1

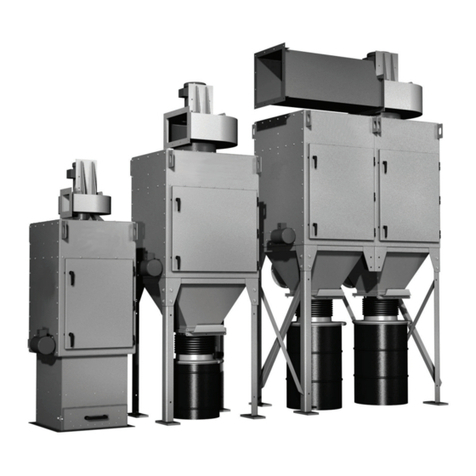

SMOG-HOG Electrostatic Precipitator PCN Series

COMBUSTIBLE DUST HAZARDS –

SMOG-HOG®and DUST-HOG®Pollution Control Systems

Pursuant to National Fire Protection Agency (NFPA) Standards, the owner/user is required to test their dust mixtures

to evaluate and understand potential combustion or deflagration hazards that may exist. In addition, NFPA standards

require the owner/user to perform and have record of a Dust Hazard Analysis (DHA) if there is potentially a combustible

material involved within or exposed to the process.

The DHA serves as a systematic review of the process to:

1) Identify where fires and explosions can occur;

2) Identify the potential causes and consequences, and;

3) Determine if existing and proposed safeguards are sufficient.

It is the responsibility of the owner/user to evaluate, interpret and document any associated risk in their process

including adherence and compliance to any and all applicable local, state and federal codes, standards, laws and

regulations.

It is the sole responsibility of the equipment owner/user of record to coordinate and perform sample material collection

and combustion/explosivity testing of any and all dust and material that will be extracted and filtered by the Air Pollution

Control (APC) filtration equipment and to notify Parker of the results prior to any discussion involving equipment

specification and solution recommendation. It is recommended to utilize a Certified Industrial Hygienist (CIH) or certified

safety expert that is properly trained, licensed and approved and to use a licensed and approved dust testing facility

for proper dust and material analysis, testing protocol and reporting procedures. A sample of testing facilities and list of

Industrial Hygiene (CIH) and other occupational and environmental health and safety (OEHS) consultants can be located

through AIHA (American Industrial Hygiene Association) website.

To minimize the risk of fire or explosion, user must ensure proper installation, operation and maintenance of Parker

equipment. Since application, installation, operation and maintenance are beyond the control of Parker, Parker disclaims

any liability or responsibility for damage from fires or explosions regardless of origin. Parker recommends that all APC

dust collection equipment, installation and application conform to any and all applicable local, state and federal

standards, codes, laws and regulations including the addition of appropriate fire or explosion protection systems

including but not limited to venting, mitigation, suppression and isolation when and where required. Installation of

Parker equipment should be by a licensed contractor that is also experienced in potential fire and explosion hazards

and adheres to related local, state and federal codes, standards, laws and regulations. Parker is not an expert nor

certified design consultant in relation to spark, fire or explosion mitigation including but not limited to detection,

mitigation, suppression and isolation pf combustible dusts and materials. Therefore, Parker recommends that any

industrial air filtration system recommendation, design or solution be reviewed, approved, stamped and signed by

an industry expert consultant in air filtration systems, combustible dust/materials or certified safety expert such as a

Certified Industrial Hygienist (CIH) or a Certified Professional Engineer (PE) who is a licensed and certified expert with

industrial filtration system design and application including adherence and compliance to any and all applicable local,

state and federal codes, standards, laws and regulations.

Pursuant to Parker’s Offer of Sale (terms and conditions) and by accepting the purchased equipment, Buyer and owner/

user agree to defend, indemnify, and hold harmless Parker, its successors, assignees, suppliers, shareholders, directors,

officers, employees, agents, and affiliated companies from all losses, costs, damages, demands, claims, liabilities, fines,

penalties or any other expenses (including attorneys’ fees, court costs, and expert fees) (collectively “losses”), caused or

contributed to in any way by Buyer or owner/user’s failure to follow these instructions and/or failure to properly install,

apply, operate, or maintain the equipment purchased from or supplied by Parker, or losses caused or contributed to in

any way by Buyer’s and owner/user’s failure to provide accurate information, specifications or dust explosivity values.