© Panduit Corp. 2016

Page: 1 of 2

CONTROLLED CYCLE FERRULE CRIMPING TOOL

OPERATION, INSPECTION and MAINTENANCE INSTRUCTIONS

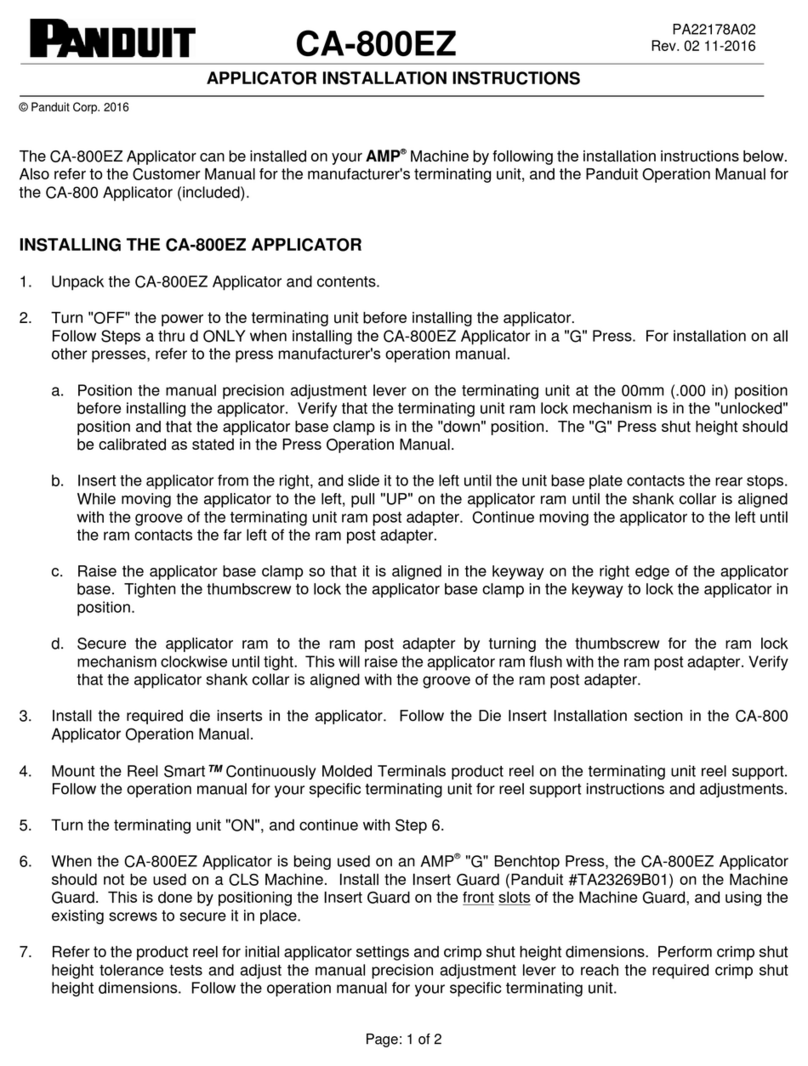

1. With the handles in the open position, insert the ferrule

into the crimp pocket. Make sure that the ferrule is

inserted fully into the crimp die (see Figure 2).

2. Insert the stripped wire into the ferrule until the wire

stops. efer to product packaging for wire strip length.

3. Crimp the ferrule by closing the handles until the

controlled cycle mechanism releases. Upon release,

the handles will open automatically and the crimped

ferrule can be removed.

NOTE: Crimp entire uninsulated ferrule length. This may

require additional crimps.

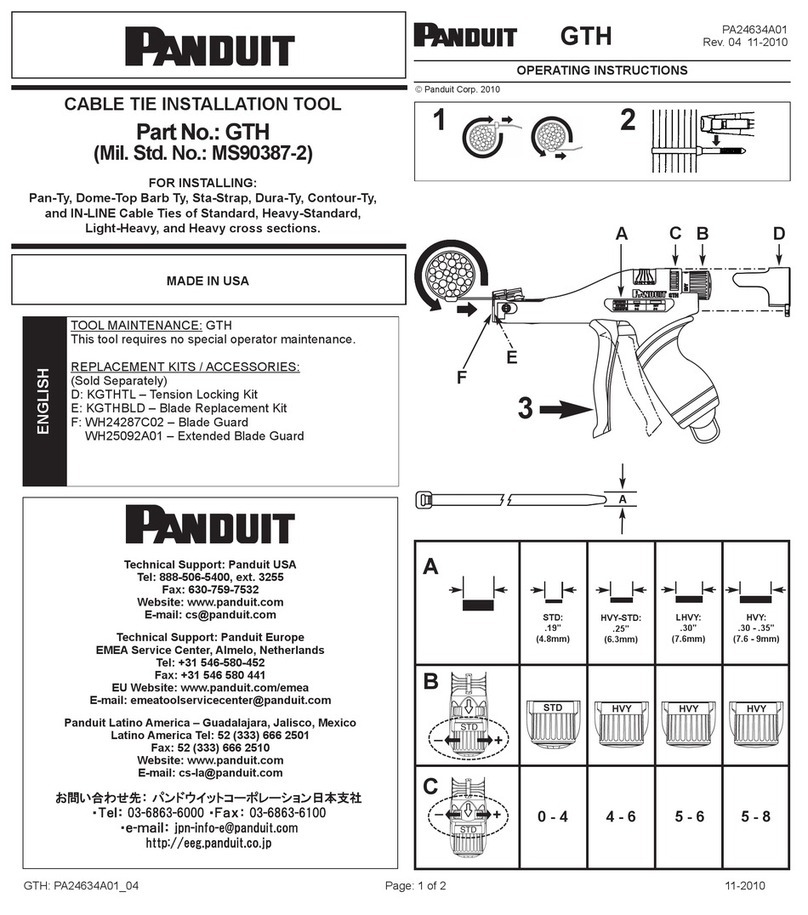

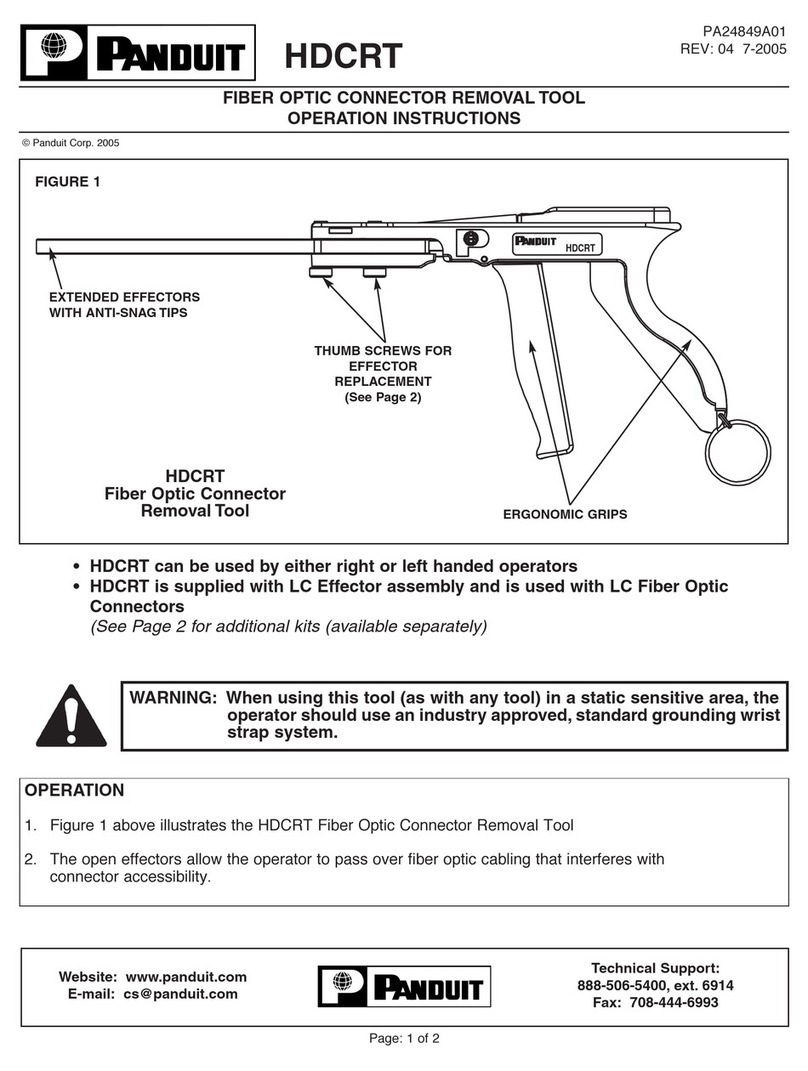

CT-1090 TOOL

Fig. 1

Fig. 2

Stripped

Wire

Crimp Die

Controlled cycle mechanism

prevents tool from opening

before crimp cycle is completed.

Manual release lever, push

forward in the event that

controlled cycle mechanism

must be released.

Cushioned handle grips

C IMP POCKETS for Ferrule

terminals. efer to product

packaging for wire range and

proper crimp pocket. Crimp

pockets are identified with

applicable wire range.

Ferrule - Wire

crimp section

Ferrule Insulated

section

CT-1090

PA28190A01

EV: 00 9-2016

E-mail:

For Technical Support:

1-800-777-3300

www.panduit.com

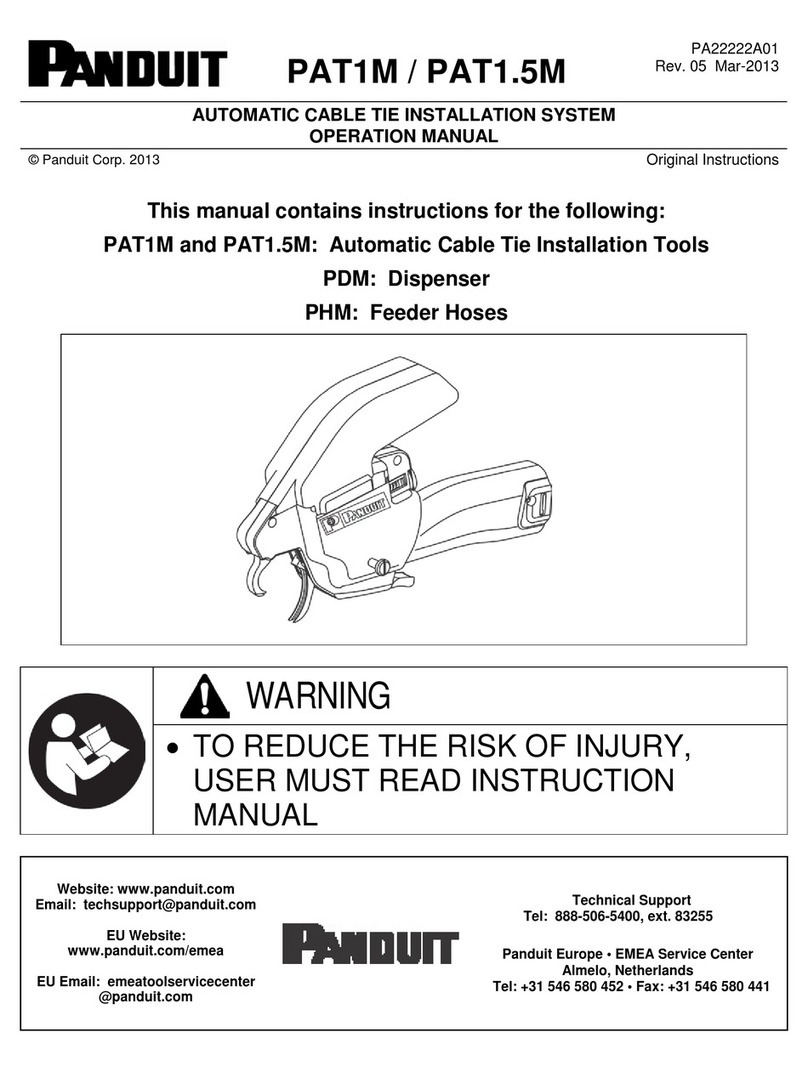

CAUTION:

Verify power is “OFF” before working on

wiring with these tools.

The plastic grips are for the user’s

comfort, and are not intended

to insulate against electrical shock while

working on li e electrical circuits.

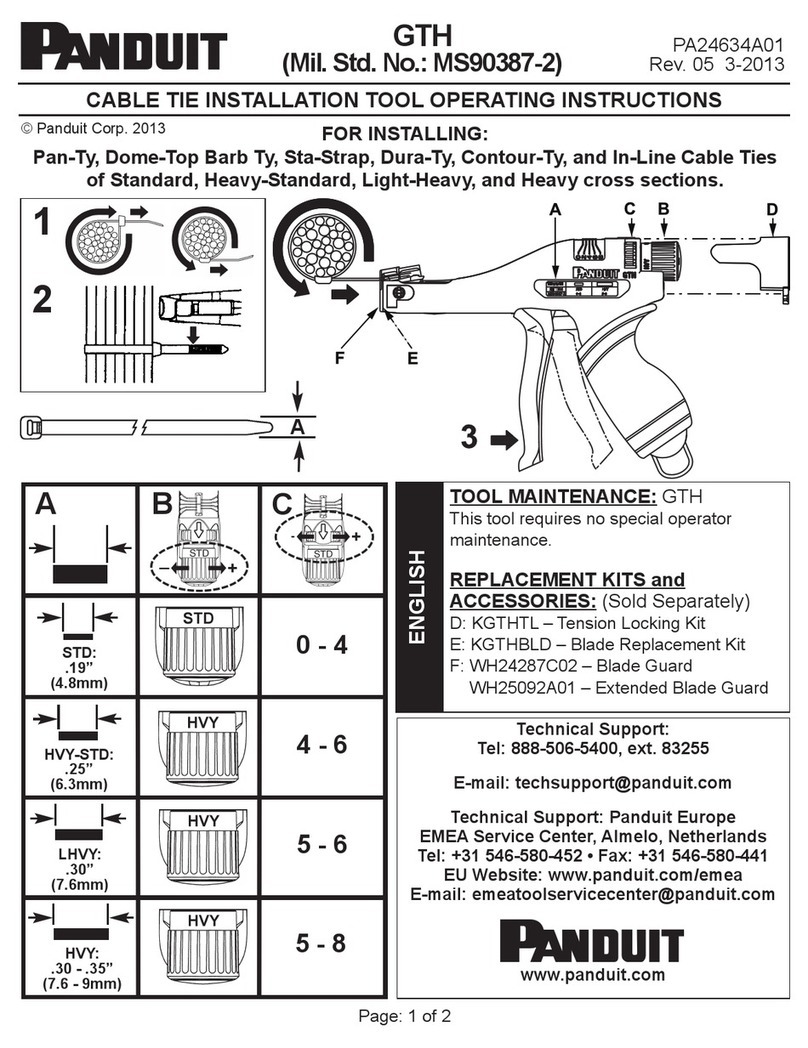

INSPECTION / MAINTENANCE

NEW TOOLS -

BEFORE PLACING INTO SER ICE:

All Panduit crimping tools are inspected before they are

shipped from the factory. All new tools should be

inspected before being used.

New tools are shipped, factory lubricated, in protective

packaging. After inspection, simply clean any excess oil

from the crimping dies and place into service.

When the tool is not in use, keep the handles closed to

prevent objects from becoming lodged in the crimping

area. Store the tool in a clean, dry area.