© Panduit Corp. 2018 OPERATION INSTRUCTIONS CT-400

CT-400: PA24435A01_04 Page: 2 of 4 6-2018

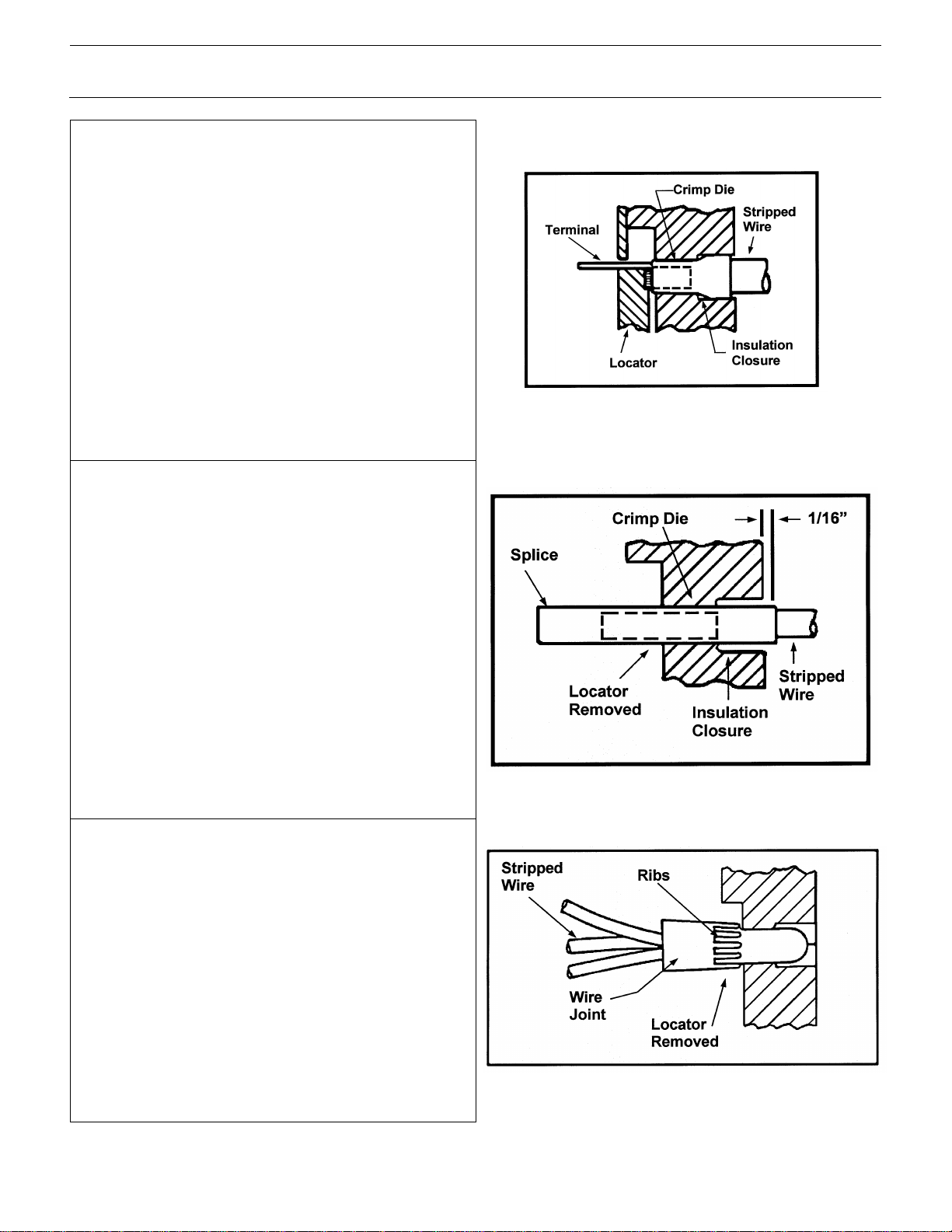

INSULATED TERMINAL INSTRUCTIONS

1. With handles in open position, insert terminal in

proper size die so that tongue slides into locator

slot. See product packaging for proper crimping

pockets.

2. Position terminal against locator and close handles

until barrel is held snugly in place -- do not deform

barrel.

3.

Insert stripped wire into terminal until conductor

extends beyond barrel. See product packaging for

wire strip length.

4.

Crimp by closing handles until controlled cycle

device releases. Handles will open automatically,

and crimped terminal may be removed.

FIG. 3

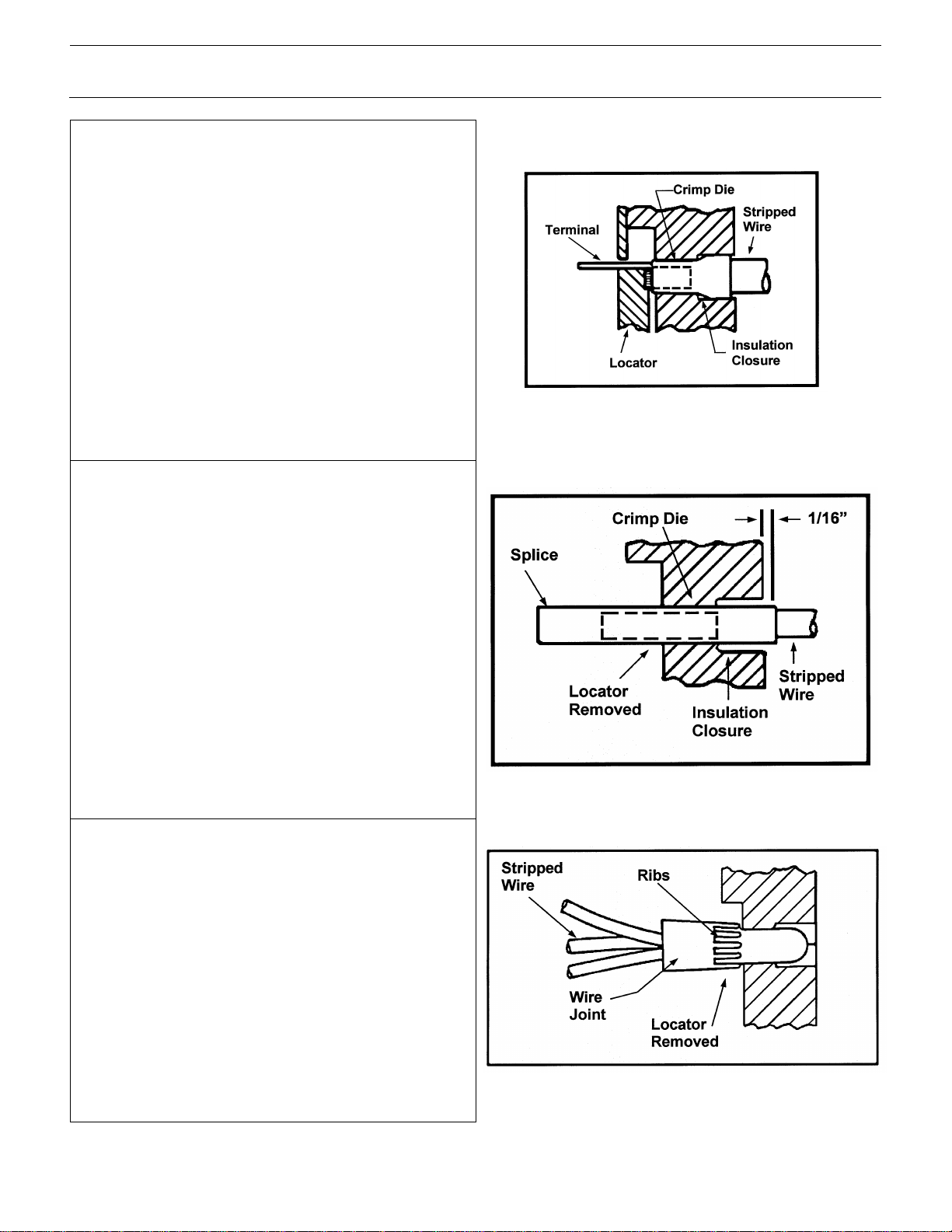

INSULATED SPLICE INSTRUCTIONS

1. Remove locator using a 2mm Allen wrench on the

locator retention screws [see FIG. 1]. (The 2.5mm

wrench may be used simultaneously to secure

screws on opposite side.)

2.

With locator removed and handles opened, insert

splice in proper size die so that barrel extends 1/16"

beyond insulation closures.

3. Close handles until barrel is held snugly in position -

- do not deform barrel.

4. Insert stripped wire into splice and crimp by closing

handles until controlled cycle device releases.

5.

Remove splice and repeat operation for crimping

other half of barrel.

FIG. 4

INSULATED WIRE JOINT INSTRUCTIONS

1. Remove locator using a 2mm Allen wrench on the

locator retention screws [see FIG. 1].

(The 2.5mm

wrench may be used simultaneously to secure

screws on opposite side.)

2.

With terminal locator removed, insert wire joint in

proper size die so that ribs of molded insulator are

positioned against face of tool.

3. Twist ends of stripped wire together, trim and insert

into wire joint.

4. Crimp by closing handles until controlled cycle

device releases. Handles will open automatically,

and crimped joint may be removed.

FIG. 5