8

DTX10 - DTX80 USER GUIDE

4. Sequence of Operation

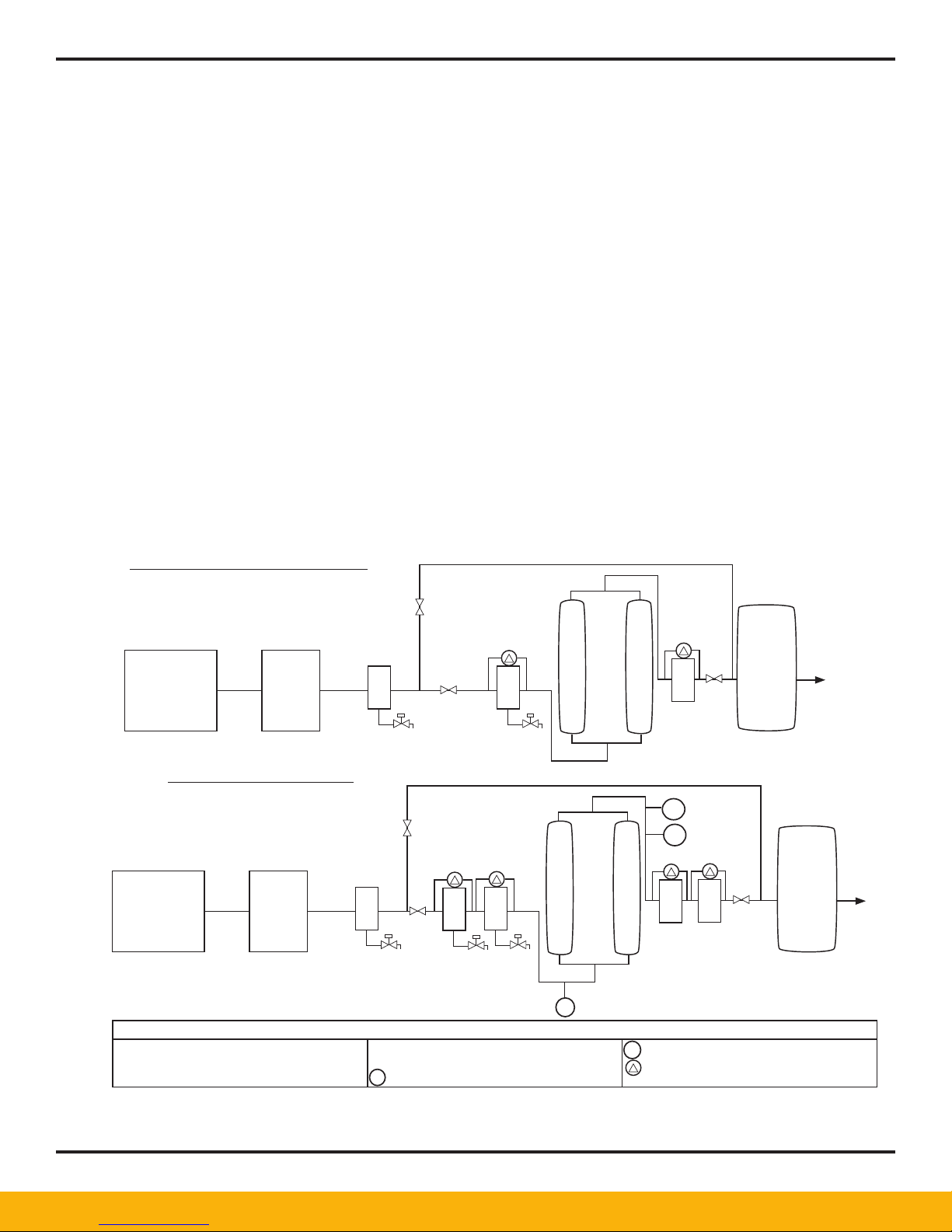

The sequence is controlled by a Solid State Timing and Relay circuit (Sequence Annunciator) which in turn

controls ve electric solenoid valves. The rst four are 3-Way Normally Closed Valves, which supply control

air to operate air operated switching inlet and exhaust valves. The Inlet Valves are Normally Open and are

closed by supplying dry control air to the valve actuator. The Exhaust Valves are Normally Closed and are

closed by supplying dry control air to the valve actuator. The fth solenoid is the repressurization valve.

There are also four mechanical check valves, two outlet and two purge, that allow for proper air ow.

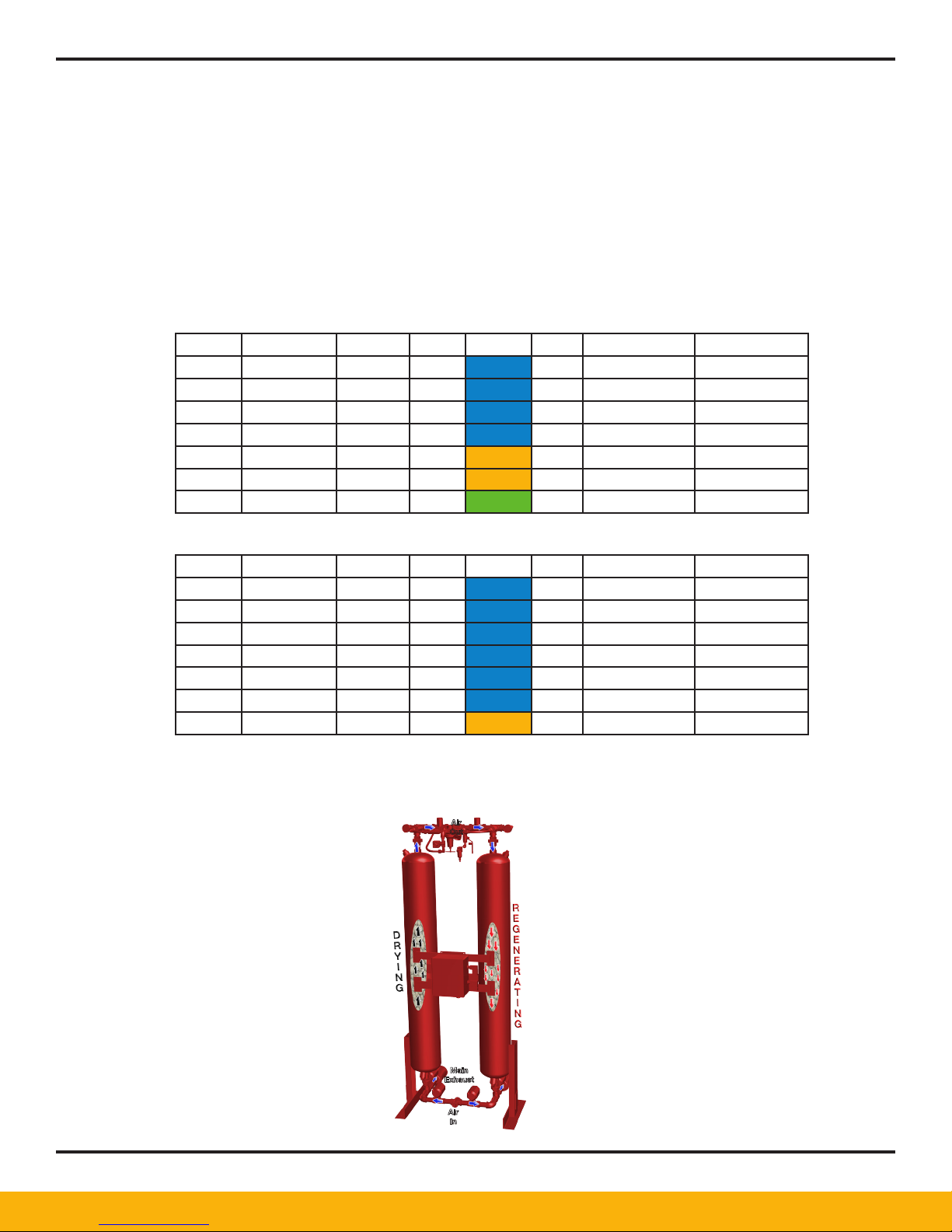

STEP 1- LEFT DRYING; RIGHT REGENERATING

SOLENOID #1 is de-energized sending no air to Exhaust Valve #1 (left side). Exhaust Valve #1 is closed.

SOLENOID #2 is de-energized sending no air to Inlet Valve

#1 (left side). Inlet Valve #1 is open. All of the wet inlet air is owing through Inlet Valve #1. It is dried as it

passes through the left tower desiccant bed and exits out the left side Outlet Check Valve to the dryer out-

let. The left tower is the Drying tower and the associated pressure gauge should read line pressure,.

At the same time SOLENOID #3 is energized sending a signal to Inlet Valve #2 (right side). Inlet Valve #2 is

closed, preventing inlet air ow through the right tower.

SOLENOID #4 is energized sending a signal to Exhaust Valve #2 (right side). Exhaust Valve #2 is open.

(NOTE: When exhaust valve rst opens, the associated tower will depressurize from line pressure to atmo-

spheric pressure.) Purge air will now ow from the dry air outlet through the Purge Adjusting valve, Purge

Orice and the right hand Purge Check Valve. This purge air then proceeds through the right tower near

atmospheric pressure, removing the moisture and exiting the right hand Exhaust Valve and Mufer in vapor

form (at no time should the dryer expel any signicant amount of liquid water from the mufer; this is a sure

sign of trouble in the system). The right tower is the regenerating tower, the associated pressure gauge

should read “0” PSIG.

SOLENOID #5 is de-energized and closed.

STEP 2 - LEFT DRYING, RIGHT REPRESSURIZING

While the left tower is still drying, Solenoid #4 will de- energize, relieving the control air signal on the right

exhaust valve, returning that valve to its normally closed state. Closing this valve keeps air in the tower, al-

lowing the depressurized part of the dryer to build up pressure or “repressurize”. At the same time Solenoid

#5 is energized and opened, providing additional air to the tank coming from the purge line to ensure full

repressurization of the dryer. Prior to switching towers, all of the gauges should equalize to line pressure.

STEP 3 - LEFT REGENERATING, RIGHT DRYING

Step 3 is the reverse of step 1. Solenoid #1 is energized, providing control air to and opening the left ex-

haust valve.

Solenoid #2 is energized, providing control air to and closing the left inlet valve. Solenoid #3 and #4 are

de-energized. Thus the right inlet is open, and the right exhaust is closed. All the wet air is now owing

through the right tower and is being dried at line pressure. The left tower is being regenerated at

atmospheric pressure. Solenoid #5 is de- energized and closed.

STEP 4 - LEFT REPRESSURIZING, RIGHT DRYING

Step 4 is the reverse of Step 2. Solenoid #1 de-energizes, allowing the left exhaust valve to close and al-

lowing the dryer to repressurize. In addition, Solenoid #5 energizes providing additional air for repressuriza-

tion.

NOTE: The Purge Gauge (middle) should read purge pressure, except during repressurization. Purge pres-

sure for standard inlet design conditions is listed on page 4. For other than standard or design conditions

consult the factory.