for water supply. If the pressure higher than that, it might

damage the Tank Unit.

•

A Pressure Reducing Valve (field supply) with below specification is strongly

advised to be installed along the line of the tube connector iof Tank Unit. Refer

Typical Piping Installation section to locate both of these valves.

Recommended Pressure Reducing Valve specifications:

-Set pressure: 3.5bar (0.35MPa)

•

Must connect a faucet to Tank Unit Tube Connector jand main water supply,

in order to supply water with appropriate temperature for shower or tap usage.

Failure to do so might cause scalding.

•

Failure to connect the tube appropriately might causing the Tank Unit malfunction.

(D) Drain Elbow and Hose Installation

•

Fix the Drain Elbow 2and Packing 3to the bottom of Drain Water Hole

h

.

Packing 3

Drain Elbow 2

•

Use inner diameter 17 mm drain hose in the market, fix to Drain Elbow 2.

•

This hose must to be installed in a continuously downward direction and in a

frost-free environment. Improper drain piping may cause water leakage hence

damage the furnitures.

•

If drain hose is long, use a metal support fixture along the way to eliminate the

wavy pattern of drain tube.

•

Guide the drain hose to outdoor as illustrated.

Discharge below

fixed grating

Fixed grating

Trapped gulley

Possible wall

Illustration of guide drain hose to outdoor

•

Do not insert this hose into sewage or drain pipe that may generate ammonia

gas, sulphuric gas etc.

•

If necessary, use hose clamp to further tighten the hose at drain hose connector

to prevent leakage.

•

Water will drip from this hose, therefore the outlet of this hose must be installed

in an area where the outlet cannot become blocked.

•

If drain hose is in the room (where dew may form), please increase the insulation

by using POLY-E FOAM with thickness 6 mm or above.

(E) Domestic Hot Water Tank Discharge (Drain Tap) and Safety Relief

Valve Pipework

•

Safety Relief Valve 8bar (0.8MPa) incorporated in Domestic Hot Water Tank.

•

Drain Tap and Safety Relief Valve discharge fittings share the same drainage outlet.

•

Use R½” male connector for this drainage outlet connection (Tube connector

g

).

•

Piping must always be installed in a continuously downward direction. It must not

be longer than 2m, with no more than 2 elbows, and must not allow condensation

to build up or freezing to occur.

•

The pipe from this drainage outlet fitting must not be shut off. The discharge

must be freed.

•

The end of this pipework must be in such a way so that the outlet is visible and can

not cause any damage. Keep away from electrical components.

•

It is recommended to fit a tundish into this

g

pipework. Tundish should be visible

and positioned away from frost environment and electrical components.

WARNING

This section is for authorized and licensed electrician only. Work

behind the Control Board Cover 5secured by screws must

only be carried out under supervision of qualified contractor,

installation engineer or service person.

CONNECT THE CABLE TO

THE TANK UNIT

4

CAUTION

Please take extra precaution when open

the control board cover 5and control

board 6for unit installation and servicing.

Failure to do so may cause injury.

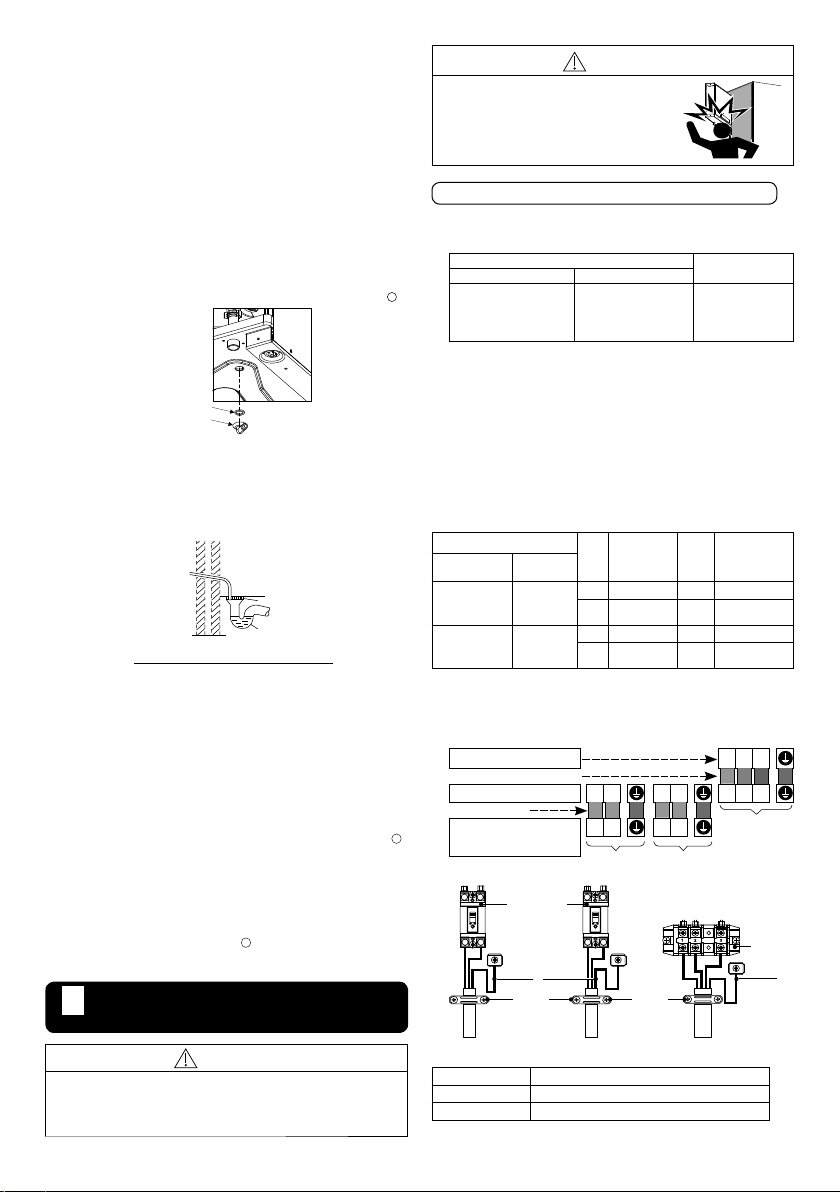

Fixing of Power Supply Cable and Connecting Cable

1.

Connecting cable between Tank Unit and Outdoor Unit shall be approved

polychloroprene sheathed flexible cord, type designation 60245 IEC 57

or heavier cord. See below table for cable size requirement.

Model Connecting Cable

Size

Tank Unit Outdoor Unit

WH-ADC0509L3E5,

WH-ADC0509L3E5AN,

WH-ADC0509L6E5,

WH-ADC0509L6E5AN

WH-WDG05LE5*

WH-WDG07LE5*

WH-WDG09LE5* 4 x min 2.5 mm2

• Ensure the colour of wires of Outdoor Unit and the terminal no.

are the same to the Tank Unit respectively.

• Earth wire shall be longer than the other wires as shown in the

figure for the electrical safety in case of the slipping out of the

cord from the Holder (Clamper).

2. An isolating device must be connected to the power supply cable.

• Isolating device (disconnecting means) should have minimum

3.0 mm contact gap.

• Connect the approved polychloroprene sheathed power

supply 1 cord and power supply 2 cord and type designation

60245 IEC 57 or heavier cord to the terminal board, and to the

other end of the cord to isolating device (Disconnecting means).

See below table for cable size requirement.

Model Power

Supply

Cord

Cable Size Isolating

Devices

Recommended

RCD

Tank Unit Outdoor Unit

WH-ADC0509L3E5,

WH-ADC0509L3E5AN

WH-WDG05LE5*

WH-WDG07LE5*

WH-WDG09LE5*

1 3 x min 2.5 mm225A 30mA, 2P, type A

2 3 x min 1.5 mm215/16A 30mA, 2P, type AC

WH-ADC0509L6E5,

WH-ADC0509L6E5AN

WH-WDG05LE5*

WH-WDG07LE5*

WH-WDG09LE5*

1 3 x min 2.5 mm225A 30mA, 2P, type A

2 3 x min 4.0 mm230A 30mA, 2P, type AC

3. To avoid the cable and cord being damaged by sharp edges, the

cable and cord must be passed through a bushing (located at the

bottom of Control Board 6) before terminal board. The bushing

must be used and must not be removed.

Terminals on the Outdoor Unit

123

Colour of wires (Connecting cables)

Terminals on the Tank unit

LN L1N1123

(Power Supply Cord)

Terminals on the isolating devices

from power supply (Disconnecting

means)

LN L1N1

Power Supply 1 Power Supply 2

Tank Unit/

Outdoor Unit

connection

Power Supply 2 Cable

Power Supply 1 Cable

Terminal

Board

RCCB/ELCB

*1 *1

Connecting Cable

Holder

(Clamper) Holder

(Clamper)

Terminal screw Tightening torque cN•m {kgf•cm}

M4 157~196 {16~20}

M5 196~245 {20~25}

*1 - Earth wire must be longer than other cables for safety reasons