C -260

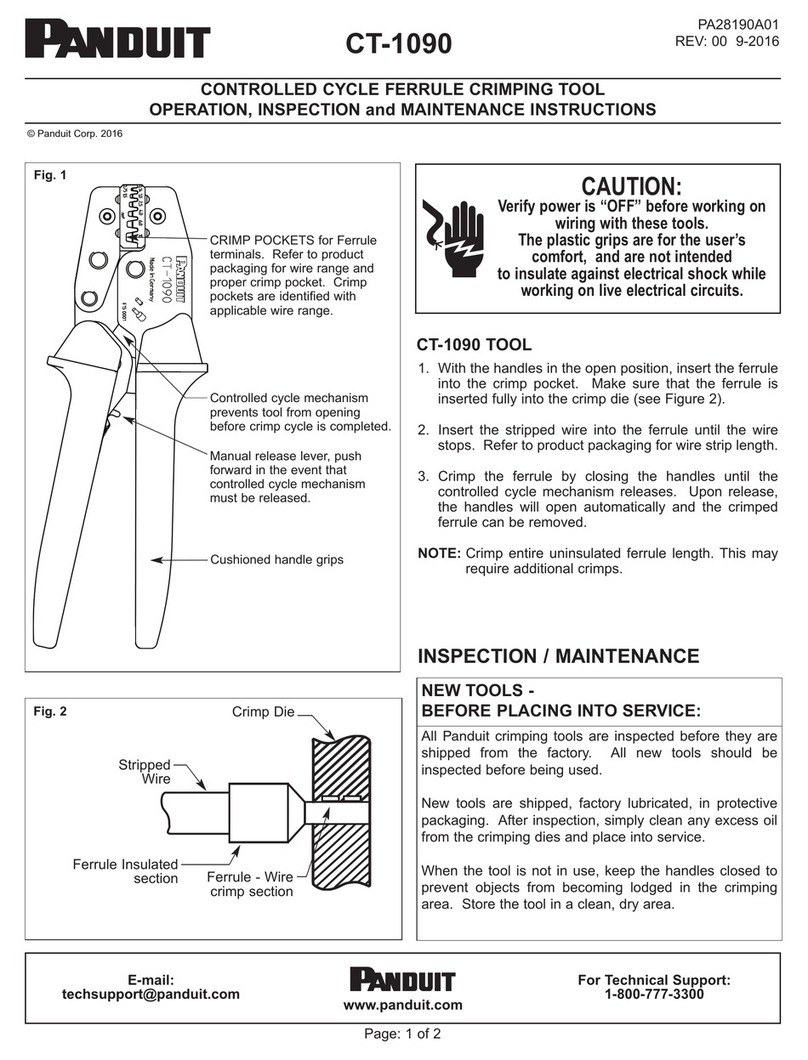

CRIMPING OOL

OPERA ION INS RUC IONS

Page: 1 of 2

PA24429A01

REV.: 02 5-2014

OPERA ION INS RUC IONS

© Panduit Corp. 2014

C -260

For echnical Support:

1-888-506-5400, ext. 83255

E-mail:

techsupport@panduit.com

See product packaging or contact Customer Service for

UL/CSA approved tooling/product combination.

CAUTION:

Verify power is “OFF” before working on wiring with this tool.

The plastic grips are for the ser’s comfort,

and are not intended to ins late against electrical shock

while working on live electrical circ its.

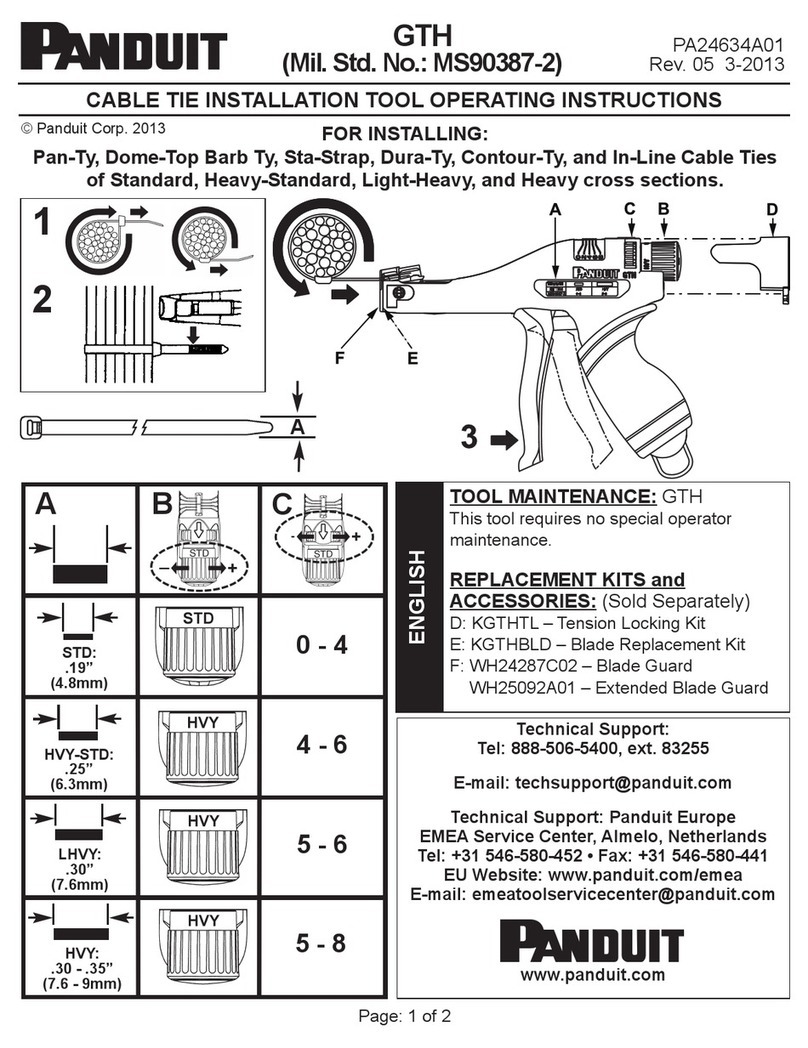

NON-INSULA ED AND INSULA ED

PARALLEL SPLICE

INS RUC IONS

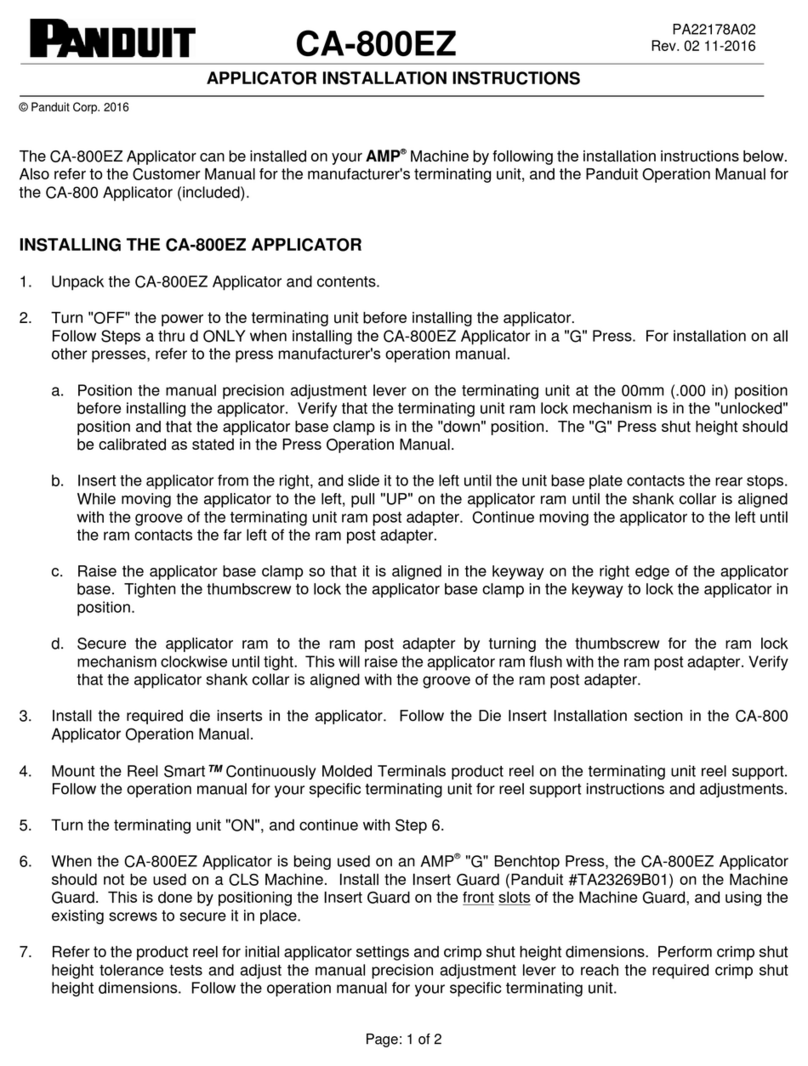

1. Insert stripped wire into each end of the

parallel splice. (See product packaging

for proper strip lengths.)

2. Locate parallel splice in proper crimp

pocket.

3. Position crimp pocket on the center of

the metal barrel.

4. Squeeze handles firmly.

WIRE CU ER for No. 10 AWG and

smaller copper wire.

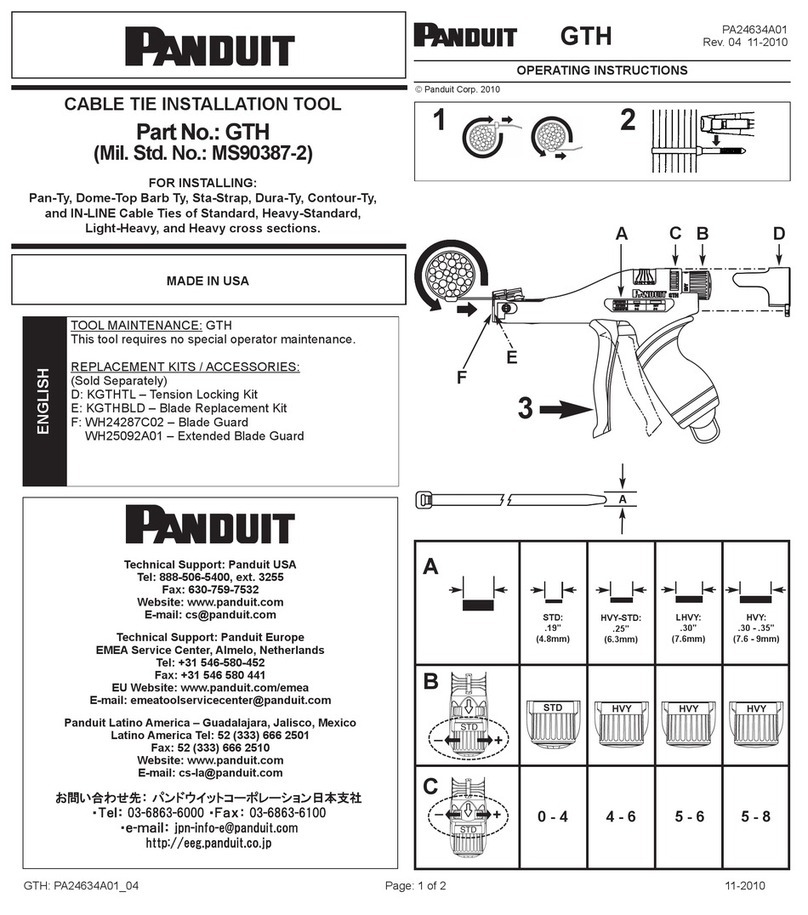

CRIMP POCKE S for Pan-Term

insulated and non-insulated terminals,

disconnects, wire joints and splices on No.

22 to 10 AWG solid or stranded wire.

This tool is made of hardened steel and is

protected with a light coat of oil.

CRIMP POCKET

CRIMP POCKET

NON-INS LATED

INS LATED

www.panduit.com

NON-INSULA ED BU SPLICE

INS RUC IONS

1. Insert stripped wire into end of the butt

splice to internal wire stop. (See product

packaging for proper strip lengths.)

2. Locate butt splice in proper non-

insulated crimp pocket.

3. Position crimp pocket on the center of

the metal barrel half with wire inserted.

4. Squeeze handles firmly.

5. Repeat for other end of butt splice.

INSULA ED BU SPLICE

INS RUC IONS

1. Insert stripped wire into end of the butt

splice to internal wire stop. (See product

packaging for proper strip lengths.)

2. Locate butt splice in proper insulated

crimp pocket.

3. Position crimp pocket on the center of

the metal barrel half with wire inserted.

4. Squeeze handles firmly.

5. Close insulation if desired.

6. Repeat for other end of butt splice.

CRIMP POCKET

CRIMP POCKET