3

8902/RE Resolver Speed Feedback Option

Figure 3 Rear of

Control Board

A

B

B

A

Installation

Fitting the Option

If the Option is not factory-fitted, follow the procedure

given below.

WARNING!

Disconnect all sources of power before

attempting installation.

Caution

This Option contains ESD (Electrostatic Discharge)

sensitive parts. Observe static control precautions

when handling, installing and servicing this Option.

1. Undo the two screws securing Option A and Option B

to the front of the drive. If Options are not fitted,

completely remove the blank covers for the Option A

and Option B slots.

2. Undo the screws (A) located in the top and bottom

handles of the control board. Gently pull on the

handles to withdraw the board from the drive,

supporting any attached option boards. Note that the

boards are sliding in top and bottom slots.

3. Remove any other Options that are fitted to the control

board.

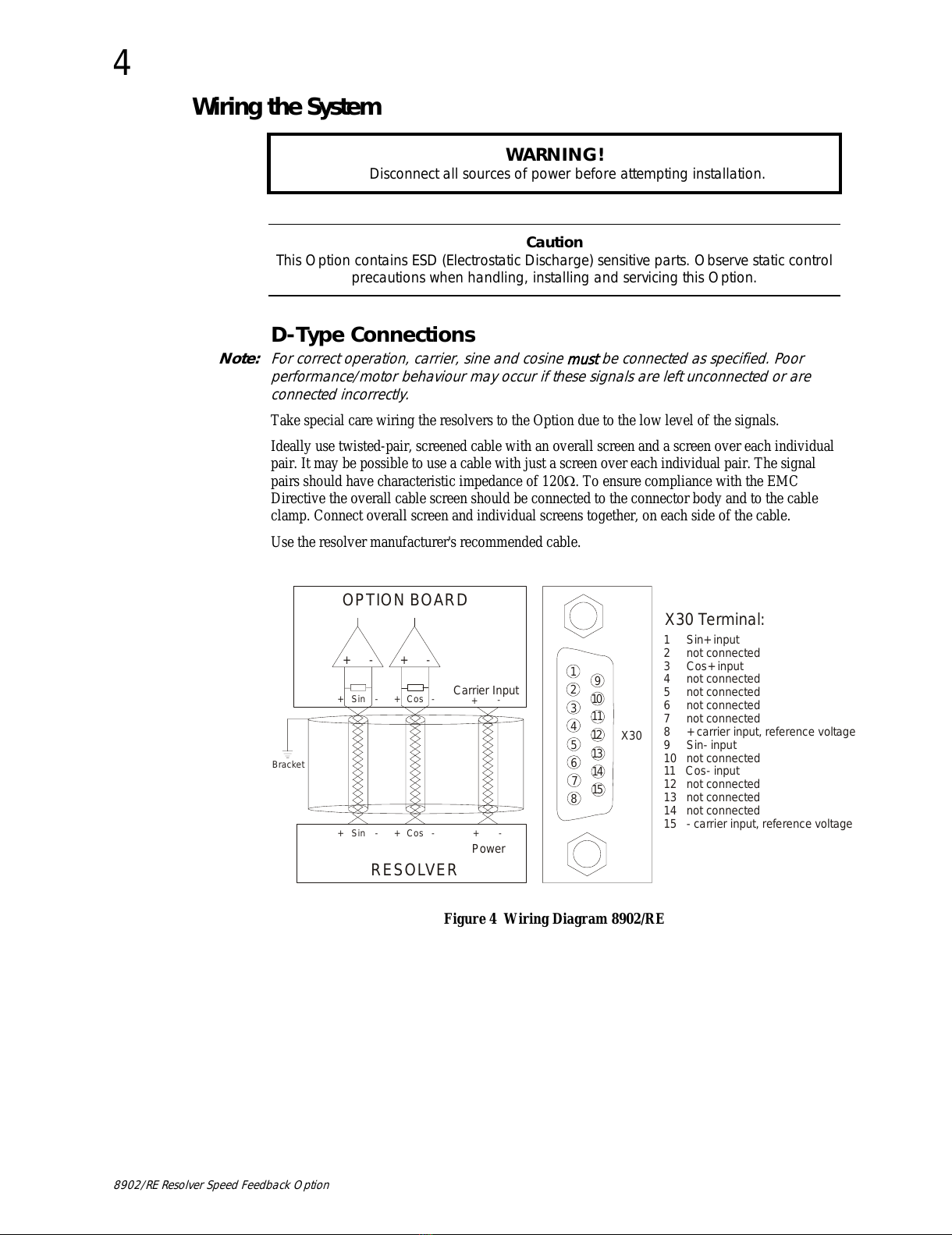

4. Offer up the Resolver Option through the "OPTION F"

cut-out as shown opposite.

5. Fit the two locating pegs of the large connector on the

rear edge of the option board into the locating holes on

the control board, as shown below.

6. Fit the two screws and crinkle washers (C) at the rear edge of the Option.

DO NOT OVERTIGHTEN.

Tightening torque : 0.2Nm (28 oz-in).

7. Secure with the two screws (B) to the front of the control

board.

The front panel screws (B) are self-tapping and can be

quite hard to turn. This turning torque must not be

transferred through the option board to the control board

connector. To avoid this hold the option board with one

hand, while tightening the front panel screws with the

other. DO NOT hold the control board while tightening

these screws.

8. Refit any other Options that were removed from the control

board.

9. Replace the control board (with attached Options) into the

drive.

10. Tighten the Option A and Option B screws; or importantly,

fit the blank covers and secure with the screws.